Subcontracting is a strategic approach where a company delegates specific production tasks or service operations to an external vendor rather than managing them in-house. This practice is widely adopted in manufacturing, construction, and service industries, particularly when specialized expertise, cost efficiency, or increased production capacity is required. By leveraging subcontracting, businesses can streamline operations, reduce capital investment, and access advanced skills without maintaining an extensive in-house workforce. It enables companies to focus on their core competencies while ensuring high-quality output from external partners who specialize in particular aspects of the production process.

Key Aspects of Subcontracting

- Delegation of Production Tasks – Instead of handling every stage of manufacturing in-house, companies assign specific tasks to a subcontract manufacturer who specializes in that process. This ensures higher efficiency and better quality control.

- Optimized Resource Utilization – By subcontracting, businesses can lower operational costs, reduce the need for heavy capital investment, and enhance productivity by focusing on their core competencies while leveraging external expertise.

- Supply Chain & Inventory Coordination – Effective subcontracting production strategy requires precise tracking of raw materials supplied to subcontractors and finished goods received. Proper inventory management ensures seamless operations and avoids material shortages or excess stock.

Subcontracting in Manufacturing

In modern manufacturing, businesses often rely on subcontracting production to enhance efficiency and reduce costs. This approach involves delegating specific stages of production to a subcontract manufacturer, allowing companies to focus on core operations while benefiting from specialized expertise. Unlike handling all processes in-house, manufacturing subcontracting enables access to advanced technology, skilled labor, and increased production capacity without requiring significant capital investment. Industries such as automotive, electronics, and metal fabrication frequently adopt this strategy to improve productivity and maintain high-quality standards while optimizing resources.

Difference Between Subcontracting and Outsourcing

Although subcontracting and outsourcing both involve working with external partners, they differ in terms of scope, control, and strategic intent. Businesses must carefully evaluate which approach aligns best with their operational needs.

Subcontracting Production –

Focused Task Delegation with Controlled Oversight

Subcontracting production is a structured collaboration where a company assigns a specific production task to a manufacturing subcontractor, while still maintaining control over the final product quality, production standards, and supply chain management. Unlike outsourcing, where entire processes are transferred to external providers, subcontracting ensures that the company retains decision-making authority over the broader manufacturing strategy.

- Example 1: Subcontracting in the Automotive Industry

SpeedTech Motors, an electric vehicle manufacturer, designs and assembles its vehicles in-house. However, the company subcontracts manufacturing of its battery packs to a specialized subcontract manufacturer that has the necessary technology and expertise to build high-performance lithium-ion batteries. Although SpeedTech does not produce the batteries themselves, they oversee the design specifications, quality control, and integration of the batteries into their vehicles, ensuring they meet industry standards.

- Example 2: Subcontracting in Electronics Manufacturing

NeoGadgets, a consumer electronics brand, produces smart home devices. While their in-house team focuses on product design and software development, they subcontract production of plastic casings and circuit board assembly to external manufacturers. These subcontractors complete the specific components, but NeoGadgets retains full control over product assembly, testing, and final packaging before releasing devices to the market.

- Example 3: Subcontracting in Apparel Manufacturing

Elite Fashion Co., a high-end clothing brand, manages fabric selection, pattern design, and marketing in-house. However, the company subcontracts garment stitching and embroidery to specialized fabrication subcontract work vendors who have expertise in fine detailing. Even though external vendors handle the sewing process, Elite Fashion retains full control over the quality standards, design elements, and final product presentation.

Outsourcing

– Full Process or Department Transfer with Minimal Oversight

Unlike subcontracting, outsourcing involves transferring an entire business function or operational process to an external provider. In this case, the hiring company does not directly control the execution of tasks but instead relies on the service provider to handle operations independently.

- Example 1: Outsourcing Customer Support

TechNova Solutions, a software company, does not maintain an in-house customer service team. Instead, they outsource their customer support operations to a third-party call center that handles technical inquiries and troubleshooting on their behalf. While TechNova sets general guidelines and service expectations, the outsourced provider manages the team, response protocols, and day-to-day operations.

