The inventory scrap feature of the system is a key component of effective Odoo inventory control and waste tracking, enabling businesses to isolate damaged or unusable products without compromising accurate stock reporting. This scrap inventory functionality serves as a virtual buffer zone where scrapped items are moved instead of being deleted, maintaining transparency across warehouse operations and ensuring that all losses are traceable for both operational and accounting purposes. This isolation helps separate waste from usable inventory, reducing confusion and potential misstatements in real-time stock analysis.

Products can break during production, components might get damaged in transit, or raw materials might expire on the shelf. Without a proper scrap management process, such issues often lead to confusion, inventory mismatches, or incorrect accounting entries. Accounting for scrap inventory provides a streamlined workflow that allows teams to remove such items from usable stock without actually erasing their existence from the system. As the Odoo scrap processes are fully embedded into inventory and manufacturing modules, users can initiate scrap actions in Odoo directly from stock transfers, manufacturing orders, work orders, or the shop floor dashboard.

A clear inventory scrap strategy improves efficiency, reduces risk, and enforces best practices across stock operations. When combined with the Odoo inventory tutorial and Odoo Accounting, this feature is not only about removing waste but also about turning operational flaws into opportunities for growth.

Odoo Scrap Inventory Report:

Turning Scrap into Action

All virtual scrap movements are logged and can be analyzed via Odoo's Inventory Valuation and Cost Analysis reports, offering full visibility into recurring losses, supplier quality issues, or production bottlenecks. Implementing the Odoo inventory report features brings essential improvements to how businesses manage waste, maintain inventory accuracy, and ensure operational transparency. This feature enables fast and reliable scrap inventory accounting, reduces manual errors, and gives managers clear visibility into where and why stock losses happen. Regardless of industry or company size, implementing standardized scrap flows helps build long-term operational resilience.

Faster Scrap Item Handling

Instead of making manual stock adjustments or removing items directly from inventory, employees can use a standardized scrap workflow with just a few clicks. Scrap product actions can be triggered during production, from stock moves, or directly on the shop floor – speeding up operations while keeping logs accurate.

Simplified Waste Management

Scrap inventory management rules can be applied to both finished goods and raw materials. Operators don’t have to rely on direct edits or individual decisions, so every scrap document is recorded in the correct virtual scrap location. Whether it’s a broken tool, expired product, or returned item, the system ensures these losses are recorded properly and in the correct scrap location.

Actionable Inventory Report Odoo

Odoo scrap movements are fully traceable, allowing businesses to understand where losses come from. Managers can filter reports by product, location, user, or scrap reason. This turns scrap data into actionable insights, helping improve quality control and reduce recurring damage.

Optimized Scrap

Inventory Workflows

Multi-location companies or businesses with multiple teams benefit from consistent scrap procedures. Once set up, everyone scraps the same way—using designated virtual scrap areas and predefined loss categories. This removes guesswork, improves training, and reduces miscommunication between departments.

Improved Accuracy in Stock

Scrap and Accounting

Every scrap movement reduces inventory in real time, but keeps a historical trail. This ensures correct inventory valuation, supports internal audits, and integrates cleanly with scrap sales accounting.

Fewer Manual Errors

Structured scrap inventory flows reduce the risk of untracked losses, double-counting, or incorrect edits. By following built-in workflows, users minimize risk and boost data reliability.

Scrap Inventory Management for Accurate Inventory Control

To manage damaged, expired, or unusable products, Odoo 18 provides a built-in scrap sales procedure. Before using it, ensure that your warehouse configuration includes at least one designated scrap location. This special virtual scrap location allows you to remove products from stock without affecting your financial inventory, ensuring clean and accurate inventory reporting. Whether you run a manufacturing line, a retail warehouse, or a food supply chain, scrap overview streamlines quality control, minimizes inventory discrepancies, and supports compliance with internal and regulatory standards. This is particularly important in industries with strict traceability requirements, such as pharmaceuticals, food production, and electronics. Activating this function ensures that faulty or rejected items are correctly tracked and excluded from available stock.

-

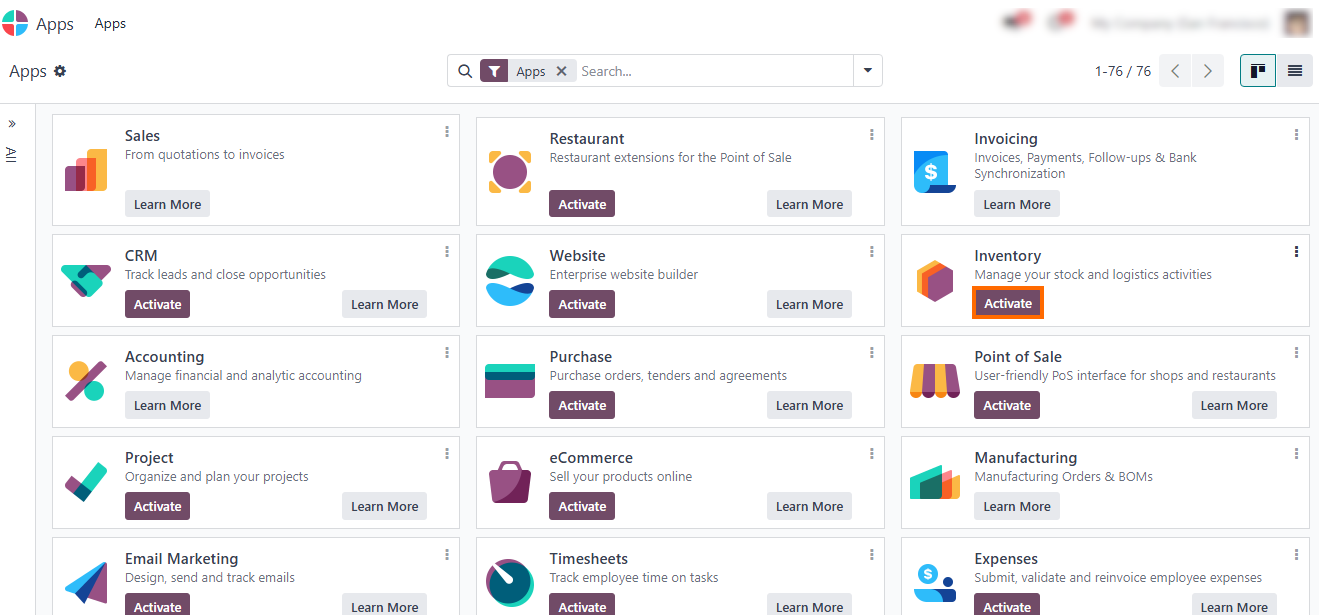

First,

go to Apps and activate the inventory module

in Odoo to enable inventory costing

capabilities, as shown

in the screenshot.

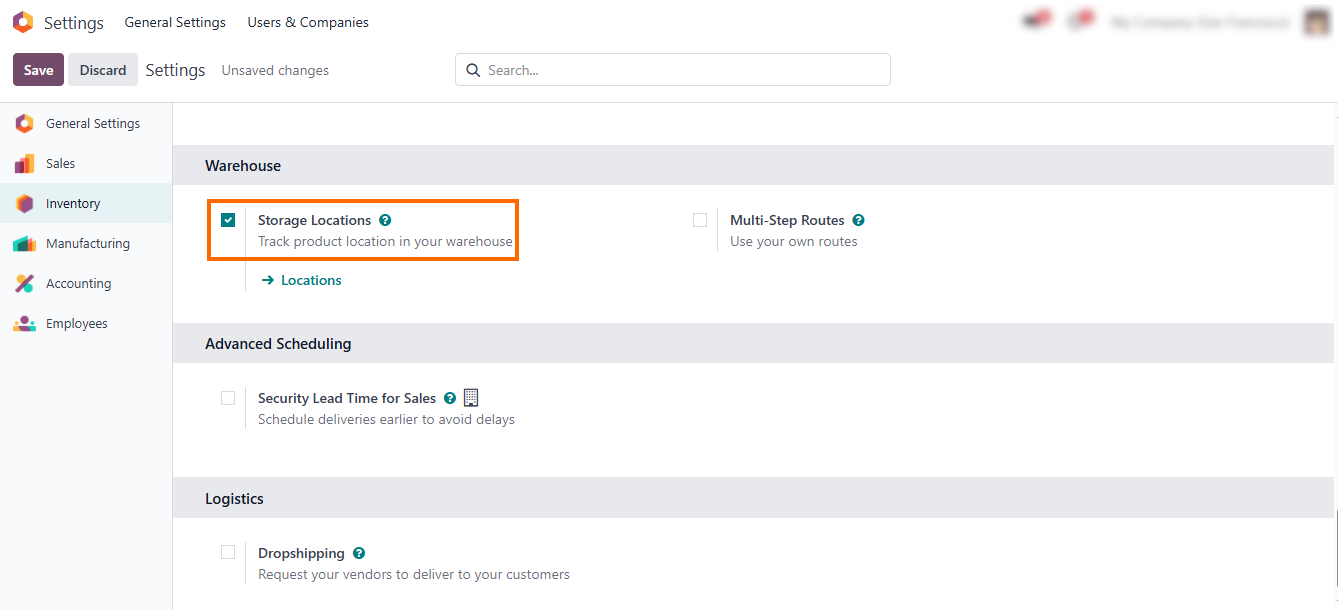

- Then open Settings and select the "Inventory Module". Under the "Warehouse" section, activate the option "Storage Locations".

