Effective management of production resources is not just a technical necessity, but a true competitive advantage for any manufacturing enterprise. In today's environment, where every minute of downtime costs money and product quality directly impacts brand reputation, proper organization of work processes becomes critically important. Odoo Work Centers serve as central management hubs that help optimize production, coordinate workloads, and significantly improve your company's operational performance.

In this comprehensive guide, we'll explore all aspects of configuring, customizing, and effectively using work centers in Odoo 18 Manufacturing. You'll learn about every important parameter—from capacity planning to maintenance tracking—to achieve maximum return from your production operations.

What Are Work Centers in Odoo and Why They're Critically Important

Before diving into technical settings, it's crucial to understand the fundamental concept of work centers and their role in the production process. Many companies underestimate this tool, using only basic functions, thereby losing tremendous potential for optimization.

In the Odoo system, a work center represents a physical or logical location where specific production operations are performed. It can be a separate machine, an entire production line, or even a specialized team of workers performing certain tasks.

Each work center is characterized by its own parameters: cost per hour of operation, efficiency coefficient, work schedule, and available capacity. This data allows the Odoo system to intelligently plan tasks, calculate costs, and analyze production productivity.

Properly configured work centers provide:

- Accurate cost tracking and financial planning

- Minimized downtime through smart scheduling

- Quality performance monitoring and maintenance planning

- Complete transparency of production operations at all levels

Step 1 — Activating Work Orders in Odoo 18

The first step toward creating an effective production management system is proper preparation of the system's basic settings. Without activating the work orders feature, you won't be able to use the full potential of the manufacturing module. This stage is the foundation for all subsequent work.

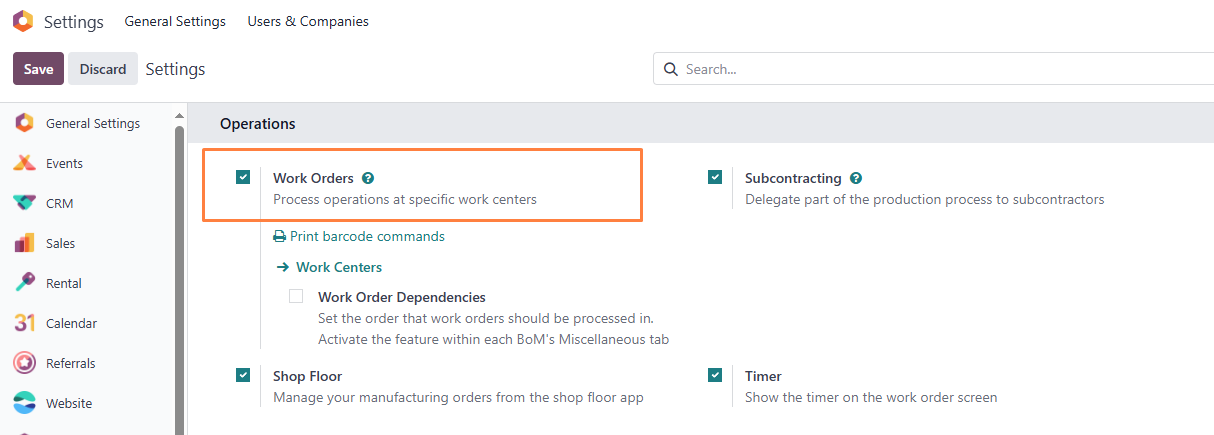

Before creating your first work center, ensure that the work orders feature is enabled in the manufacturing module settings.

Navigate to: Configuration → Settings → Work Orders → Save

Once this option is activated, Odoo will give you the ability to manage production orders step-by-step within your work centers, providing complete control over every operation on the production floor.

Step 2 — Accessing the Work Centers Dashboard

Navigation in the system is the first thing you need to master for effective work. The work centers dashboard will become your main tool for monitoring and coordinating all production processes in real-time.