- Example 2: Outsourcing IT Management

Skyline Retail Group, an international retail chain, outsources its IT infrastructure management to an external cloud service provider. This partner is responsible for server maintenance, cybersecurity, and software updates, ensuring smooth IT operations while Skyline focuses on retail expansion.

- Example 3: Outsourcing Human Resources

GlobalMed Pharmaceuticals decides to outsource HR and payroll management to a professional employer organization (PEO). This external firm handles recruitment, payroll processing, employee benefits, and compliance, reducing the administrative burden on GlobalMed’s in-house team.

Key Takeaways: Subcontracting vs. Outsourcing

- Subcontracting allows a company to delegate specific production tasks to an external partner while maintaining control over product quality, supply chain, and final assembly.

- Outsourcing shifts entire business functions or departments to external providers with minimal direct involvement from the hiring company.

How Subcontracting Works in Odoo

Odoo provides a comprehensive subcontracting production strategy that enables manufacturers to efficiently manage external production, ensuring transparency, cost control, and streamlined inventory tracking. Through Odoo’s subcontracting features, companies can define subcontracting workflows, track materials sent to subcontractors, and oversee the receipt of finished goods. Below is a detailed breakdown of how subcontracting in Odoo is configured and managed:

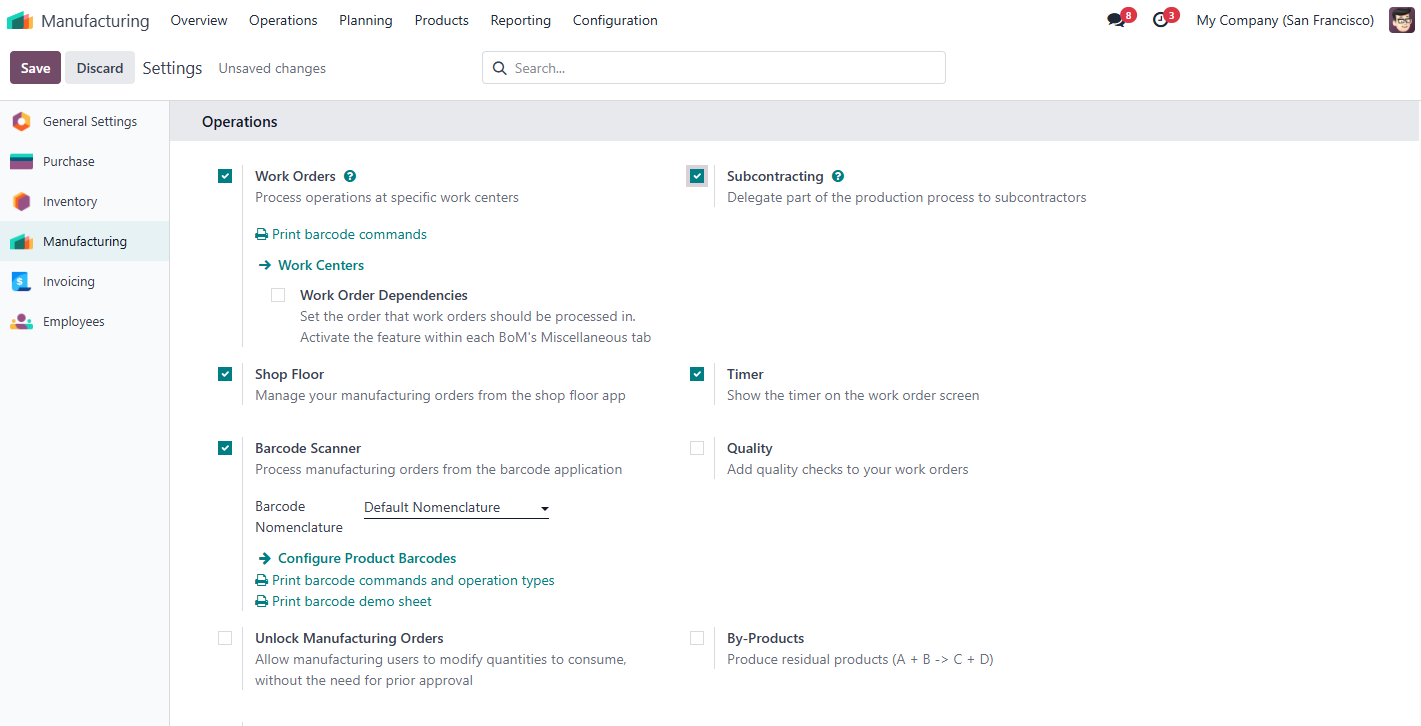

- To enable subcontracting in Odoo 18, go to Manufacturing → Configuration → Settings, scroll to the Operations section, activate the "Subcontracting" option, and click Save.