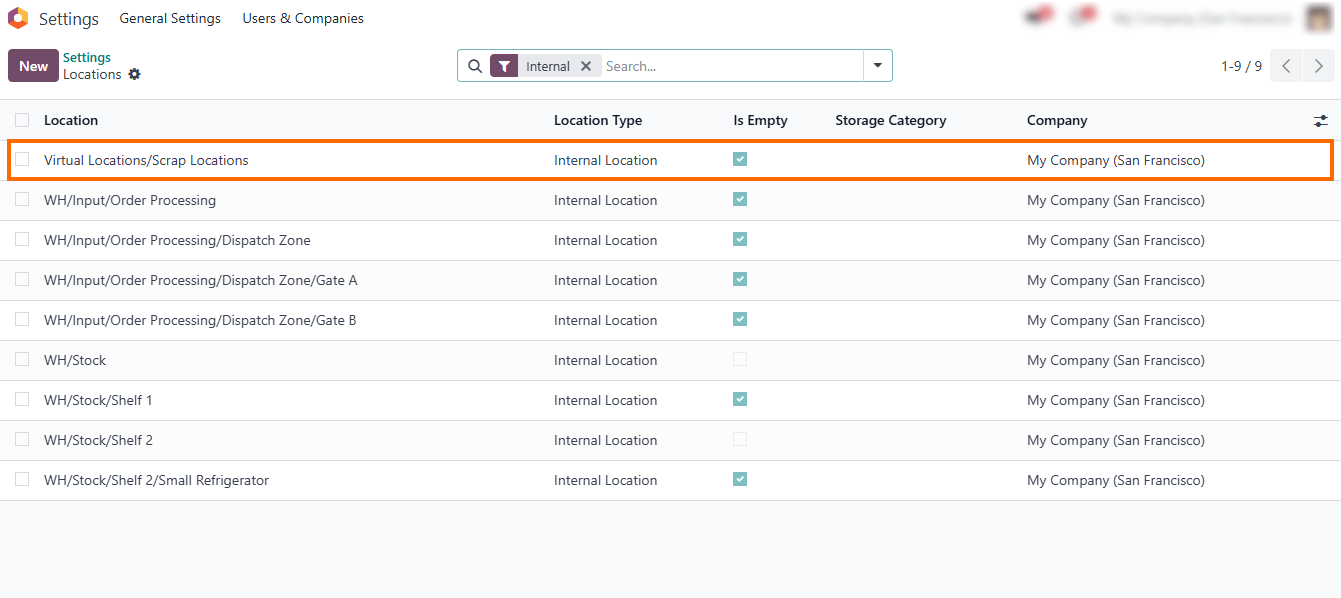

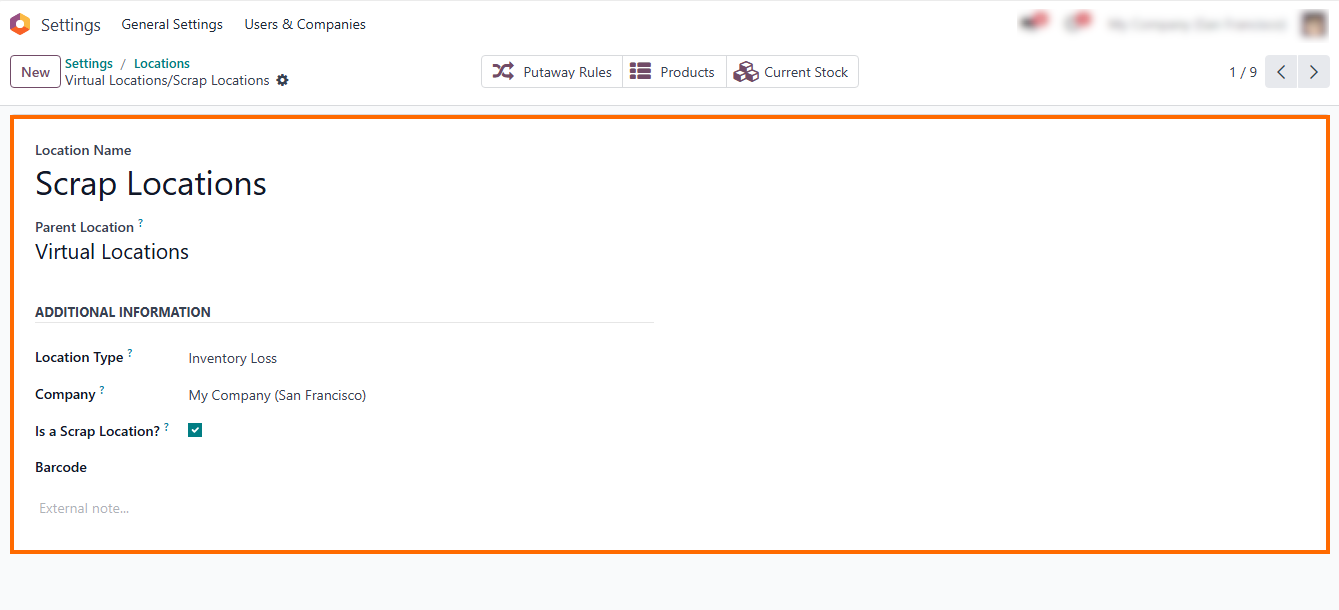

- Once activated, go to "Configuration", and create a new scrap location or search for an existing one.

- This setup ensures products moved into sales scrap areas, won’t impact inventory valuation but remain traceable – supporting clean and accurate Odoo inventory report.

How to Configure Scrap Sales Process in Odoo 18

Once the scrap location is saved, it becomes available across all relevant scrap operations. You can now trigger scrap actions from receipts, internal transfers, manufacturing orders, or work orders. This example demonstrates how scrap doc handles unusable stock using a purchase of 20 units. System features will automatically move the selected quantities to the scrap items for sale, update real-time stock levels, and preserve a full trace of the action. This ensures your inventory data remains accurate while keeping a clear record of where, when, and why product losses occur. Scrap sales process movements are visible in both inventory history and product moves, making them fully audit and ready for future reporting or root-cause analysis.

