As businesses strive to meet customer demand while minimizing operational costs, stock replenishment emerges as a vital process that ensures the right products are available at the right time. From retail to manufacturing, an efficient replenishment products strategy can make or break supply chain performance. The importance of inventory replenishment cannot be overstated, as it plays a pivotal role in preventing inventory shortages, optimizing warehouse operations, and supporting seamless order fulfillment across the supply chain. This importance has only grown in recent years, especially amid global supply chain disruptions, labor shortages, and rising customer expectations for rapid delivery. As a result, replenishment has become a strategic priority.

So, businesses that invest in intelligent order replenishment systems gain a competitive edge by ensuring product availability, improving customer satisfaction, and optimizing resource allocation across warehouses and distribution channels. However, having the right tools is just as crucial as recognizing the need. With the right guidance and a clear understanding of Odoo MRP documentation, your replenishment system can become a true driver of operational clarity, cost control, and customer satisfaction. A well-tuned replenishment system reduces stress and uncertainty in operations. This guide helps businesses replenish the stock efficiently, automatically, and intelligently.

What’s New in Replenishment Functionality in Odoo 18

Effective inventory replenishment strategies enable businesses to balance demand and supply with greater accuracy, reduce excess stock, and minimize holding costs. By leveraging automated replenishment systems and real-time inventory tracking, companies can make data-driven decisions that enhance agility, reduce lead times, and improve service levels — ultimately transforming replenishment from a reactive task into a proactive supply chain advantage. The new system introduces powerful enhancements to its replenishment functionality, offering smarter planning, smoother workflows, and deeper integration with procurement and forecasting modules. Let’s explore the key improvements that redefine Odoo replenishment.

A Redesigned, Actionable

Replenishment Dashboard

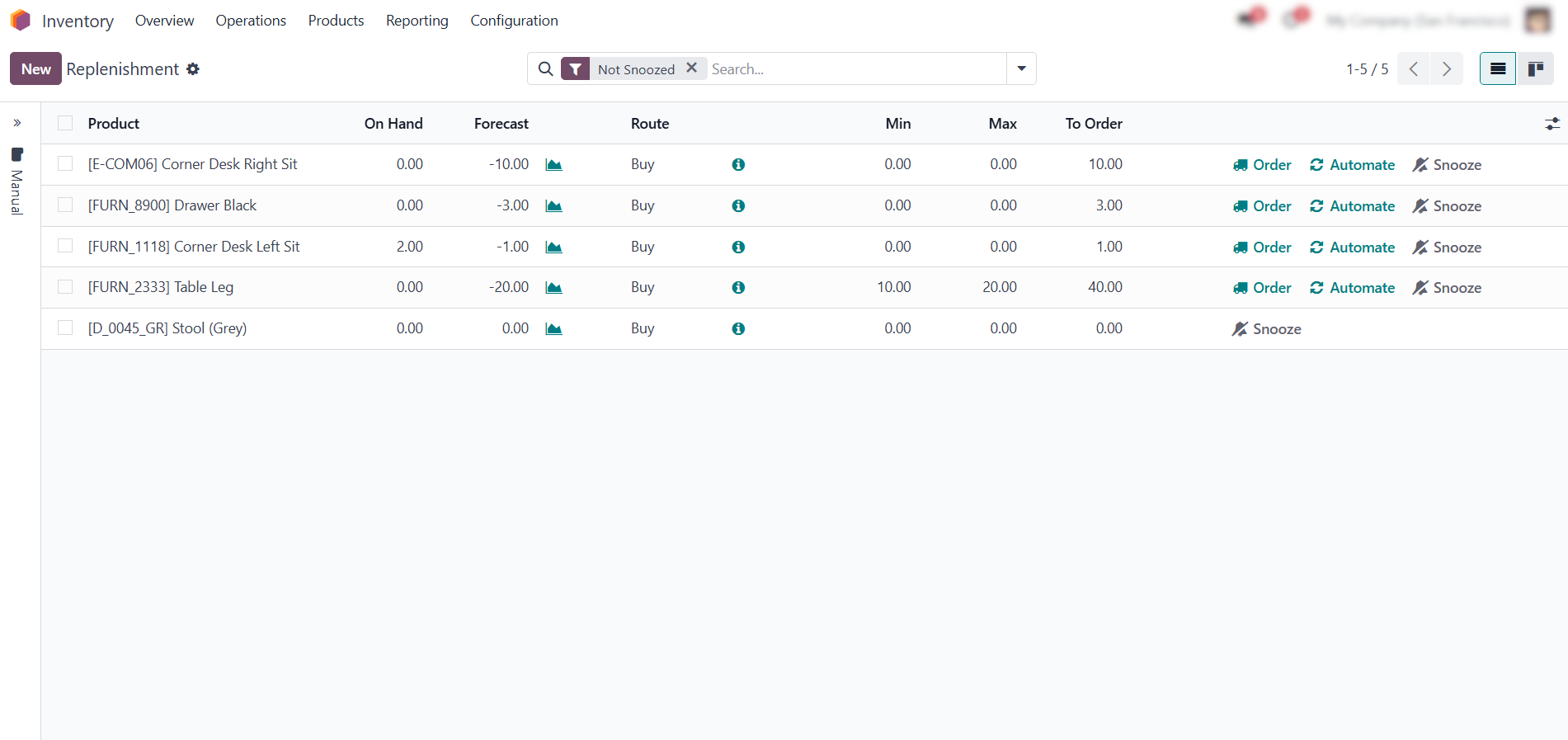

The replenishment report in Odoo 18 has been completely reworked to offer a clean, intuitive overview of all products needing restocking. It highlights replenishment triggers, whether based on reordering rules, lead times, or forecasted demand, and presents clear recommended actions. This empowers inventory managers to make faster, better-informed decisions with minimal manual effort. One glance at the dashboard now provides everything needed to take immediate action. While the new interface improves visibility, the real transformation lies in how much of the process can now run itself.

Full Automation with

Customizable Logic

The system allows organizations to fully automate replenishment work by defining smart rules tailored to each product. Whether triggering a purchase order, manufacturing order, or internal transfer, the system automatically initiates the appropriate supply chain response. For operations requiring human validation, partial automation models remain available. This ensures flexibility without sacrificing control. Building on this, Odoo 18 allows for more sophisticated planning by combining different replenishment approaches in a single workflow.

Hybrid Replenishment Strategy in Odoo

A key innovation in the system is the ability to combine Make-To-Order (MTO Odoo) with forecasted demand. This hybrid replenishment strategy ensures more accurate planning for variable or seasonal products while avoiding overstocking. It allows businesses to meet demand flexibly while optimizing cash flow and reducing tied-up capital. Such a blended approach maximizes responsiveness and minimizes waste. Achieving such accuracy also depends on real-time coordination with suppliers.

Enhanced Lead Time and Supplier Integration

The new replenishment engine incorporates supplier lead times, reliability metrics, and real-time stock levels across multiple warehouses. This enables smarter prioritization of replenishment tasks, aligning purchasing decisions with actual supply chain performance. Better supplier insights lead to better purchasing outcomes. Ultimately, all these enhancements work together to elevate stock replenish into a true strategic capability.

A More Strategic

Approach to Inventory Management

With these updates, the system transforms replenishment from a reactive process into strategic capability. Businesses can now anticipate demand, automate procurement, and optimize warehouse operations. All of this helps improve service levels and reduce operational risk. The system features turn the replenishment report into a key driver of supply chain success. As a result, replenishment becomes not just more efficient, but also more aligned with broader business goals.