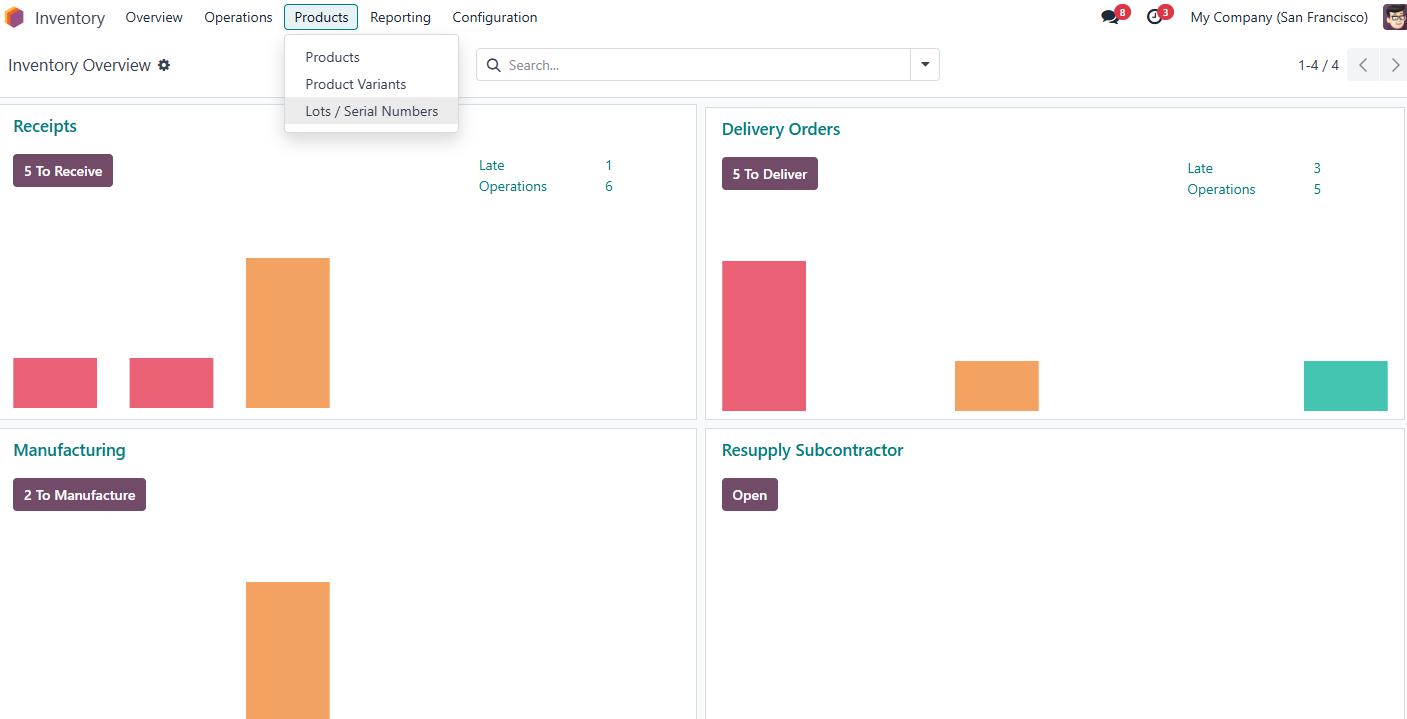

- To configure a product for subcontracting in Odoo 18, go to Inventory → Products → Products.