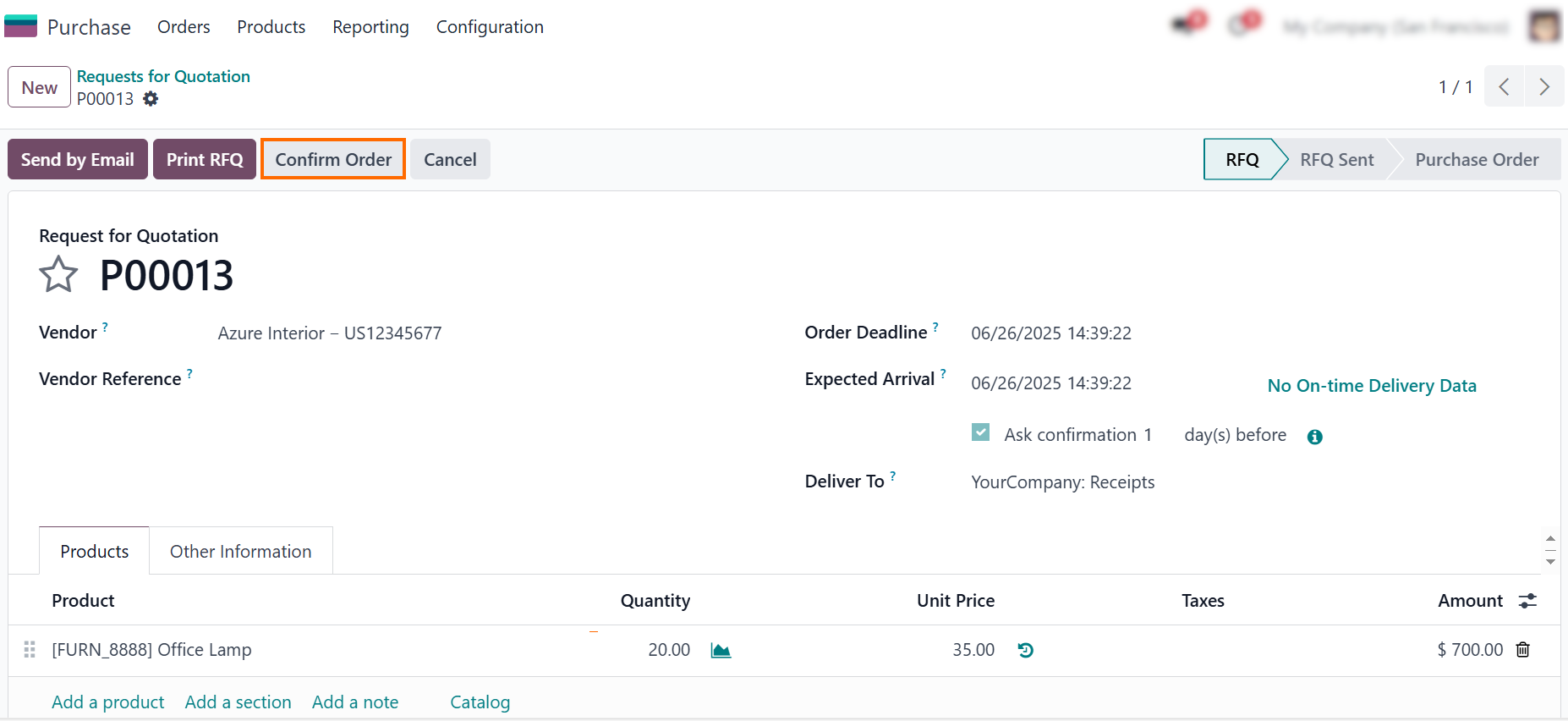

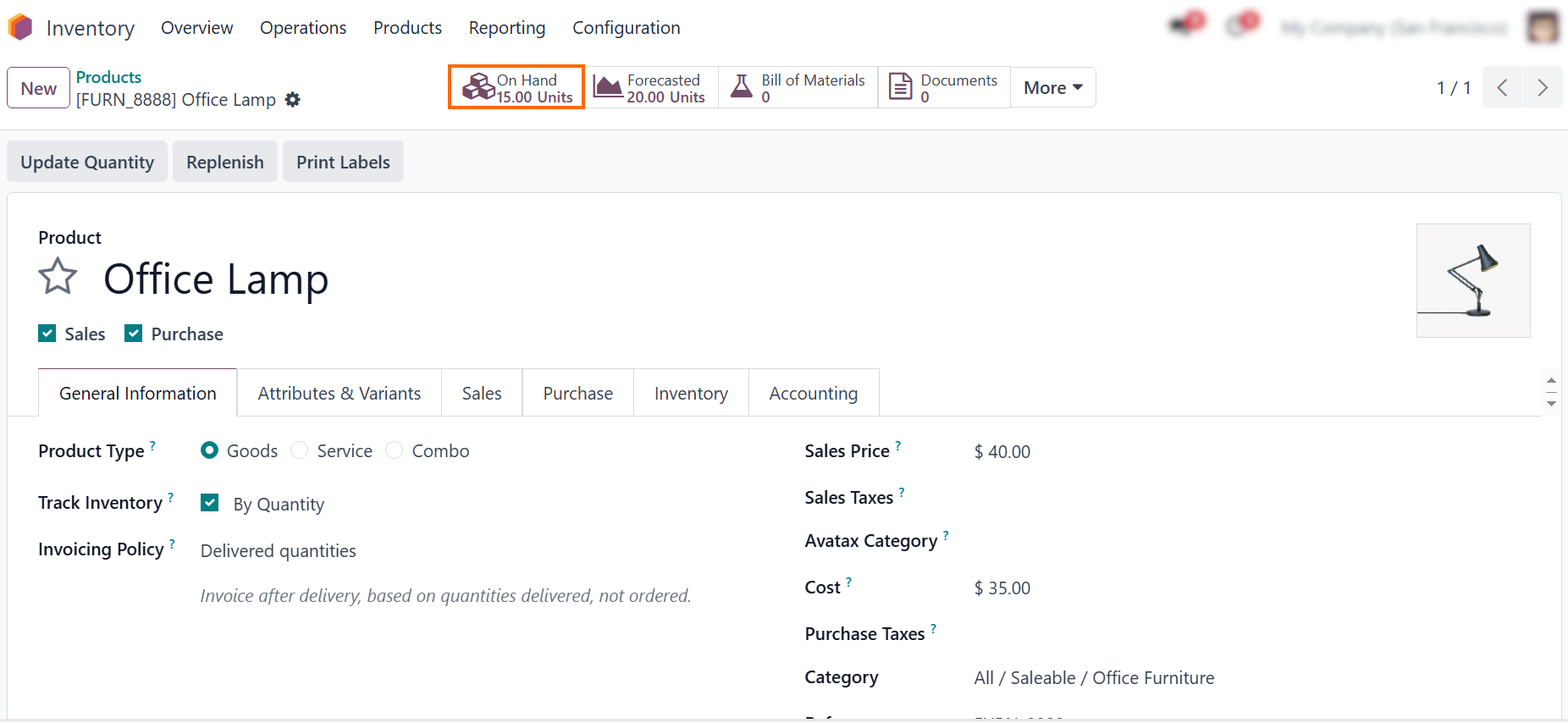

- To demonstrate the scrap location workflow, simulate a purchase of an out-of-stock item to track its movement.

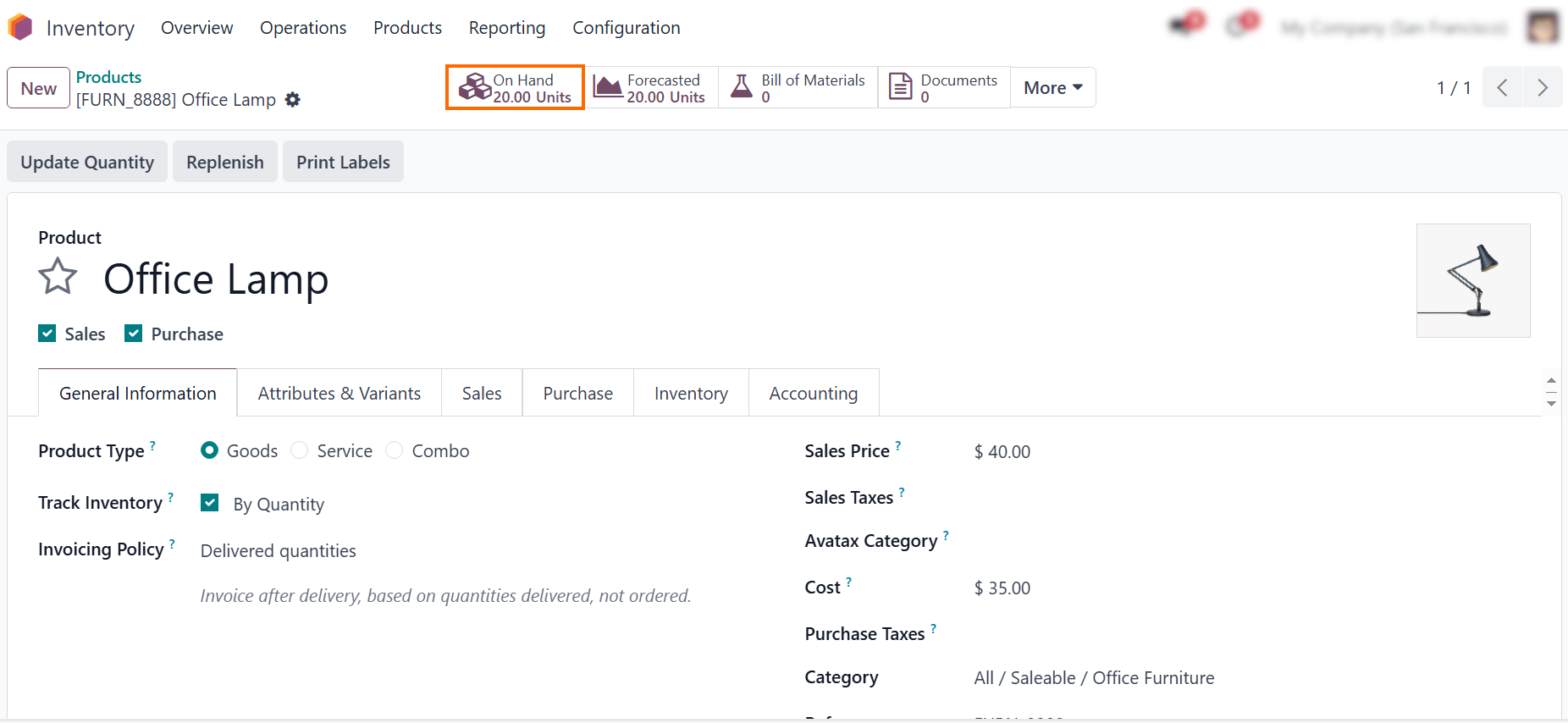

- The updated on-hand quantity will reflect the receipt, allowing you to initiate scrap sales actions directly.