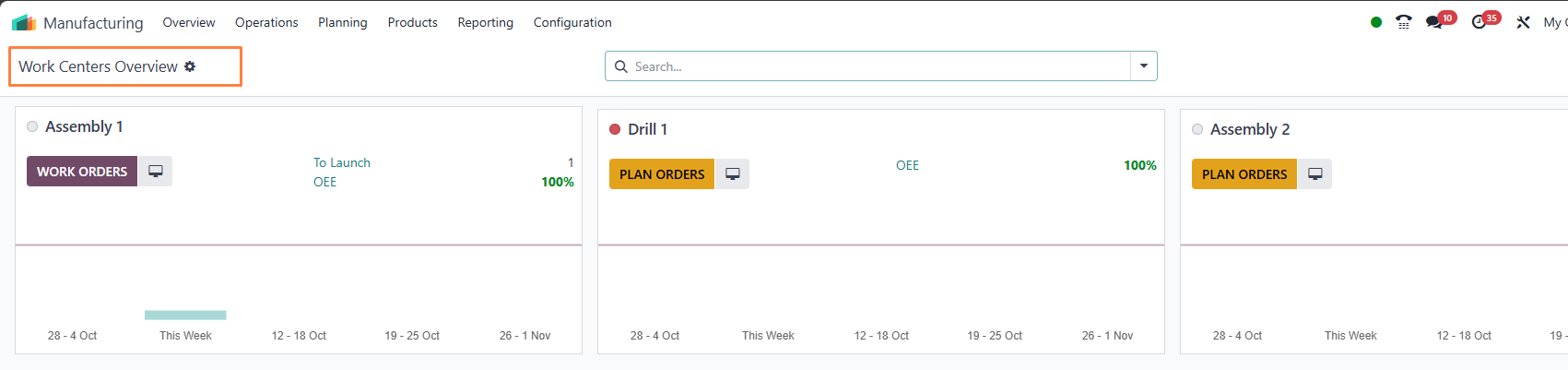

After activating work orders, open the Manufacturing module. Here you'll find the work centers dashboard, displayed in Kanban view.

This dashboard provides a quick overview of all active centers, their statuses, performance levels, and current work orders. For example, a center named Assembly 1 might show an OEE (Overall Equipment Effectiveness) rate of 100%, indicating fully optimal operation.

If a center is blocked or under maintenance, it will display with a red indicator—signaling that new operations cannot be scheduled until its reactivation.

Step 3 — Creating and Basic Configuration of a New Work Center

Creating a work center isn't just about filling out a form—it's a strategic decision that will affect your entire production structure. Every parameter you set at this stage will determine how effectively the system can plan and control operations.

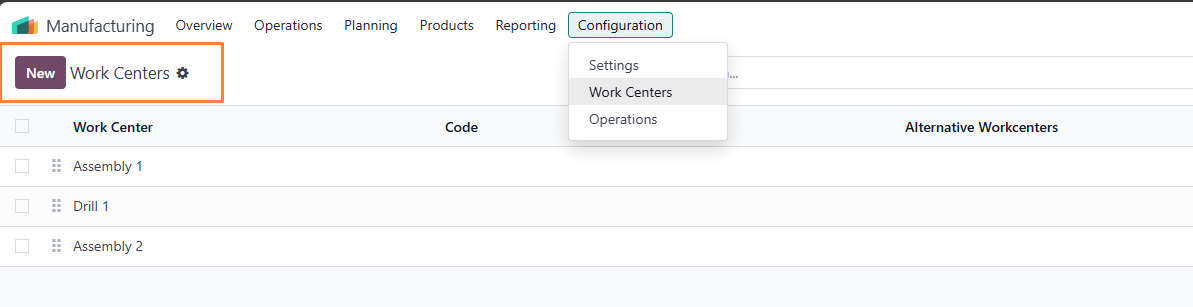

To create a new work center: Manufacturing → Configuration → Work Centers → New

In the form that opens, you'll need to fill in several key fields:

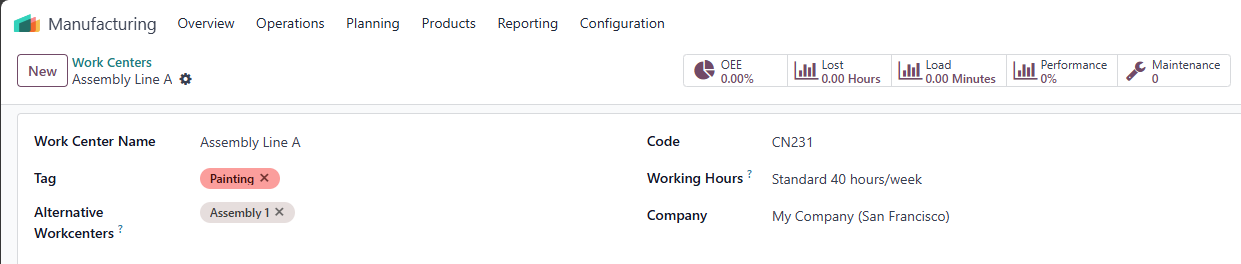

- Work Center Name: For example — "Assembly Line A"

- Code: A short identifier for quick search

- Tag: For categorizing centers (e.g., Assembly, Welding, Painting)

- Alternative Work Center: A backup location that takes over the load when the main one is overloaded or under maintenance

- Working Hours: Defining the operational time range

- Company: Associated company for multi-organizational structures

The Importance of Alternative Work Centers

Alternative work centers are particularly useful for large-scale operations. They reduce downtime and ensure continuity of production flow even when one unit is unavailable due to technical reasons or scheduled maintenance.

Step 4 — Configuring General Production Parameters

Proper parameter configuration is where technical knowledge meets business strategy. This is where you lay the foundation for accurate cost calculations, realistic planning, and objective assessment of each work center's efficiency.

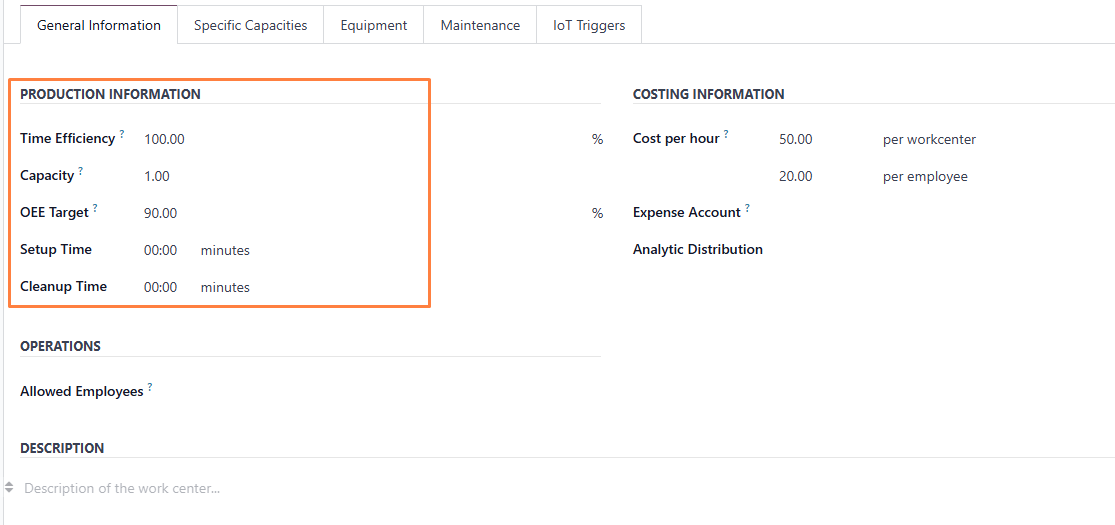

The General Information tab is divided into four sections: Production Information, Costing Information, Operations, and Description

Production Information

This section contains key performance parameters:

- Time Efficiency: Adjusts the estimated task completion time. For example, 200% efficiency cuts expected completion time in half