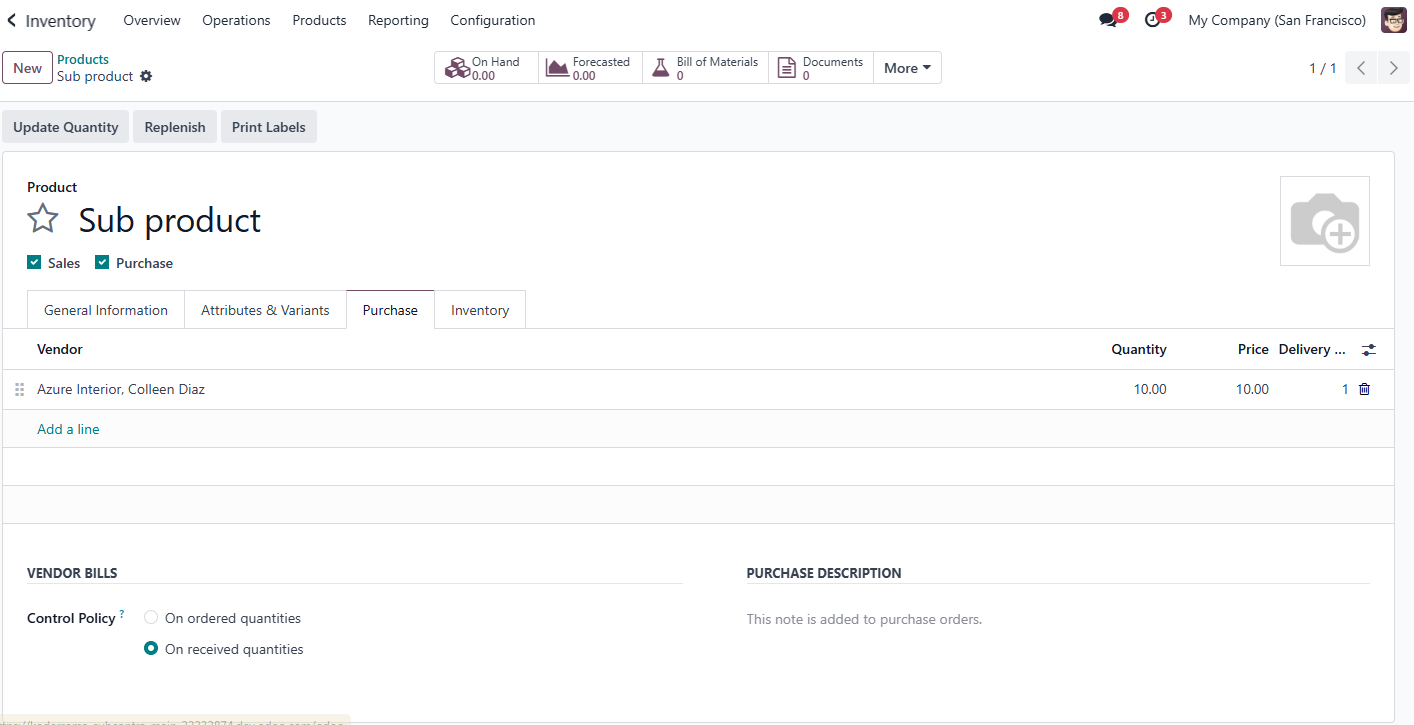

- Choose or create a product, and under the Purchase tab, add the subcontractor as a vendor with the appropriate price and lead time.