Scrapping Inventory During Sales Operations in Odoo 18

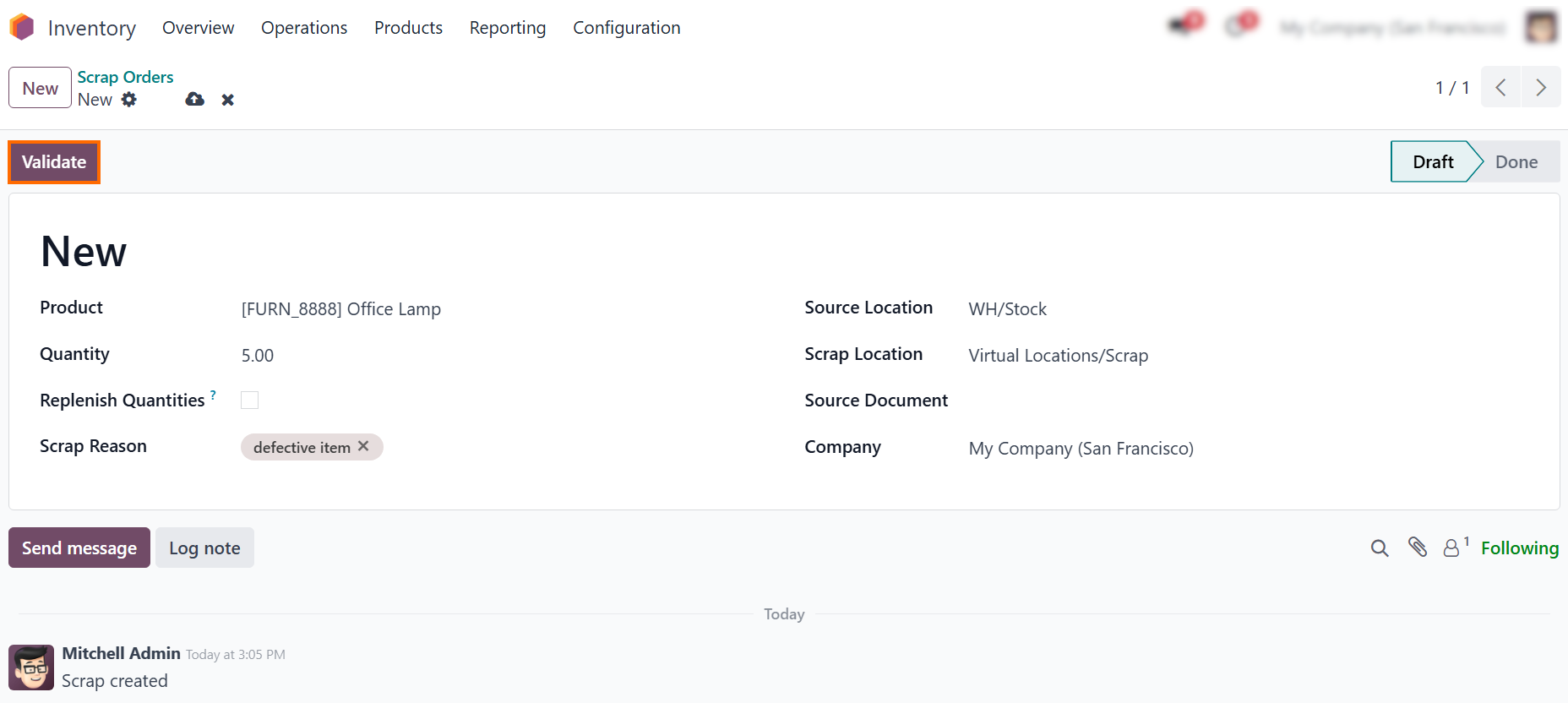

In the first example, some of the purchased items turn out to be damaged upon receipt. At this stage, the focus shifts to identifying which units need to be scrapped. This feature opens a scrap form where users can select the product, specify the quantity to scrap, choose the correct scrap location, and set the reason. Once confirmed, the system automatically registers the movement and updates stock levels accordingly. When scrapping inventory, all items at once, quantities are deducted from available inventory and clearly recorded in product moves. This ensures accurate stock valuation and provides full traceability for auditing and reporting purposes. Users also have the option to attach notes or photos to the scrap record, enhancing documentation for future reference or quality control.

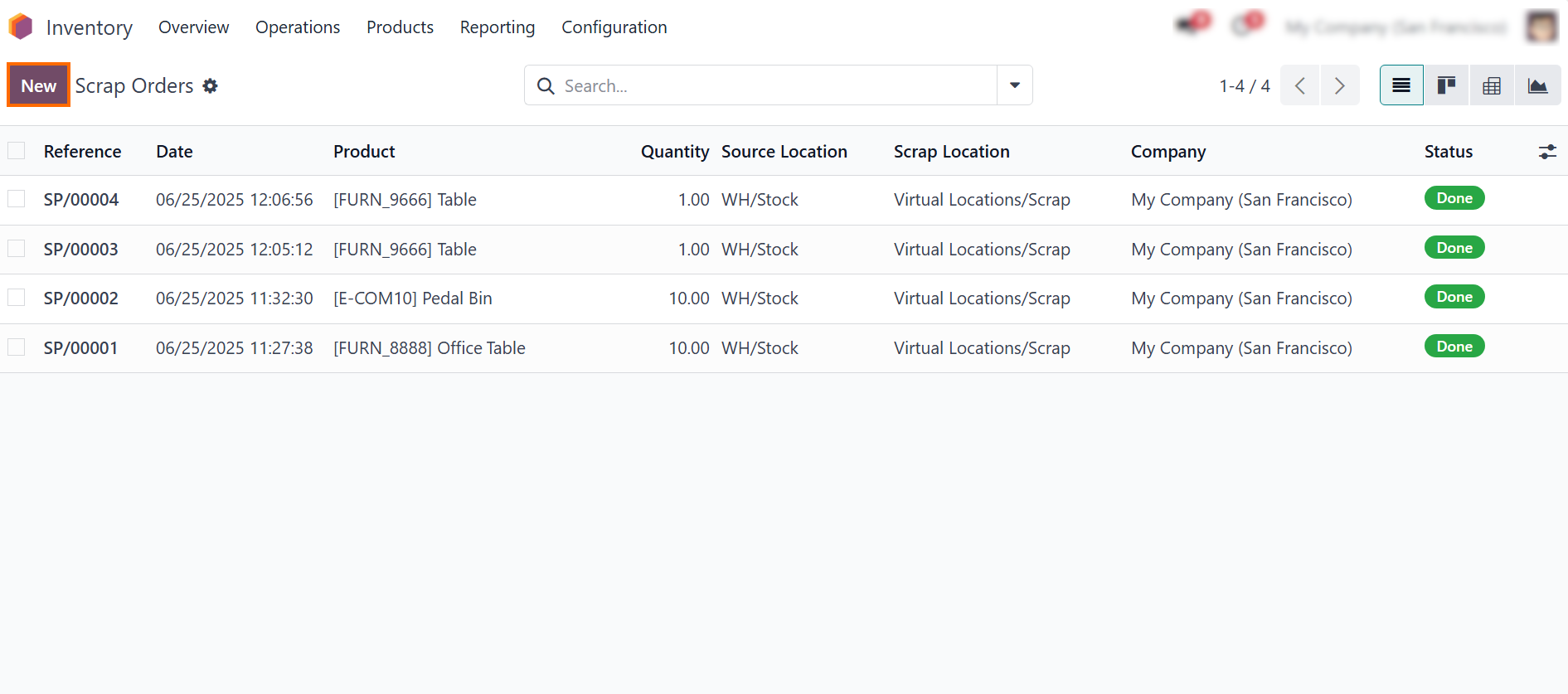

- To start scrapping inventory we have just received, go to the "Inventory Module", navigate to "Operations", then click "New".

- Select the scrap object, enter the quantity, select the appropriate scrap location and specify the reason, then click "Validate" to confirm the operation.

- The "On Hand" tab reflects the updated stock levels – in this case, reduced by 15 items, ensuring inventory in Odoo remains accurate and aligned with the real warehouse conditions.

Scrapping Inventory During Manufacturing

Operations

Scrap sales operations are also critical in manufacturing operations, where defective components, production errors, or failed quality checks often lead to unusable products. Odoo 18 allows users to initiate scrap product operations directly from the manufacturing order or a related work order, ensuring fast and traceable removal of faulty items from the production flow. The scrapped inventory quantity is logged against the specific Manufacturing Order, and the action appears in product moves and inventory history, complete with a reason and timestamp. As a result, teams gain better control over production quality, minimize waste-related confusion, and improve compliance with internal procedures or ISO standards. Now that the workplace setup is complete, we can proceed directly to scrapping inventory operations.