- OEE Target: The ideal performance ratio for a specific center

- Setup Time: Duration of equipment setup before production begins

- Cleanup Time: Time required for cleaning or resetting after each operation

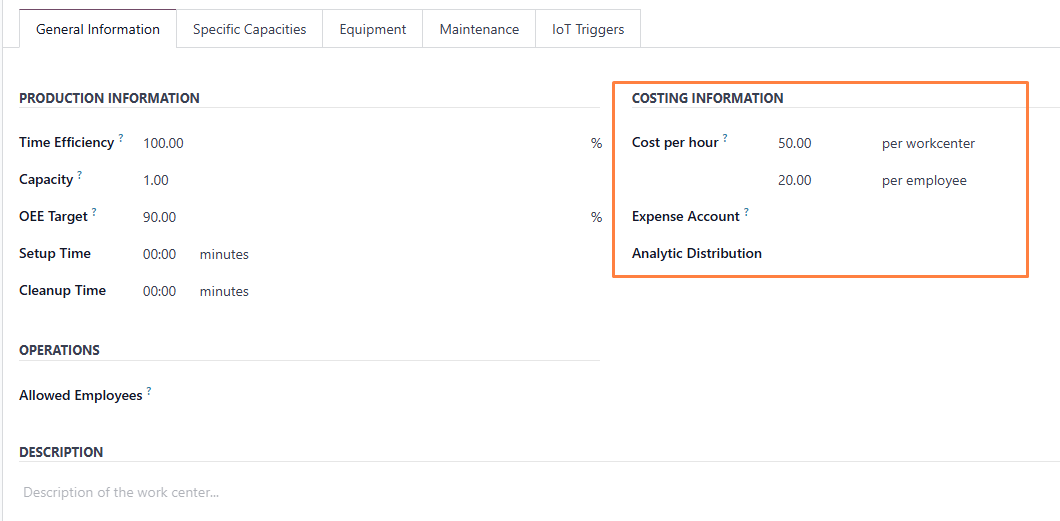

Costing Information

Here you define cost-related parameters:

- Cost per Hour: Separately for employees and for the center overall—necessary for accurate operational expense calculations

- Expense Account: Determines where cost entries will be recorded

- Analytic Distribution: Helps allocate costs across departments or projects

When a manufacturing order is completed, these costs are automatically included in the final product valuation, ensuring financial accuracy in Odoo.

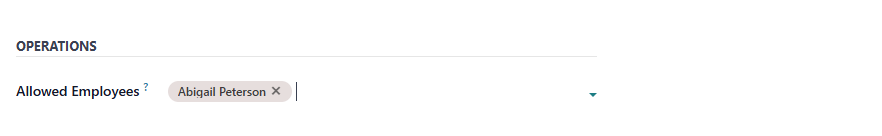

Step 5 — Managing Operations and Access Rights

Security and access control aren't paranoia—they're necessary elements of professional production organization. Proper access rights configuration helps avoid errors, unauthorized changes, and ensures each employee's accountability for their work area.

In the Operations section, specify which employees have the right to log in and perform actions in this work center. If you leave the field empty, any manufacturing employee will have access.

In the Description field, you can add internal notes—for example, specific operating instructions or maintenance reminders for operators.