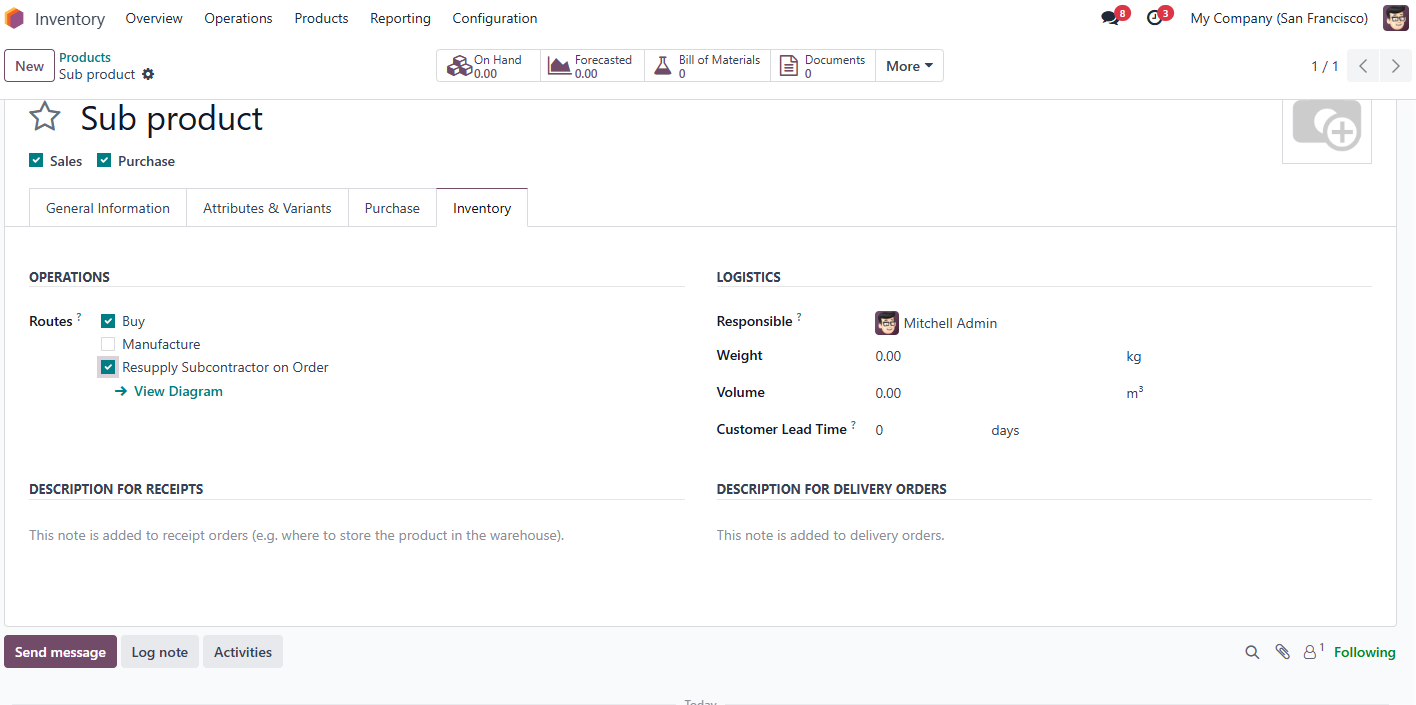

- Under the Inventory tab, enable the Buy route and optionally the Resupply Subcontractor on Order option to send components to the subcontractor when needed.