Getting

Started with Replenishment Inventory

Setting up a replenishment inventory system in Odoo 18 starts with understanding the available replenishment triggers and how they align with your stock management strategy. Replenishment operations in the system can be initiated in two distinct yet complementary ways, offering flexibility for various inventory management workflows. Users can initiate replenishment directly from the product management view. Alternatively, replenishment actions can be created centrally from the "Inventory" module, where users can generate new replenishment orders in bulk, based on stock rules, forecasted demand, or current stock levels. This dual approach allows businesses to tailor replenishment processes to their operational needs, whether managing exceptions manually or automating routine supply flows.

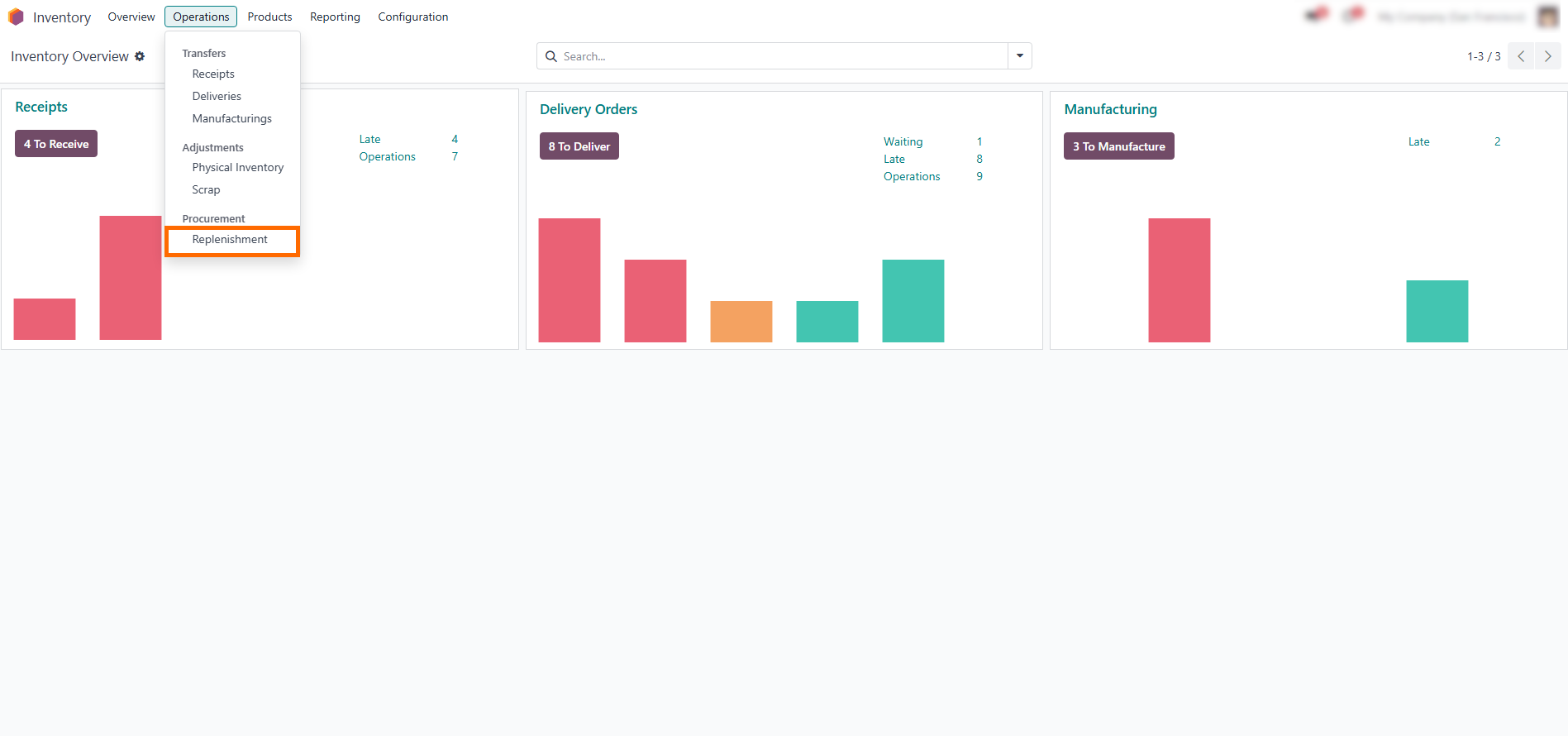

- In Odoo 18, users can access the replenishment of inventory

management windows from

the Operations tab.

- This window displays a list of pre-configured Odoo replenishment rules, which are easy to review and execute.