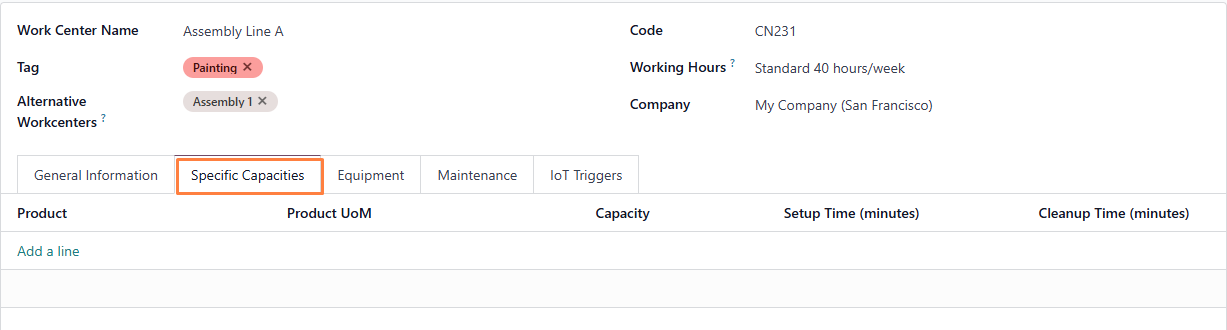

Step 6 — Configuring Specific Capacities for Different Products

Flexibility in planning is what distinguishes a good management system from an excellent one. Different products often require different production approaches, and the system must account for this to achieve maximum efficiency.

Sometimes different products require different production capacities. In the Specific Capacities tab, you can define individual capacity parameters for each product separately.

By clicking "Add a line", you can include:

- Product name

- Production capacity

- Setup and cleanup time for the specific item

This flexibility ensures more accurate scheduling and helps balance workload across your work centers.

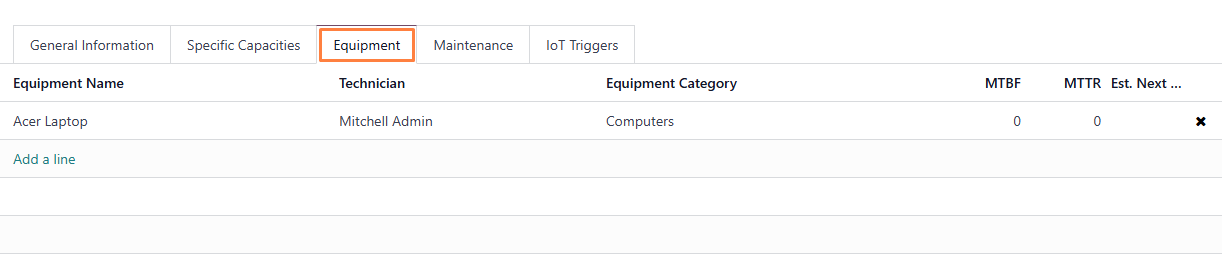

Step 7 — Linking Equipment to Work Centers

Modern production is impossible without specialized equipment, and its effective use requires a systematic approach to accounting and maintenance. Integrating equipment with work centers provides a complete picture of production capabilities and potential bottlenecks.

When certain machines or tools are critical to a process, they can be attached to the work center through the Equipment tab.

Each item includes fields:

- Equipment name

- Responsible technician

- Equipment capacity

- MTBF (Mean Time Between Failures)

- MTTR (Mean Time To Repair)

This ensures all related machinery is properly tracked and maintained within the system.

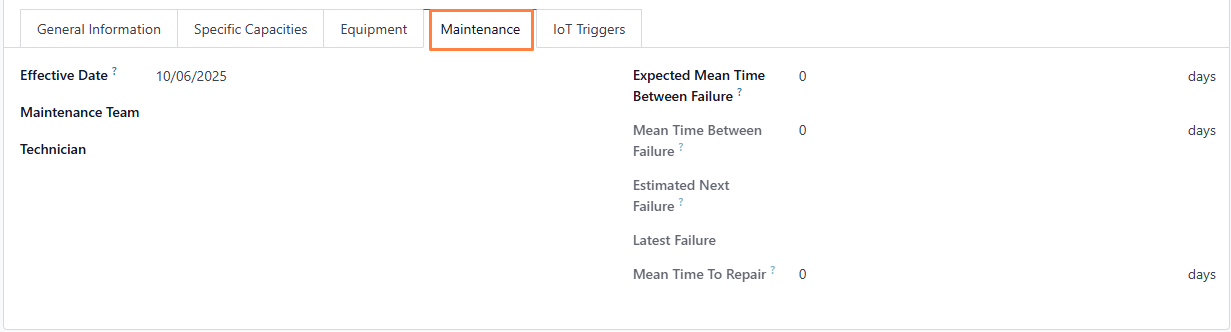

Step 8 — Configuring Maintenance and Reliability

Prevention is always cheaper than repair—this axiom is especially relevant in manufacturing. A systematic approach to maintenance not only extends equipment service life but also allows for budget planning for repairs and avoids unexpected downtime.