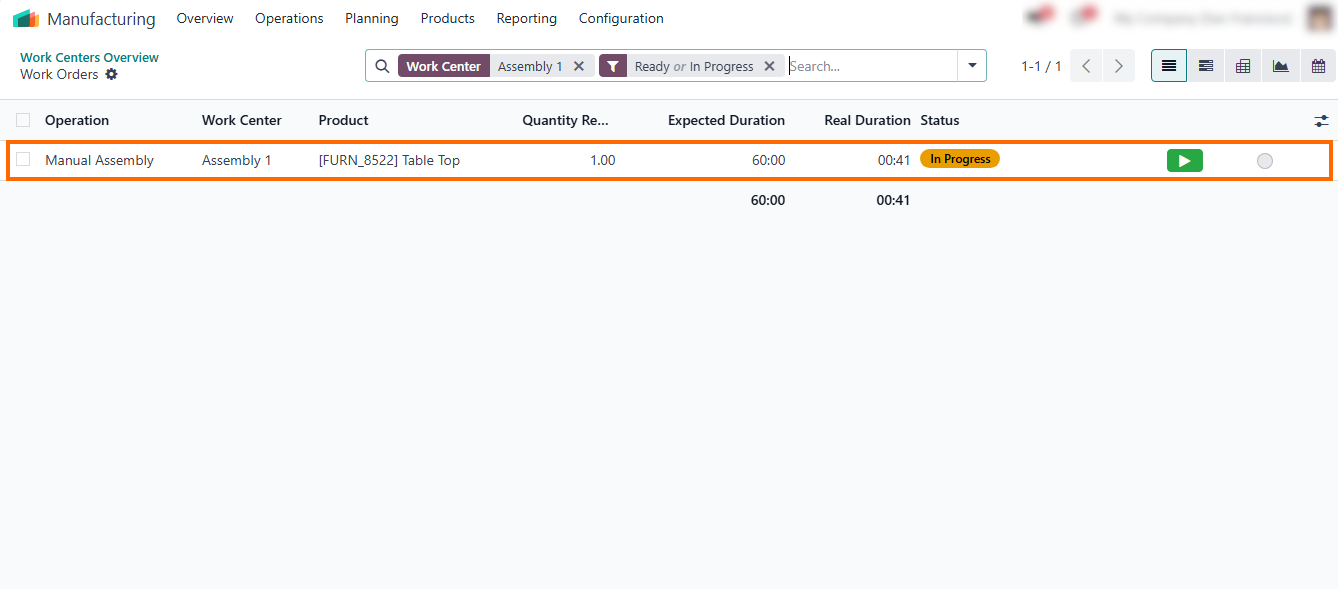

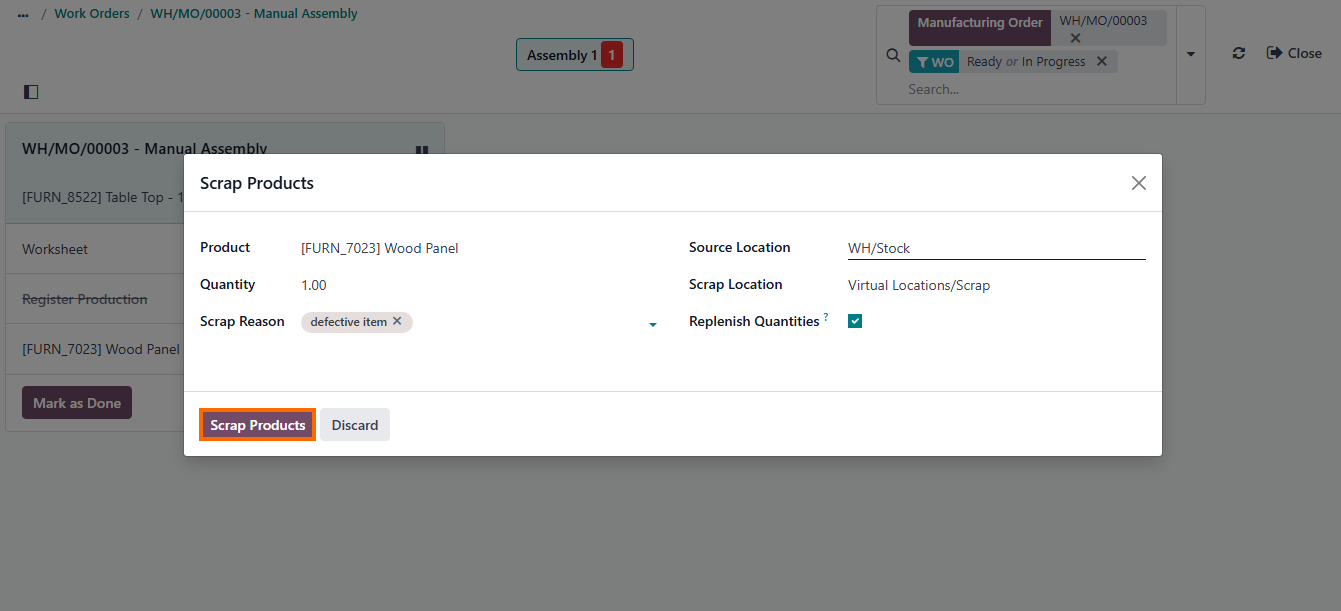

- Go to the "Manufacturing" and open an existing Order, where the issue requiring scrapping has occurred.

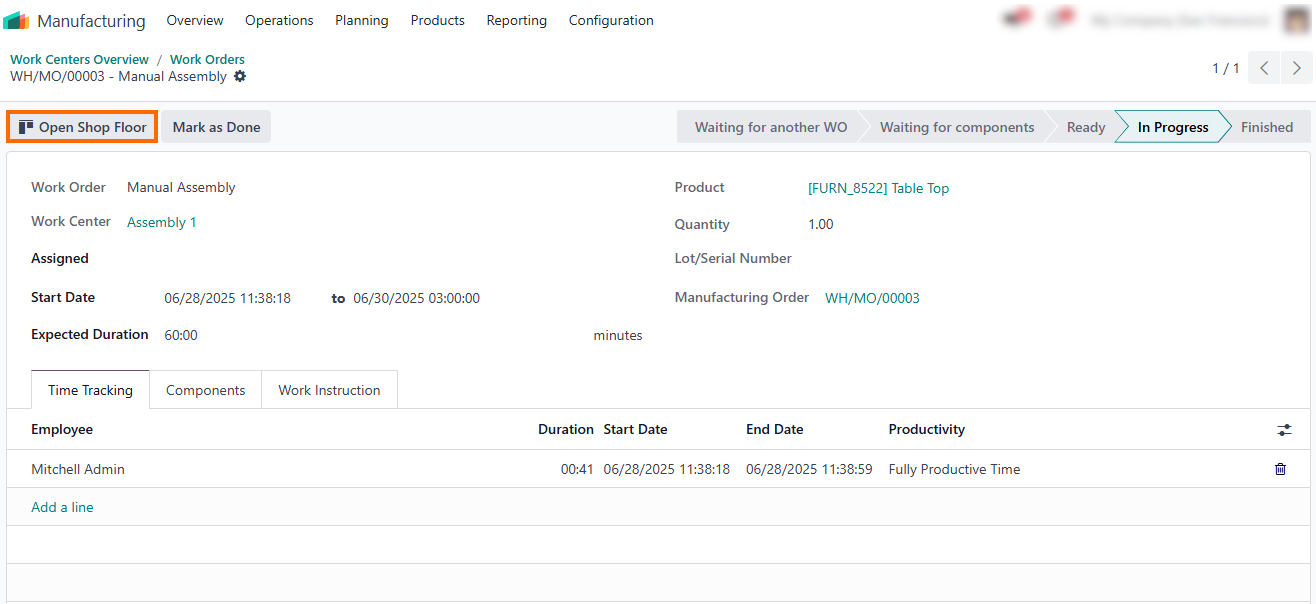

-

Then click "Open Shop Floor" to access the interactive work order

interface, where

scrapping inventory actions can be performed

directly on the relevant production step.

- Select the scrap product, set the quantity, choose the appropriate scrap location, and define the reason for scrapping inventory.

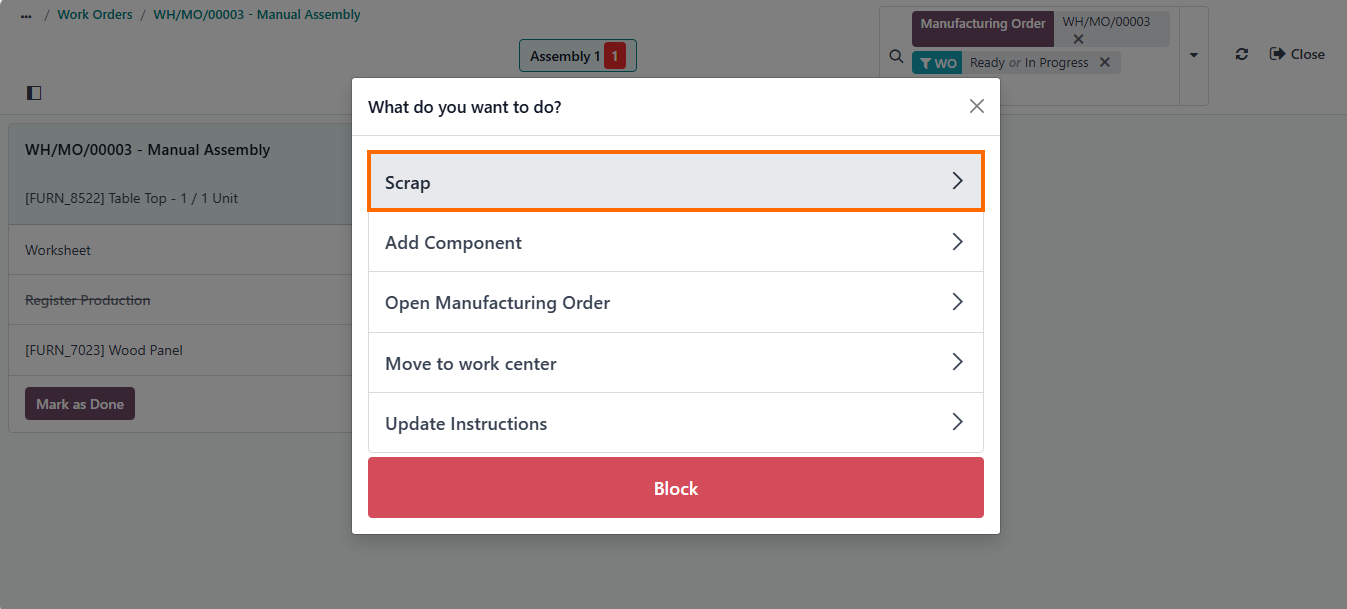

-

Click "Scrap Product" to

confirm the operation. The system will automatically remove the

item from production, update stock levels, and log the movement for

traceability.