Creating

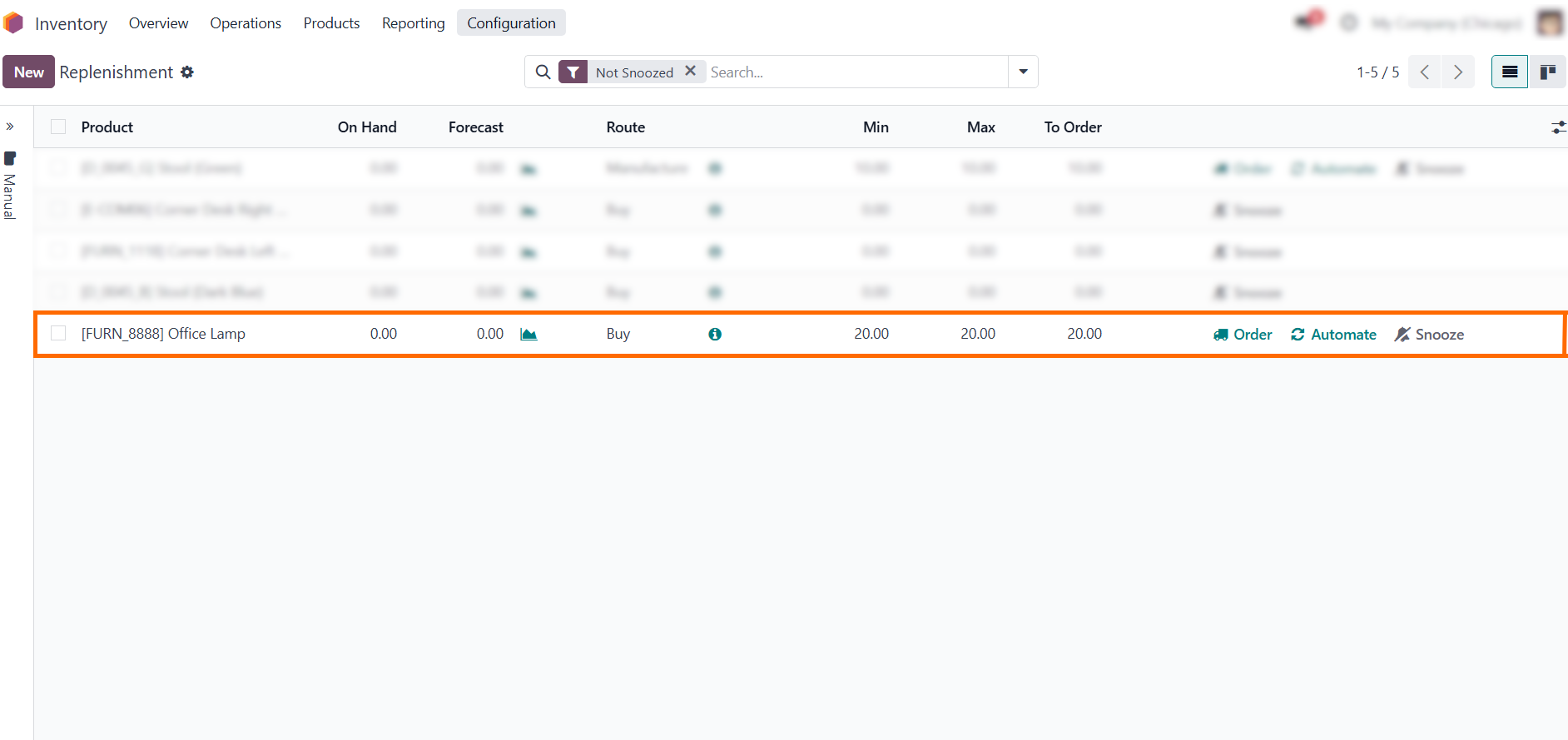

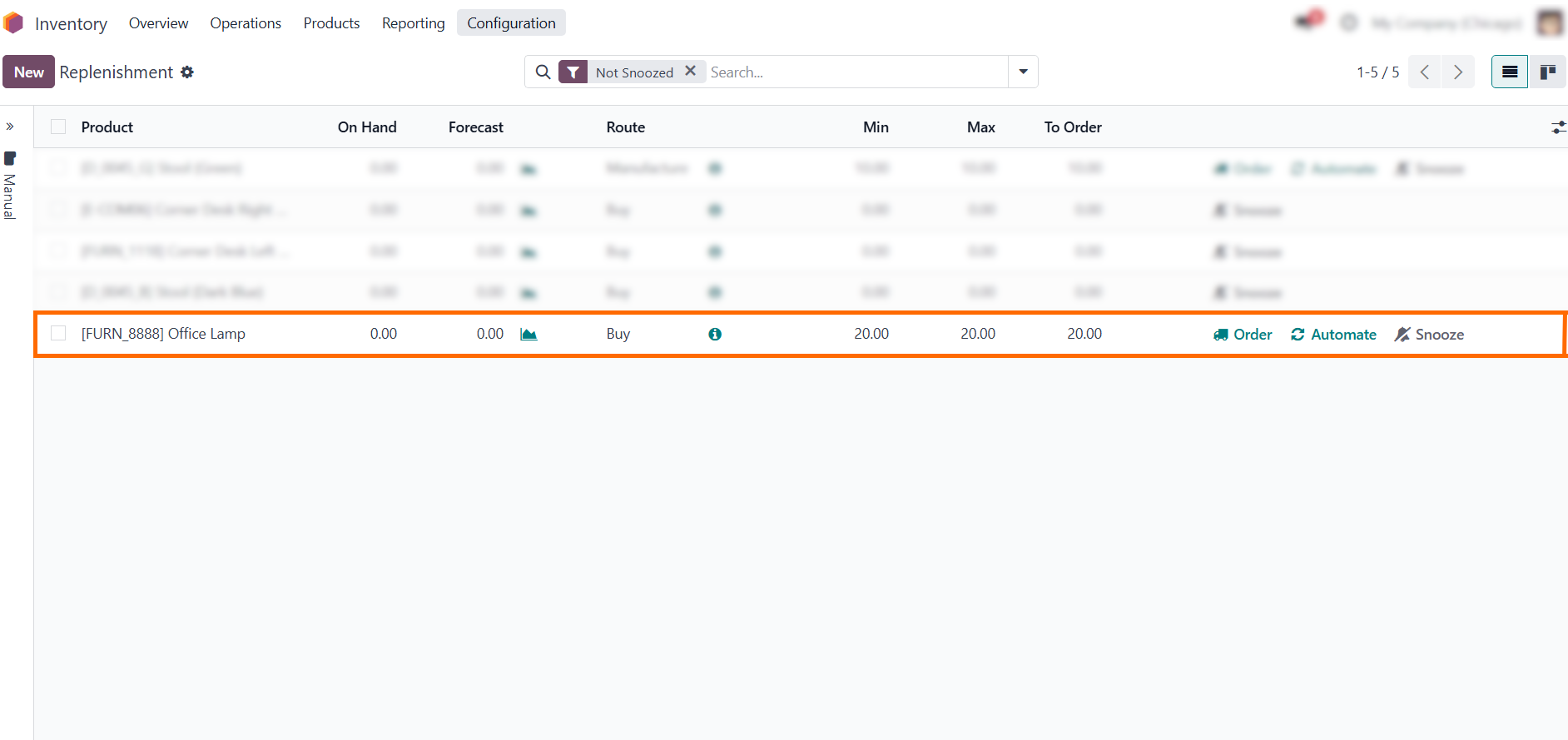

a New Odoo Replenishment Rule

Once the key parameters are understood, configuring a new rule becomes a simple configuration action within the product inventory settings. Setting up a product replenishment rule in Odoo 18 is a streamlined process that allows businesses to automate stock reordering based on predefined thresholds and supply chain logic. These rules define the minimum and maximum replenish stock levels for the products, as well as preferred procurement methods, such as purchasing, manufacturing, or internal transfer. By configuring smart reordering parameters, users can ensure timely replenishment without constant manual oversight. The foundational setup ensures that inventory levels are maintained automatically according to business needs, laying the groundwork for efficient procurement and warehouse operations.

- Click on “New” to create a new replenishment rule, as shown in orange in the interface.

Define key inventory parameters: reorder point, target stock level, order rounding rules, and

supply delay.