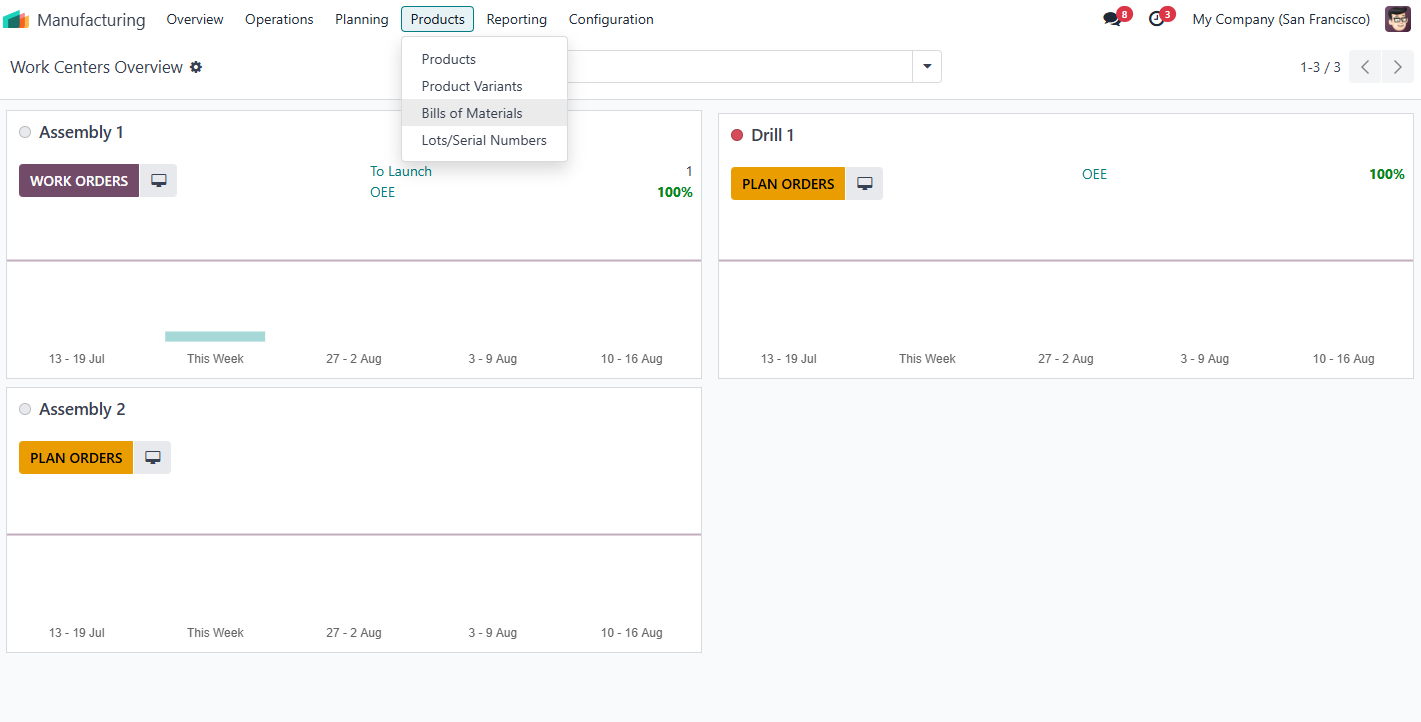

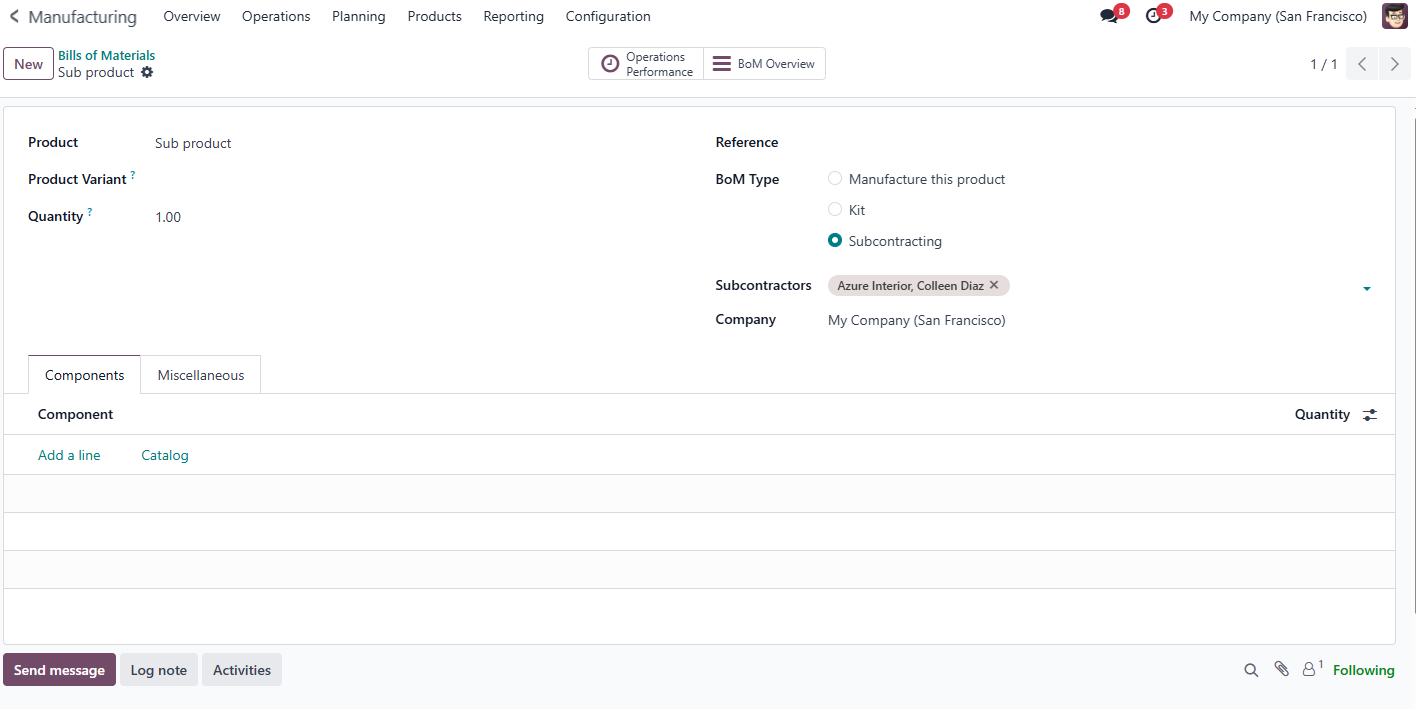

- Creating a Bill of Materials (BoM):Go to Manufacturing → Products → Bills of Materials.

- Than click Create, select the Product, choose Subcontracting in the BoM Type field, and add the subcontractor in the Subcontractors field.

Once saved, this BoM tells Odoo that the selected product will be manufactured by an external subcontractor.

From this point forward:

- When you create a Manufacturing Order for this product,

- Odoo will automatically generate a Purchase Order to the subcontractor.

- If components are defined, it will also generate a Delivery Order to ship the components.

- The subcontractor will manufacture the product and return the finished goods.

- You will then confirm receipt of the product through the Purchase Order process.

This completes the subcontracting setup and flow in Odoo 18.

How is Scrap Accounted for in Subcontracting?

In subcontract manufacturing, managing scrap is essential for accurate inventory and cost control. Within Odoo, scrap generated during subcontracting is handled through specific workflows to ensure precise accounting.

Recording Scrap in Odoo:

1. Scrap During Receipt:

- When receiving finished goods from a subcontractor, if any items are damaged or defective, you can record them as scrap directly from the receipt.

- Navigate to the specific receipt in the Inventory module, and use the "Scrap" button to move the unusable items to a designated scrap location.

2. Scrap During Delivery:

- If products are identified as scrap during the delivery process, Odoo allows for their removal from inventory at this stage.

- Access the delivery order, and utilize the "Scrap" function to account for any defective items before they reach the customer.

3. Scrap from Internal Transfers:

- In cases where products become unsellable during internal movements, you can record scrap during internal transfers.

- Within the internal transfer document, select the "Scrap" option to adjust inventory levels accordingly.

Accounting for Scrap:

1. Inventory Valuation:

- Scrapped items are moved to a virtual scrap location, effectively removing them from available stock and inventory valuation.