Powering Data-Driven Inventory with Odoo Scrap Analytics

Odoo scrap features provide inventory managers with the visibility they need to monitor losses and take control of the quality of scrap products. With built-in reporting and traceability tools, businesses can transform scrap a shop movement into actionable insights. Whether tracking damaged goods, expired materials, responsible users, or scrap reasons, managers can detect patterns, identify root causes, and optimize workflows. Instead of treating scrap as a loss, Odoo 18 turns it into a measurable indicator of quality and operational performance. For companies using external business intelligence tools, Odoo scrap data can be exported and visualized to identify loss trends across multiple warehouses or suppliers.

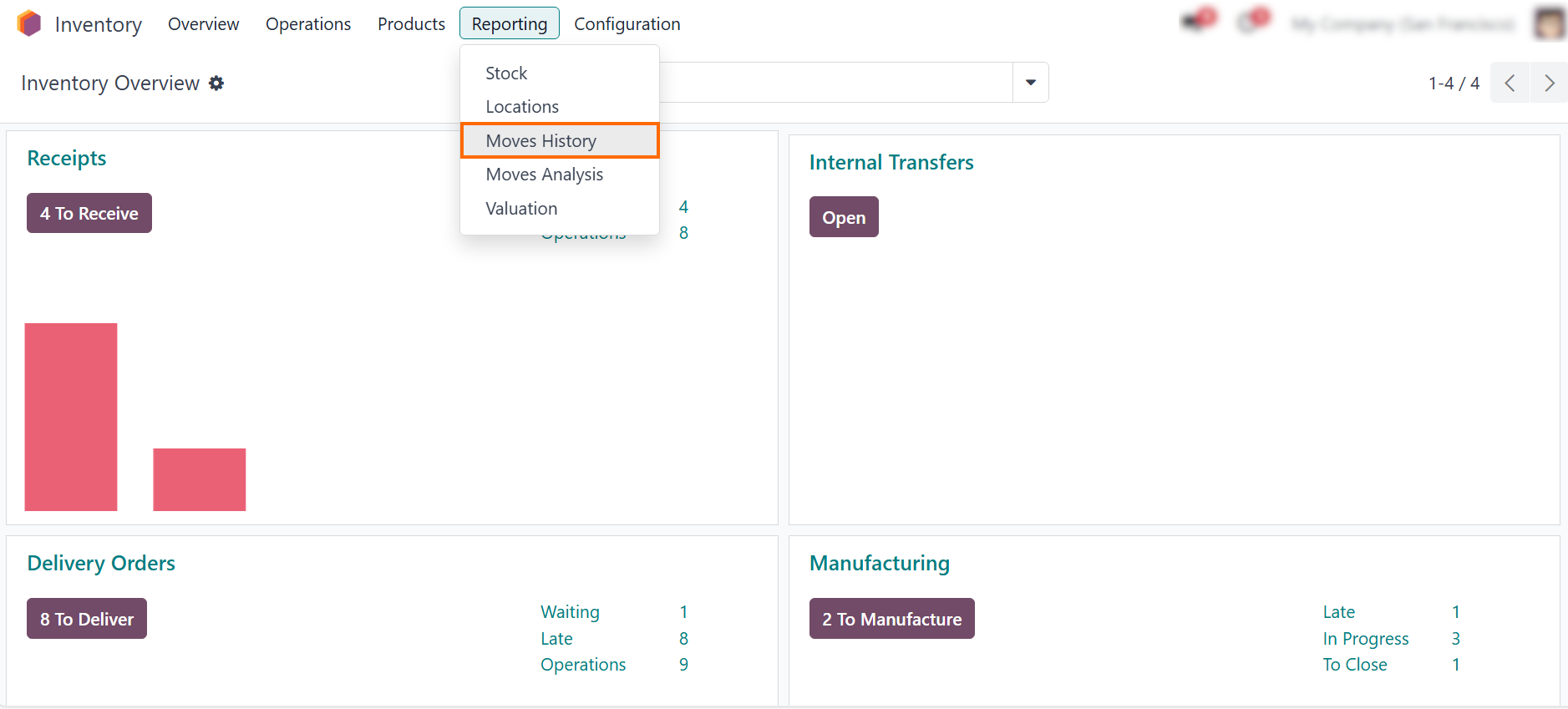

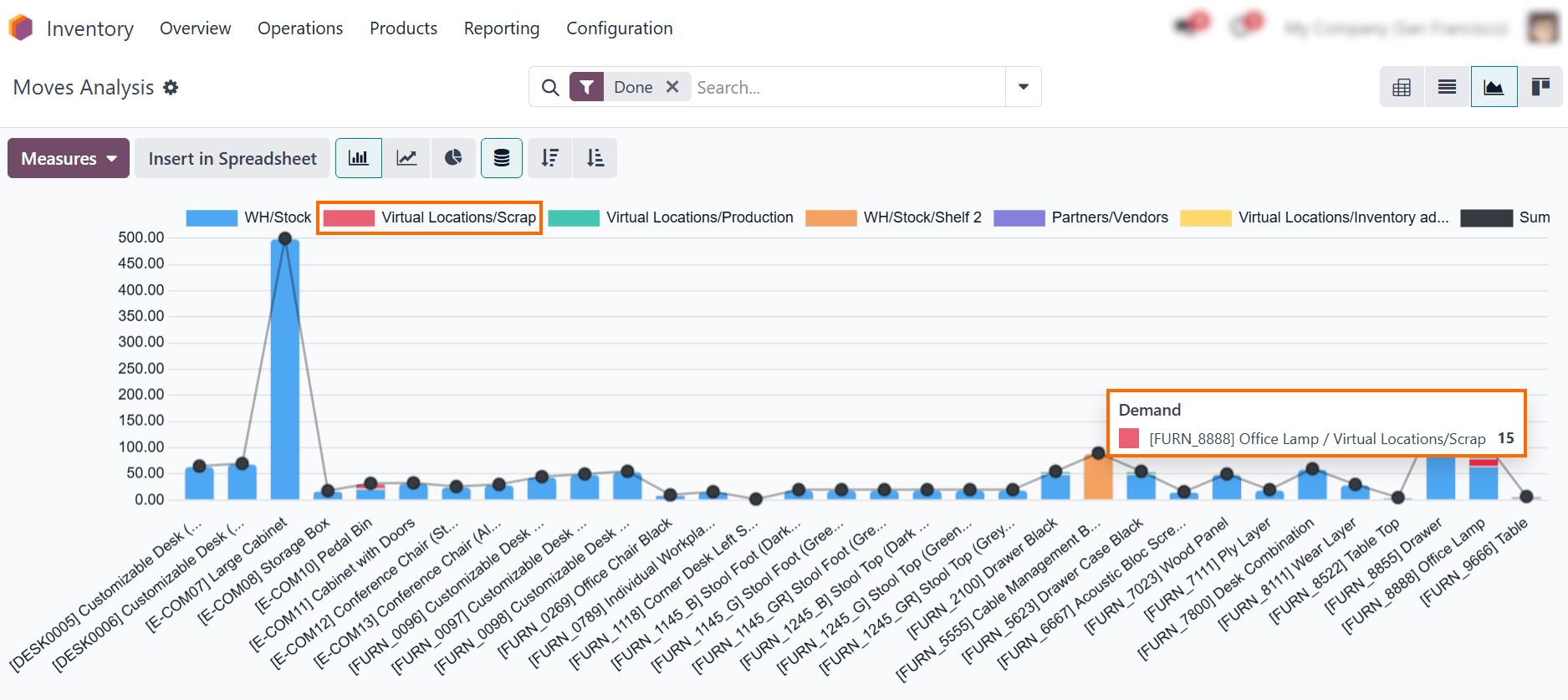

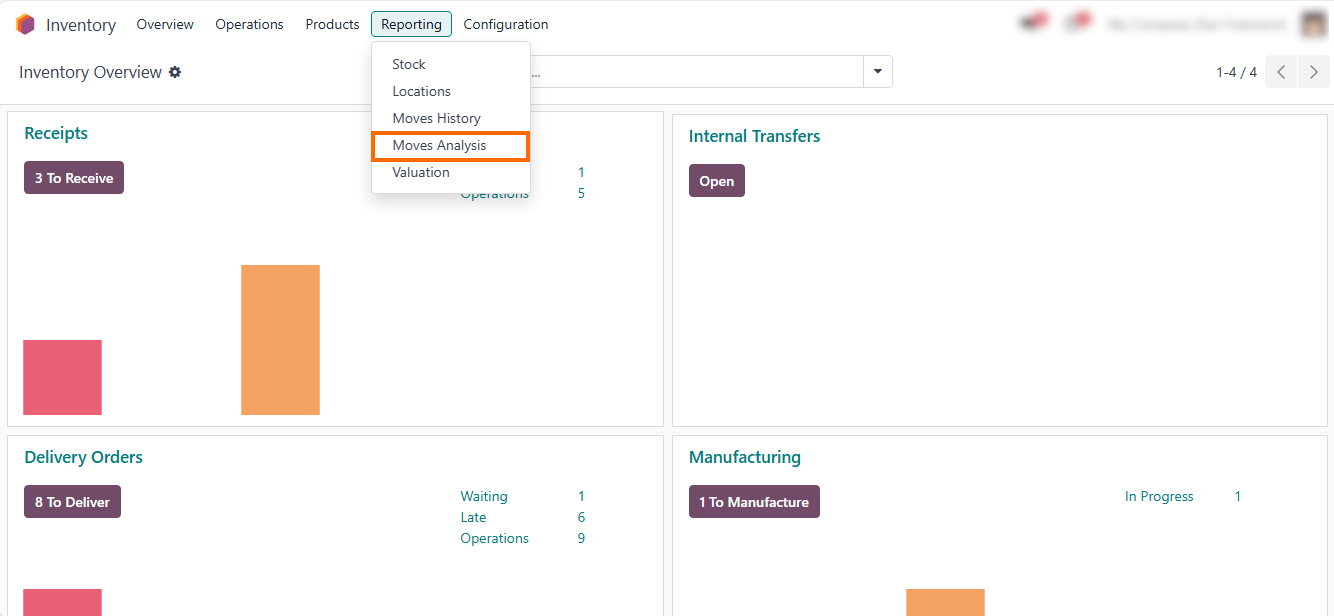

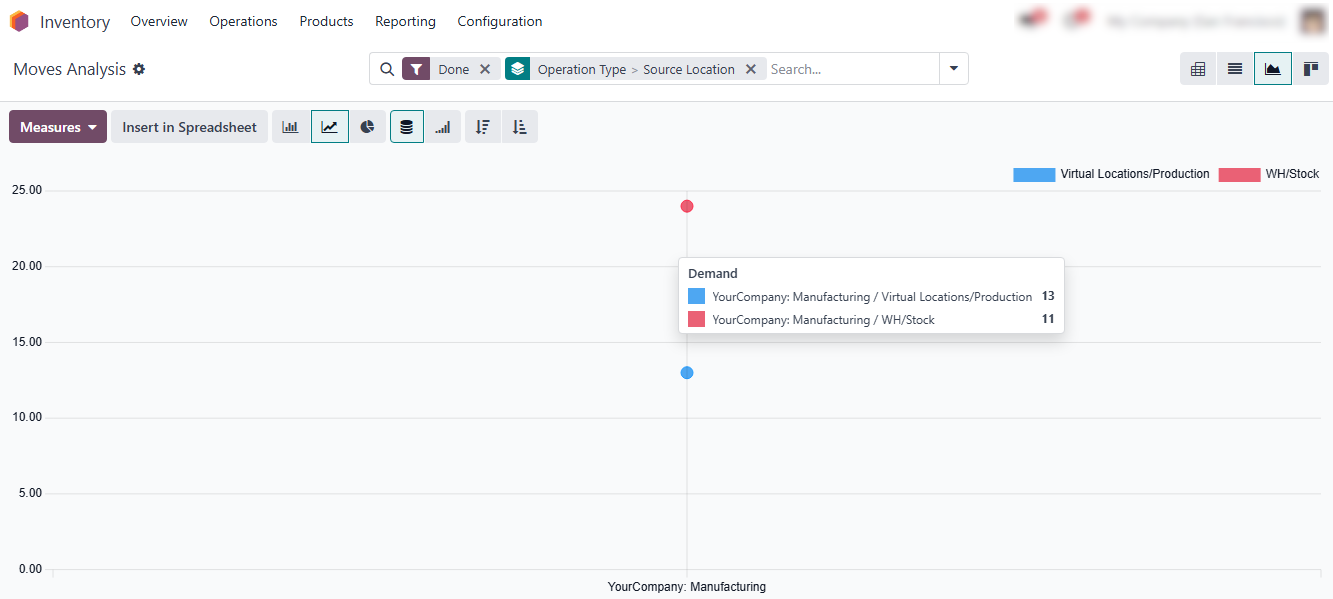

-

To access this feature, go to the "Inventory Module", at the

Reporting tab select Moves Analysis.

- Then filter by sale for scrap or another relevant filter to get a full breakdown of scrap-related activity. This report gives real-time insights into when and why scrapping inventory.

From Scrap Products for

Sale to Strategic Insight

As demonstrated in this Odoo inventory management tutorial, scrapping inventory products is no longer a standalone action – it’s a data point that can drive smarter decisions across your entire operation. By integrating Odoo scrap tracking with the reporting engine, "Inventory" and "Manufacturing" modules, and even with "Quality" and "Accounting" apps, businesses gain the power to turn isolated loss events into actionable insights. Managers can