Triggering Product Replenishment in Odoo

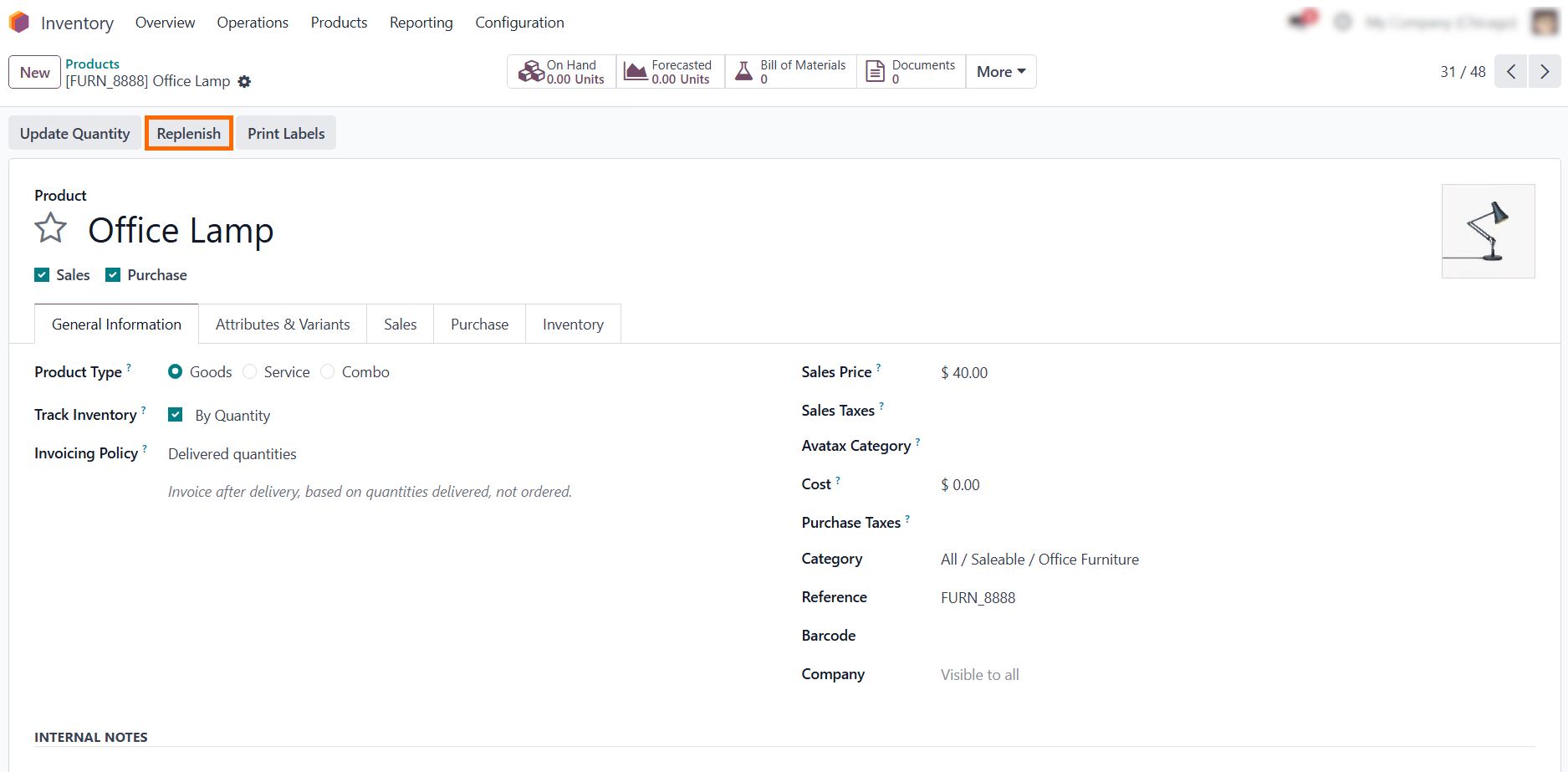

As mentioned earlier, Odoo 18 allows users to initiate replenish product directly from the product menu, streamlining inventory control for individual items. By navigating to a specific product and accessing the Inventory tab, users can configure reordering rules or trigger manual replenishment with a single click using the "Replenish" button. This feature is especially valuable for inventory managers handling exception-based or high-priority replenishment, enabling fast response without the need to navigate through centralized dashboards. This streamlined workflow enhances operational responsiveness, allowing inventory teams to address stock shortages in real-time and keep fast-moving items consistently available.

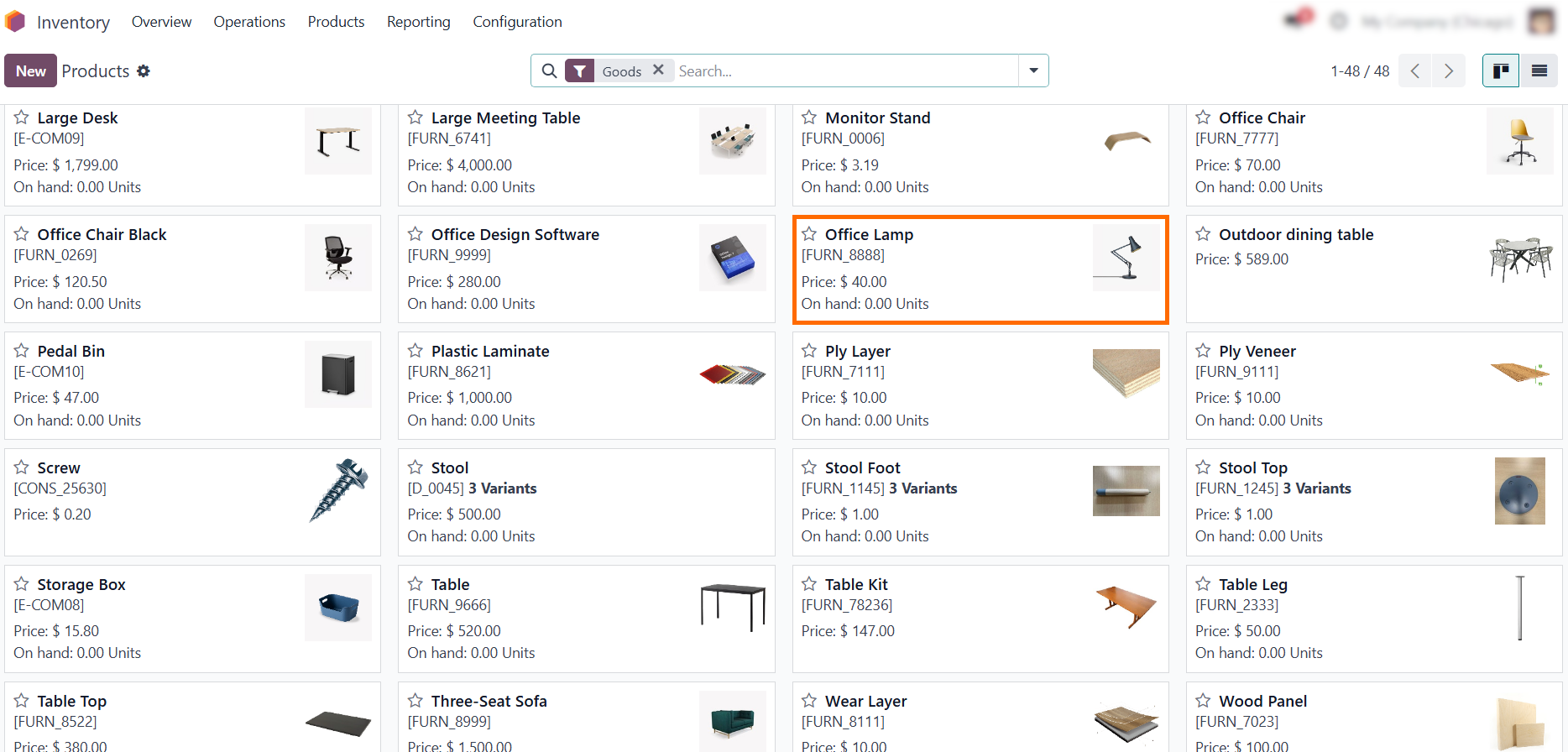

- Select the product in the Inventory Products tab for which you want to create a replenishment order.