- This ensures that financial records accurately reflect only sellable inventory.

2. Cost Implications:

- The cost of scrapped items can be treated as a normal production loss, absorbed into the overall manufacturing expenses.

- Alternatively, if the subcontractor is responsible for the scrap due to contractual agreements, the cost may be assigned to them, affecting their billing.

By effectively managing scrap through these methods, businesses can maintain accurate inventory records and ensure that financial statements reflect true production costs. Odoo's comprehensive features facilitate this process, allowing for seamless tracking and accounting of scrapped materials.

Advantages of Subcontracting in Odoo for Efficient Manufacturing Management

Implementing subcontract manufacturing in Odoo provides significant advantages to businesses looking to streamline production, reduce costs, and enhance operational efficiency. Below are some of the key benefits along with real-world applications:

Cost Efficiency – Lower Production Costs & Capital Investment

Companies that engage in manufacturing subcontracting reduce the need for expensive in-house machinery, specialized labor, and facility expansion. By outsourcing certain production tasks, businesses optimize expenses while maintaining high product quality.

Example: AutoTech Motors, a well-established automobile manufacturer, was facing rising production costs due to the high expense of setting up an upholstery department for car seat production. To maintain profitability, they decided to subcontract manufacturing to a specialized subcontractor. The vendor handled seat production efficiently, allowing AutoTech to save on equipment costs, labor salaries, and maintenance. The cost savings enabled them to invest in R&D for better vehicle features while keeping their overall production expenses lower.

Scalability – Expanding Manufacturing Capacity Without Infrastructure Growth

When demand for a product spikes, businesses may struggle with production limitations. Subcontracting production helps companies scale quickly by utilizing external vendors without requiring additional facilities or workforce expansion.