compare scrap share trends by product line, correlate failures with specific work orders, or analyze scrap value by supplier. Tracking scrap KPIs over time also reveals where inefficiencies, skill gaps, or recurring quality issues emerge. These insights allow companies to benchmark operational health, set realistic targets, and hold teams accountable using data.

- Now, select Moves Analysis from the Reporting tab in the Inventory module to access detailed sale of scrap materials data.

-

This view allows you to analyze when, where, and why scrapping inventory, helping you

make

data-backed

decisions and drive operational improvements.

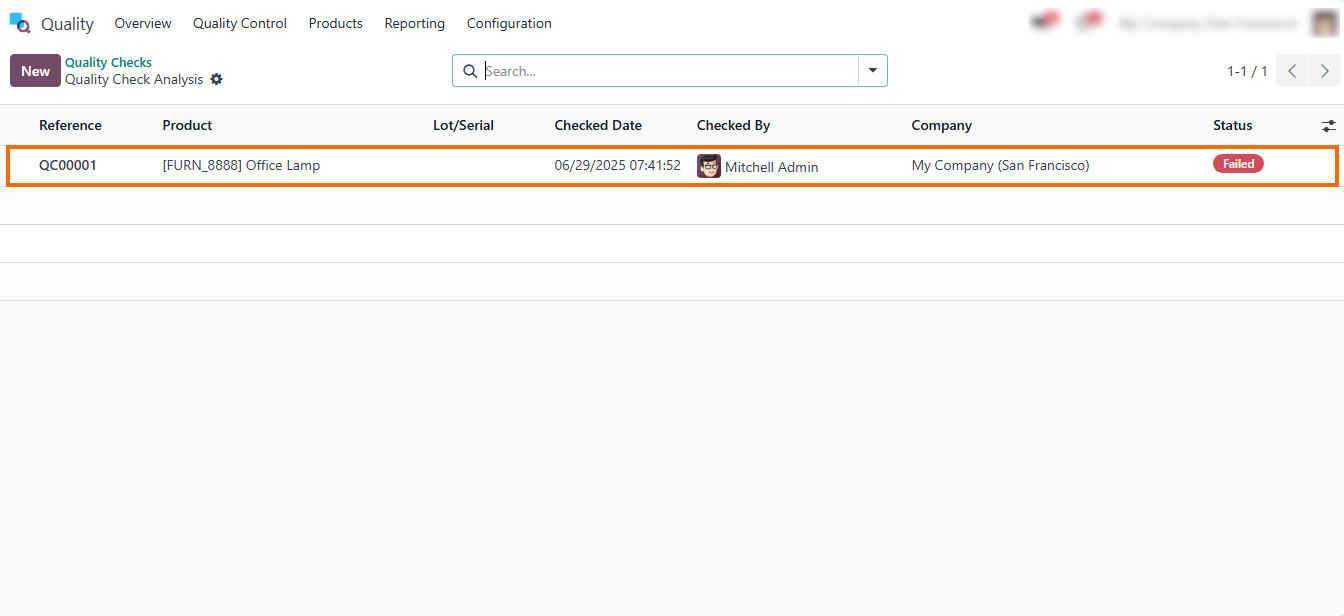

Scrap Inventory Definition with Quality Checks in Odoo 18

Across many business sectors, scrap inventory production is not just the result of a broken product it's a direct outcome of failed quality checks. That’s why Odoo forecasted inventory offers seamless integration between the "Quality" and the "Inventory" modules, allowing businesses to scrap faulty items directly from "Quality Checks" or "Quality Control Points". This is especially useful when products are rejected during incoming inspections, in-process checks, or final quality validations. The scrap sales definition right from a failed quality check ensures traceability, eliminates manual errors, and ties the loss to its root cause. For teams using the scrap inventory, this connection between inspection and scrapping reinforces accountability and drives better decision-making across procurement and manufacturing workflows.

-

This approach guarantees that the rejected items are logged properly, inventory Odoo stays accurate, and the quality check form shows a fail result.