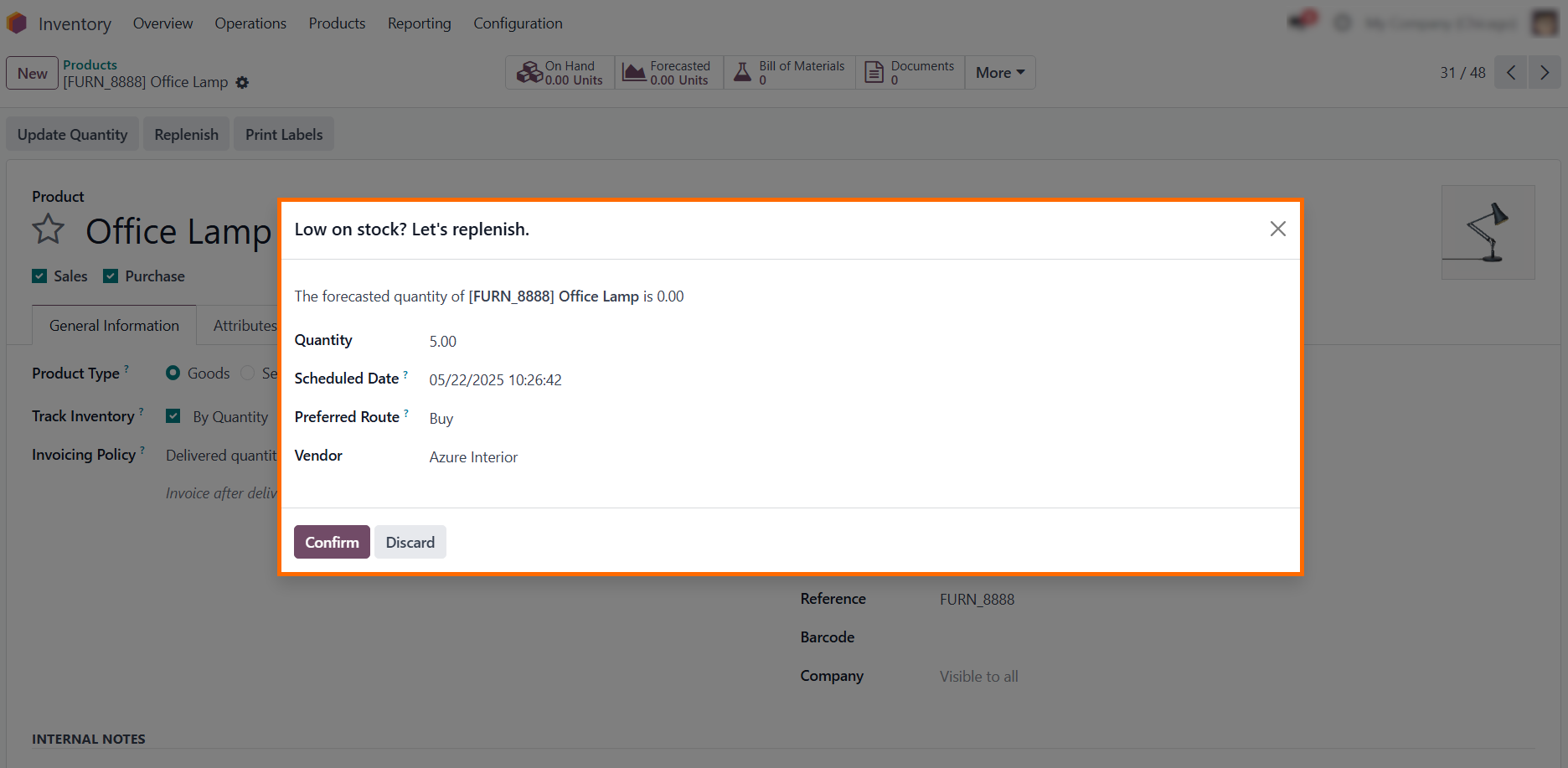

Click the "Replenish" button on the product form, as shown in orange for easy access.

- In the replenishment form, specify the quantity, scheduled date, and vendor, as this case involves purchasing finished goods rather than manufacturing them.

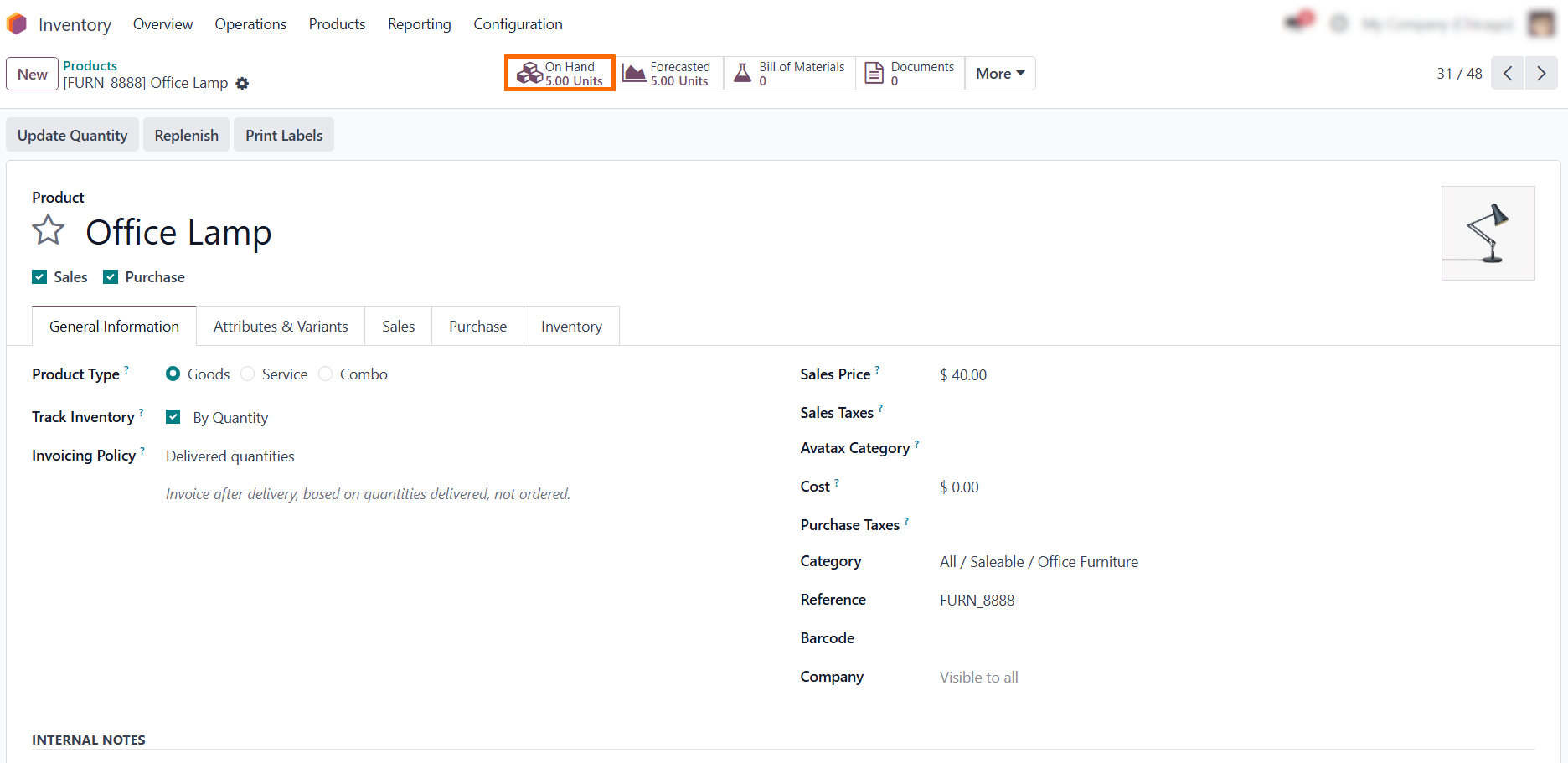

After the receipt is validated, Odoo 18 will automatically update the on-hand quantity, ensuring real-time inventory accuracy.

Practical Examples of Odoo Replenishment in Sales

Replenishment of inventory in Odoo 18 adapts to a wide range of operational strategies. The replenishment features can be tailored to match different operational workflows. For example, a business using a kanban replenishment strategy can benefit from the system’s ability to automatically generate replenishment requests based on visual stock indicators. In fast-moving environments, predefined rules help maintain optimal stock levels without manual intervention, ensuring the right replenishment amount is ordered just in time. For seasonal or unpredictable demand, companies can rely on a hybrid setup using forecasting tools. This helps avoid overstocking while still meeting customer expectations. The process is intuitive and requires only a few clicks.