Example: ElectroGizmo, a fast-growing consumer electronics company, experienced a surge in demand for its new smartwatch series. However, their internal production line lacked the capacity to fulfill orders on time. Instead of delaying shipments or investing in costly factory expansion, they decided to subcontract production of smartwatch circuit boards to a manufacturing subcontractor specializing in high-precision electronic components. As a result, ElectroGizmo was able to meet the growing demand while maintaining delivery schedules without overloading its internal operations.

Inventory Optimization – Better Material Flow & Stock Control

One of the challenges of subcontract manufacturing is keeping track of raw materials and finished products sent to and received from subcontractors. Odoo’s subcontracting module enables businesses to efficiently manage inventory movements, reducing errors and preventing material shortages.

Example: SteelWorks Ltd., a metal fabrication enterprise, frequently outsources the cutting and shaping of steel sheets to specialized fabrication subcontract work providers. Using Odoo’s subcontracting features, they accurately track every batch of steel sent to subcontractors and monitor the receipt of finished casings. The system ensures real-time updates on stock levels, eliminating discrepancies, preventing overstocking, and minimizing waste.

Improved Accounting & Automated Financial Management

Tracking subcontract accounting manually can lead to invoicing errors, miscalculations, and payment delays. With Odoo’s automated subcontract accounting, businesses can streamline vendor payments, track production costs accurately, and manage procurement seamlessly.

Example: FashionFit Apparel, a clothing manufacturer, partners with multiple small-scale subcontractors to handle garment stitching. Instead of manually tracking each vendor’s work and issuing invoices separately, they leverage Odoo’s subcontract accounting automation. The system records vendor billing, labor expenses, and procurement details, reducing financial errors and ensuring timely payments. This efficiency allows FashionFit to maintain good vendor relationships while optimizing overall production costs.

Maximizing Manufacturing Subcontracting with Odoo

By utilizing subcontract manufacturing within Odoo, businesses can achieve higher efficiency, better cost control, and improved production scalability. The ability to track inventory, manage subcontractor relationships, and automate accounting processes ensures smooth operations without unnecessary overhead. Whether a company requires fabrication subcontract work, large-scale subcontracting production, or tailored subcontracting production strategy, Odoo provides the tools to support business growth while maintaining full operational control.

For organizations seeking expert assistance in setting up subcontracting in Odoo, Kodershop specializes in Odoo implementations, ensuring businesses can fully leverage the platform’s features to optimize their manufacturing subcontracting processes.

Conclusion: The Future of Industrial Subcontracting with Odoo and Kodershop

In today’s highly competitive industrial environment, manufacturing subcontracting has evolved from a cost-saving measure into a strategic necessity. Companies across various industries, including automotive, electronics, and metal fabrication, increasingly rely on subcontract manufacturing to optimize efficiency, reduce overhead costs, and enhance production scalability. By outsourcing specialized tasks to subcontract manufacturers, businesses gain access to advanced expertise, cutting-edge technology, and flexible production capacities—all without requiring significant capital investment in infrastructure or additional labor.

However, managing subcontracting production efficiently requires a robust and well-structured system. This is where Odoo’s subcontracting production strategy provides a game-changing solution. With Odoo’s powerful subcontracting features, companies can track vendor relationships, monitor material flow, streamline procurement, and maintain full financial oversight—ensuring that every aspect of the subcontracting production strategy remains transparent, controlled, and aligned with business goals.

At Kodershop, we specialize in implementing, customizing, and optimizing subcontracting in Odoo to meet the unique operational needs of businesses. Our expertise spans across fabrication subcontract work, subcontract production planning, and subcontract accounting automation, ensuring that our clients have the tools they need for seamless operations. Whether a company is looking to improve its subcontractor management, automate procurement processes, or integrate a scalable subcontracting model, our team provides tailored solutions that drive productivity and long-term growth.

With Kodershop’s Odoo expertise, businesses can maximize the benefits of manufacturing subcontracting, achieve greater production agility, and stay ahead of industry trends. Whether you're a growing manufacturer looking for efficient subcontracting solutions or an established enterprise aiming to streamline subcontracting workflows, our team is ready to help you build a sustainable, cost-effective, and future-ready production model.