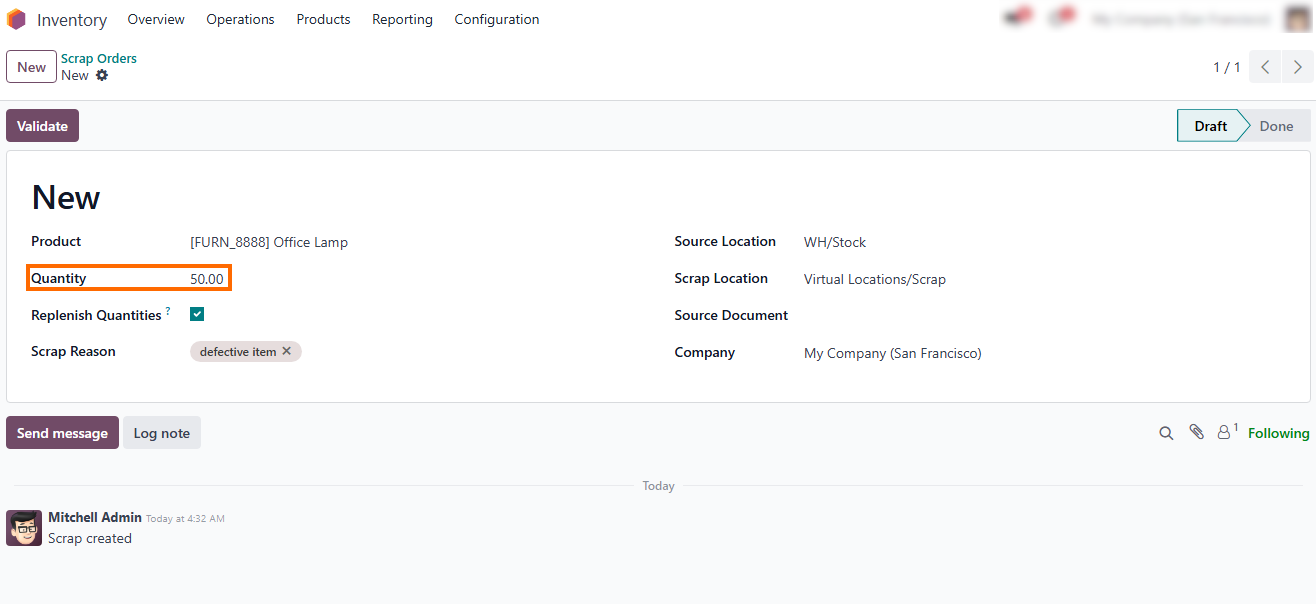

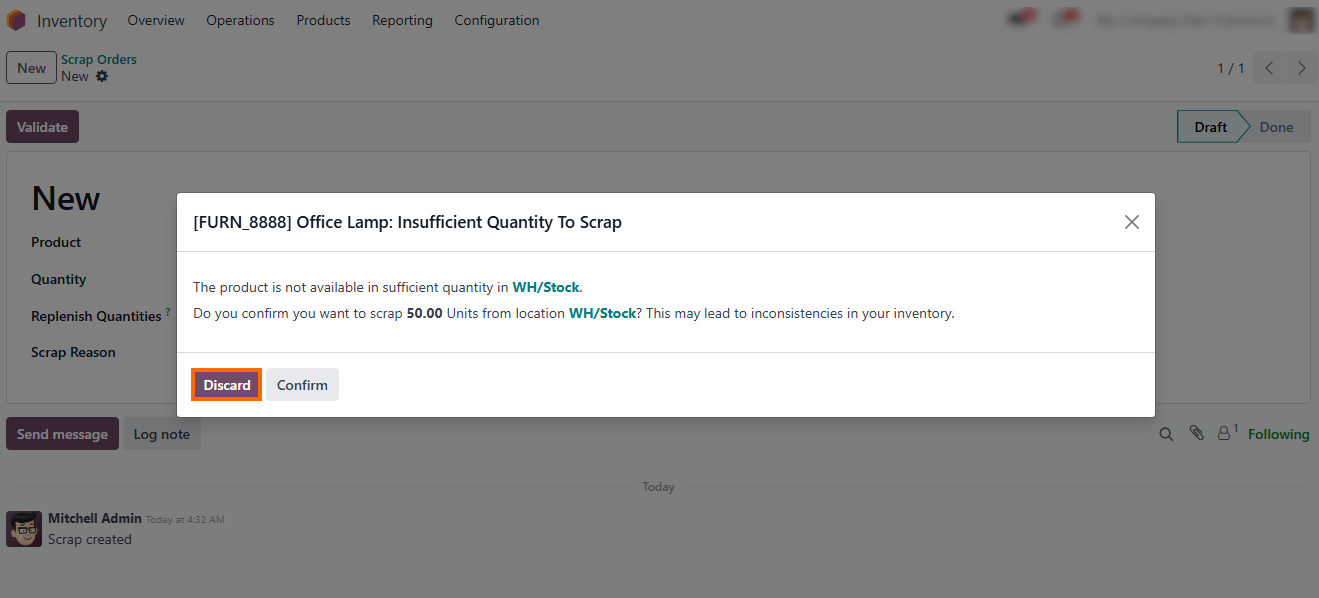

Common Scrap Sales Mistakes and How to Avoid Them

Even with a well-configured Inventory module, Odoo scrap operations can easily lead to reporting errors if performed incorrectly. Typical mistakes, such as selecting the wrong location type, skipping the Validate step, or adjusting quantities manually can break traceability, distort stock levels, and undermine costing accuracy. When users bypass the formal product scrap flow or fail to classify losses correctly, the result is unreliable data that weakens inventory Odoo control and misleads decision-makers. To maintain data integrity and ensure accurate inventory valuation, businesses must establish clear rules for scrapping, enforce proper user training, and regularly audit scrap-related records. Any error in product selection, quantity, or scrap sales location directly affects inventory analytics, costing reports, and the visibility of operational performance across warehouses.

-

Let’s simulate an incorrect sale of scrap operation by attempting to

scrap 50 units of LED

simulate an incorrect sale of scrap operation by attempting to

scrap 50 units of LED lamps, even though only 15 units are currently available

in stock.

-

This step protects against inaccurate

stock adjustments and ensures that only the correct number of faulty products is removed

from inventory.

Top Inventory Scrap KPIs to Monitor in Odoo 18

For companies using of scrap Odoo features, monitoring KPIs is essential to transform raw inventory scrap data into real-time operational insights. With the right setup of the Inventory module, managers can go far beyond simply recording losses. By integrating scrap inventory management in Odoo strategy, you ensure accurate accounting for scrap inventory, enhance traceability, and support data-driven decision-making. Whether you are tracking virtual scrap locations, monitoring scrap takeout, or analyzing scrap share across shifts, these KPIs lay the groundwork for smarter, leaner operations. As a result, these metrics also help identify systemic weaknesses across manufacturing lines, suppliers, or warehouse teams.

Scrap Rate

The Scrap Rate compares the number of scrapped units to the total number of produced, received, or processed items. This rate highlights product loss trends, supplier issues, and weaknesses in operational controls. High rates may indicate the need to update the scrap sales procedure or revise your scrap sales process across warehouse. Use this feature, as a baseline when reviewing your Odoo Inventory Report or forecasted inventory strategy.

Scrap Cost Value

This KPI tracks the total value of scrapped materials based on actual or standard cost, which feeds directly into scrap inventory accounting. It reflects how sales and scrap items for sale impact the bottom line. Accurate valuation is also crucial for scrap sales accounting and maintaining consistency across your sale of scrap materials and scrap products for sale workflows.

Scrap by Reason Categorization

Categorizing the cause of scrapped items helps you create a reliable scrap inventory definition and ensure every scrap document includes a root cause. Grouping by reason also improves Odoo inventory scrap analytics, reduces unclassified losses, and enhances stock scrap forecasting. When every document includes clear reasoning, businesses gain visibility into trends and can optimize quality control processes.

Scrap By User or Team

Understanding what is scrap object behavior per user or team helps uncover operational inconsistencies. This is especially useful when monitoring multiple sites or work shift. For example, comparing scrap items created by different teams can reveal procedural deviations. These insights are particularly powerful in organizations using Odoo inventory to train staff on standardized workflows.

Scrap Location Utilization

Measuring how often each scrap location, including virtual scrap and scrap outside the box areas – is used can uncover both bottlenecks and missed traceability. Underused locations may signal incorrect scrapping workflows, while overuse could indicate deeper quality issues. When tracked within the inventory in Odoo, this KPI also supports better routing and planning across scrap view dashboards and internal audits.

Conclusion

Efficient scrap inventory management in Odoo 18 is not just about isolating waste – it’s a strategic process that improves operational control, supports accurate stock valuation, and enhances data visibility across the entire supply chain. From defining virtual scrap locations to executing scrap actions during production and quality checks, Odoo provides an end-to-end solution that’s deeply integrated with Inventory, Manufacturing, Quality, and Accounting modules. With proper configuration, businesses can reduce errors, standardize workflows, and transform scrap events into measurable KPIs.

By using built-in analytics, structured stock scrap documentation, and clear accountability, companies can identify recurring issues, prevent waste, and support continuous improvement. Scrap is no longer a passive loss – it becomes a vital performance indicator and a foundation for better decision-making. Features like the ability to scrap all at once simplify mass product removals, and eliminate repetitive manual entries, making large-scale scrap operations faster, more reliable, and fully traceable.

As businesses scale, centralized scrap sales, real-time traceability, and reliable scrap inventory accounting become essential to stay audit-ready, meet compliance standards, and maintain profitability. As a result, once your scrap process is fully configured, Odoo scrap management becomes a strategic asset. Want to know more? Looking to optimize your scrap workflows with proven methods? Contact us for a personalized consultation – we’ll share actionable insights from real-world Odoo implementations.