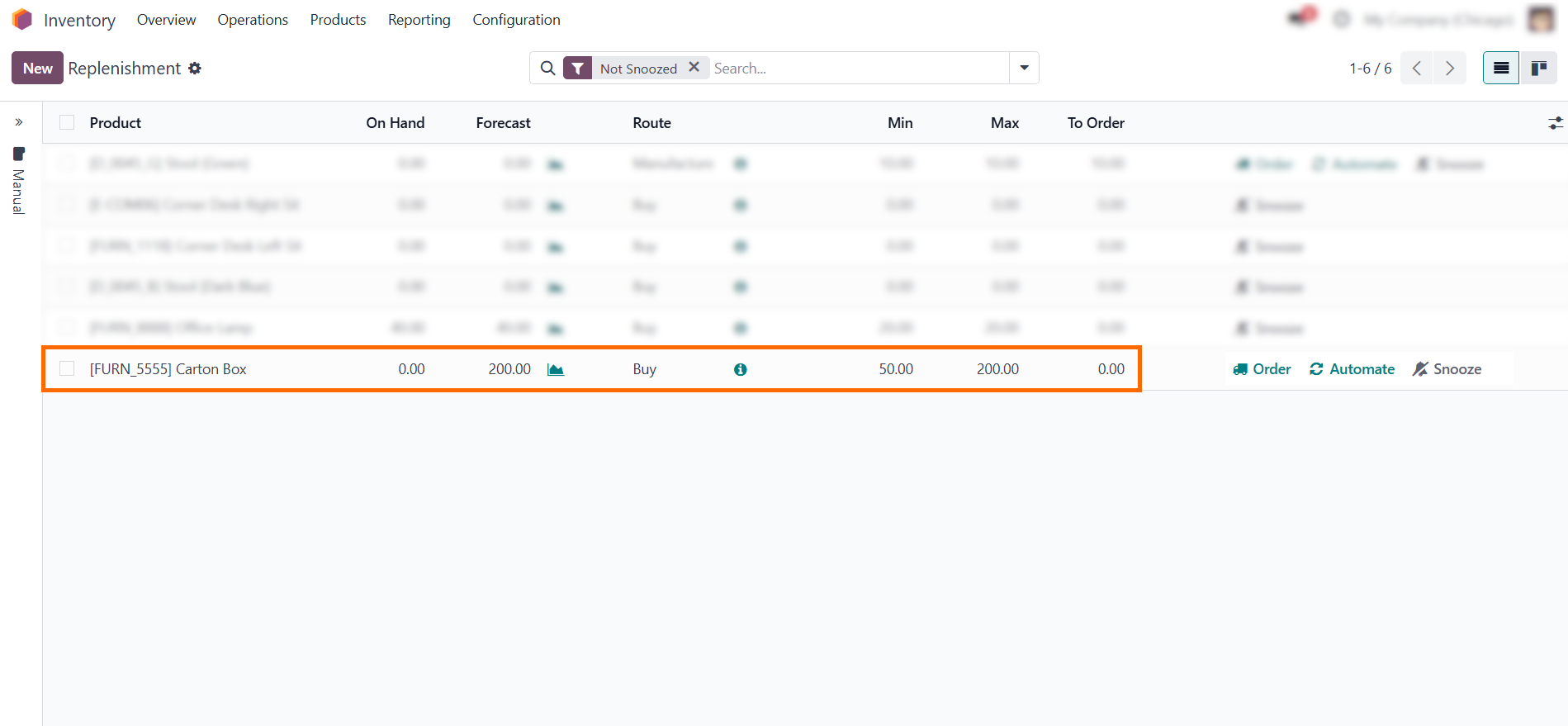

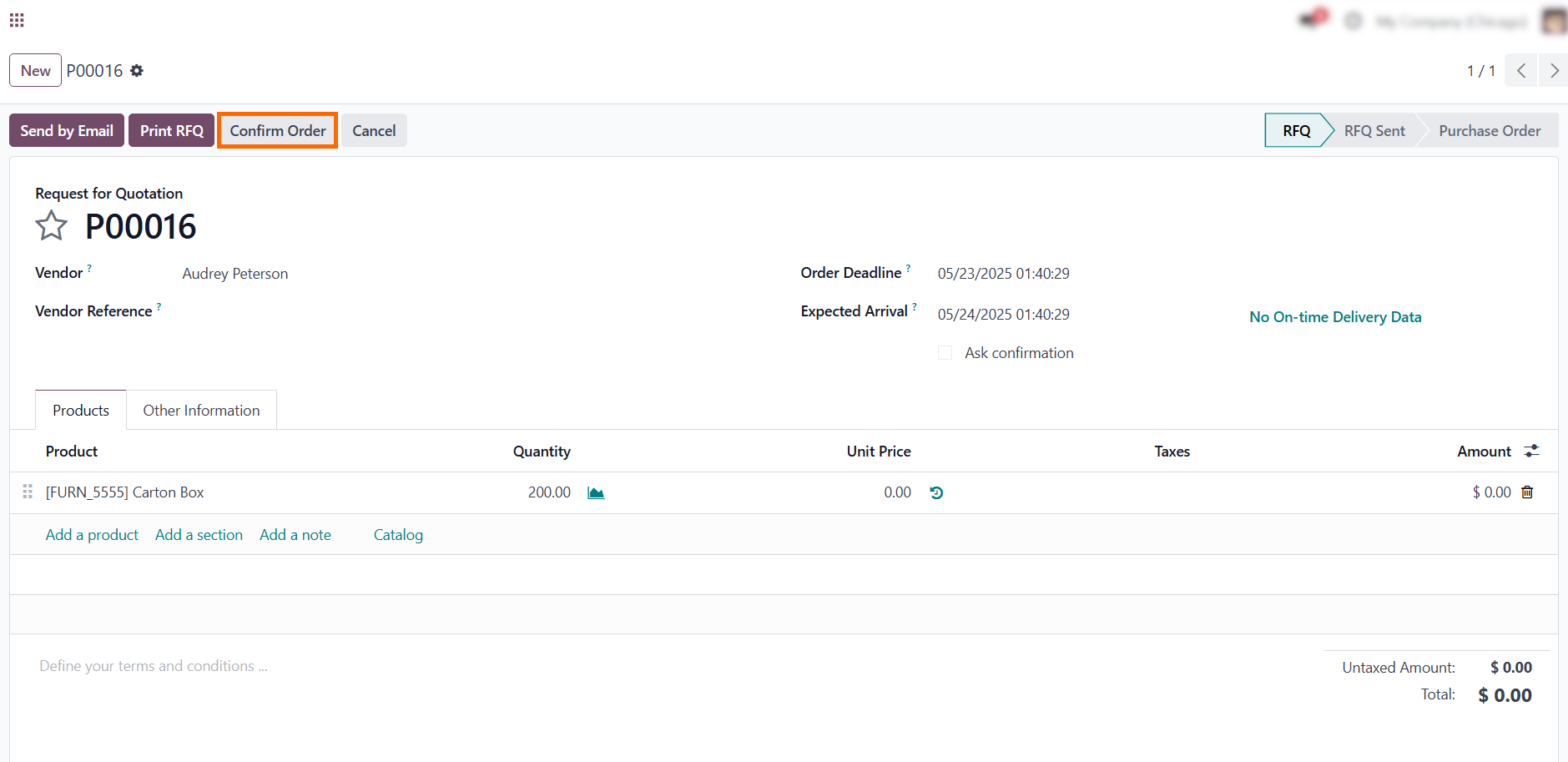

- As soon as the available stock drops below 50 units, the system automatically creates a draft purchase order to restore the stock up to 200 units.

- The procurement team only needs to review and

submit the purchase order, reducing

delays and manual workload.

Practical Examples of Odoo Replenishment in Manufacturing

For example, a manufacturing company can configure Odoo 18 to automatically trigger production orders when goods drop below a predefined replenish amount, aligning procurement, work orders, and lead times without manual interference. This is especially powerful for companies using the Odoo Make to Stock strategy, where maintaining a consistent inventory level is critical to ensuring uninterrupted production. In this way, replenishment becomes a dynamic feedback loop between planning and execution, enabling smarter decision-making and faster fulfillment. This not only improves operational continuity but also frees up human resources from routine stock monitoring, allowing planners to focus on strategic priorities.