The Maintenance tab helps monitor the long-term health of each work center.

Here you can define:

- Effective Date: When the work center became active

- Maintenance Team and Technician: Who is responsible for upkeep

- Expected MTBF: Predicted time interval between two failures

Odoo automatically updates MTBF and MTTR values based on maintenance records, helping you predict future breakdowns and efficiently schedule preventive repairs.

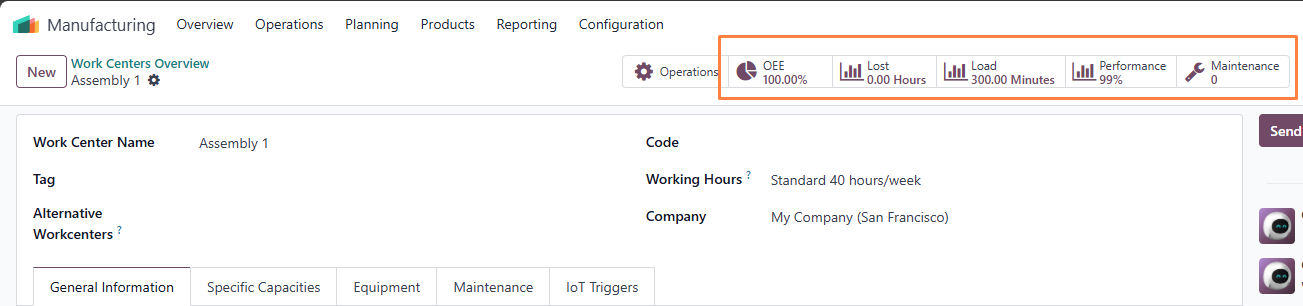

Step 9 — Using Smart Tabs for Performance Analysis

Data without analysis is just numbers on a screen. The real value of a production management system lies in its ability to transform raw data into understandable insights that help make the right management decisions quickly and confidently.

The Odoo work center form includes several Smart Tabs that provide deep insights into performance:

Main Analytics Tabs

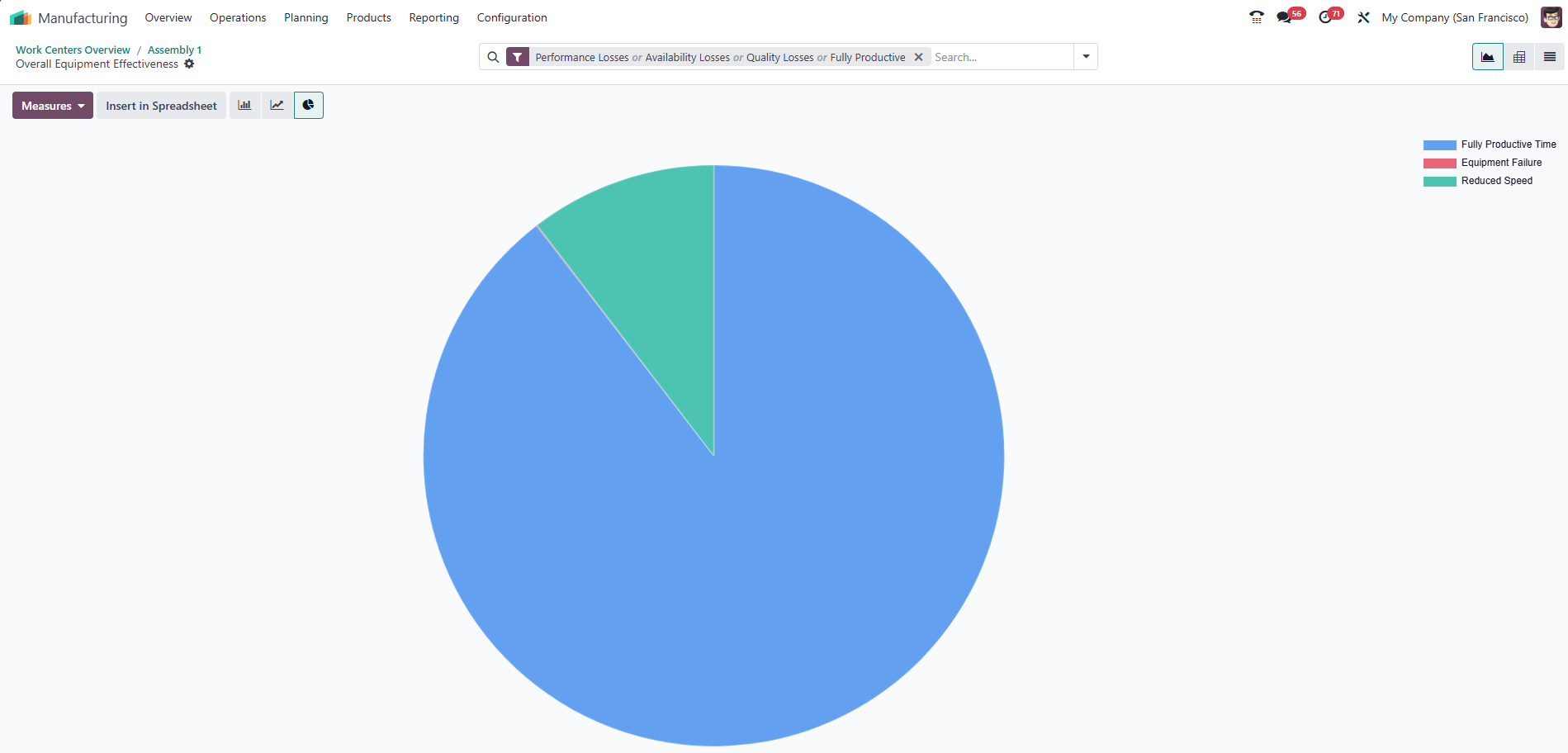

- OEE (Overall Equipment Effectiveness): Shows how efficiently the center operates by analyzing time, losses, and productivity

- Lost: Displays all productivity losses due to machine failures, speed reduction, or other factors. You can create new loss entries manually for better tracking

- Load: Provides a real-time overview of all scheduled work orders and their expected time loads

- Performance: Detailed report on completed work orders, production duration, and cost per operation

- Maintenance:List of all maintenance requests linked to the selected work center, with the ability to create new ones

These tools give managers complete control and visibility over production performance.

Step 10 — Monitoring and Continuous Improvement

System configuration isn't an endpoint—it's the beginning of the journey toward operational excellence. Real results come when you regularly analyze data, identify weaknesses, and implement improvements based on objective information.

After completing all configurations, the work centers dashboard becomes your control panel for monitoring efficiency. You can track real-time metrics: workload, downtime, and OEE indicators.

If a center shows low productivity, Odoo's reporting tools help identify bottlenecks and optimize processes—for example, through rescheduling operations or assigning them to alternative centers.

By regularly reviewing performance reports and updating configurations, manufacturers can ensure that each work center effectively contributes to the enterprise's overall productivity.

Conclusion: Your Path to Manufacturing Excellence

Setting up Odoo work centers isn't just a technical task of defining locations or equipment. It's creating a structured, data-driven manufacturing system that works like clockwork.

By managing capacities, costs, and productivity in Odoo, businesses can significantly reduce inefficiencies, maintain quality standards, and increase overall production volume.

Whether you manage a small workshop or a large-scale plant, proper configuration of work centers in Odoo 18 will help achieve greater control, transparency, and profitability in the production process. The time investment in configuration today will pay off many times over through increased efficiency tomorrow.