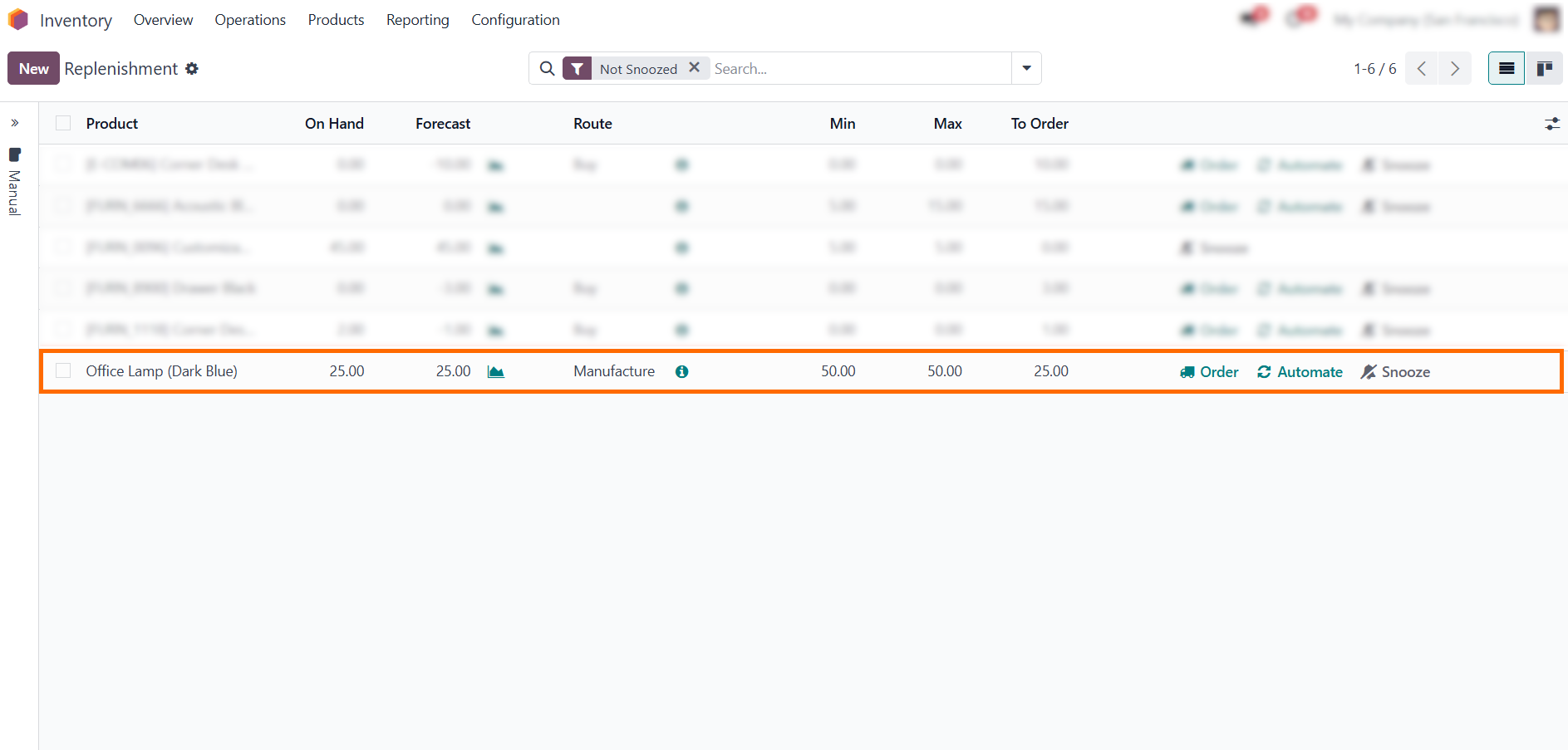

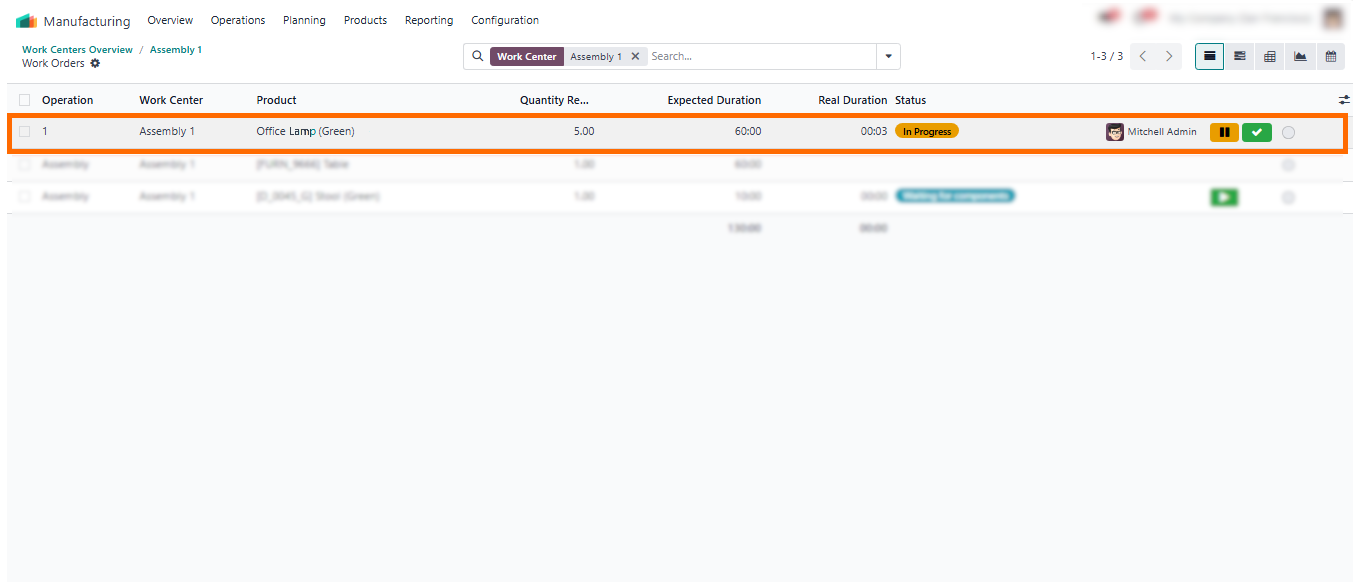

- Select the route type "Manufacture", as shown in orange. This sets replenishment to trigger a production order.

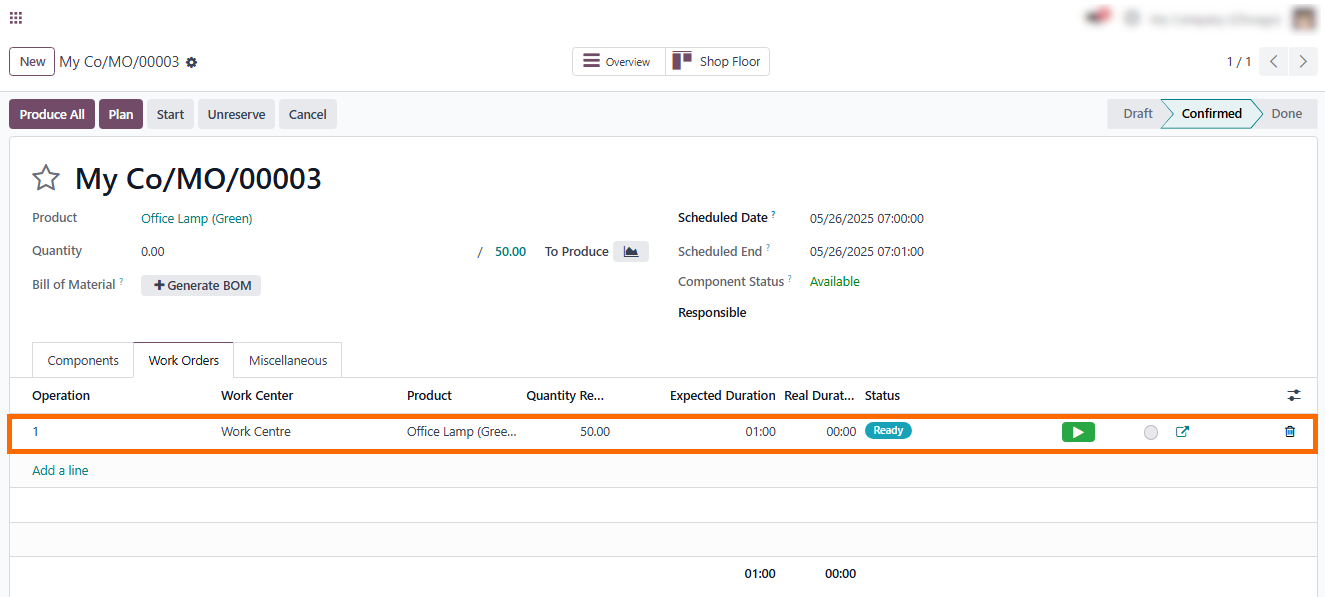

Once confirmed, the replenishment will trigger a draft manufacturing order that is complete with

materials, routing, and scheduling details.

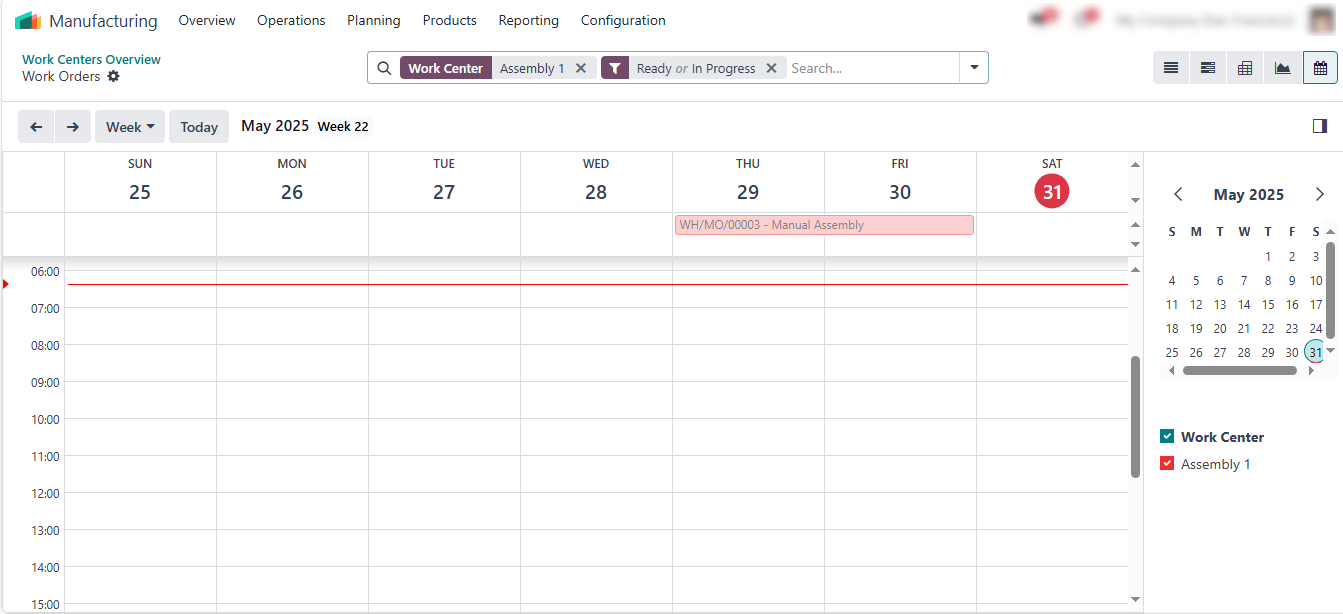

- Launch the production process directly from the manufacturing order. Once confirmed, Odoo 18 schedules the work order, allocates materials, and updates capacity planning in real time.

Leveraging Replenishment Analytics Tools in Odoo 18

The Odoo 18 system introduces a more analytical approach to inventory control, enabling businesses to understand not just when to restock, but why. Built-in reports allow users to review historical trends, monitor supplier performance, and fine-tune replenishment rules. This enhanced visibility improves forecasting accuracy and reduces guesswork, especially in hybrid workflows such as Odoo Make To Order. By analyzing what is replenish amount patterns and tracking each replenishment request, companies can continuously refine their stock policies and respond to demand more strategically. With every replenishment cycle, the system becomes smarter, adapting to changing demand signals and revealing inefficiencies before they escalate. These insights turn replenishment analytics into a continuous improvement engine, where data doesn’t just inform decisions but drives them.

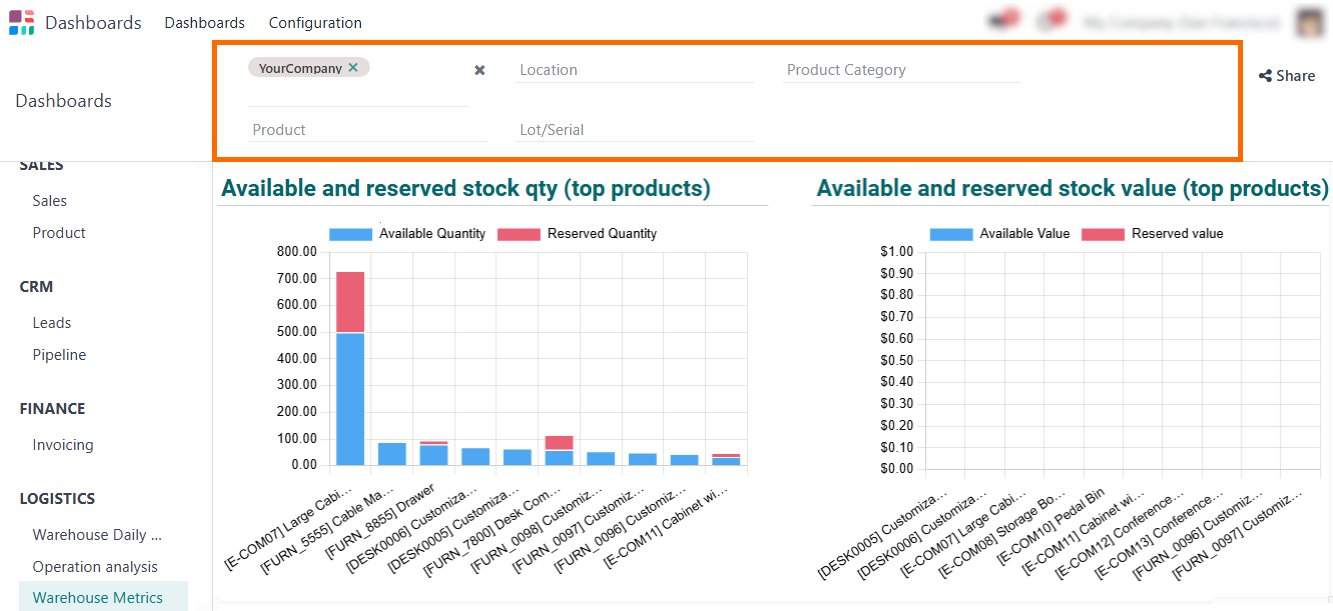

- Click on the Odoo Dashboard for a comprehensive analysis of inventory turnover, supplier reliability, and demand variance.

Use Filters to drill down into specific product categories or warehouses and view

stock replenishment trends over time.

Continuous Monitoring and Optimization in Odoo

Setting up replenish products rules is just the beginning — to maximize the benefits of Odoo 18, it is essential to regularly monitor replenishment performance and adjust parameters accordingly. Regularly reviewing stock levels, supplier lead times, demand fluctuations, and order fulfillment rates helps identify inefficiencies and prevent stock-outs or overstocking. Utilizing Odoo’s built-in analytics and reports, inventory managers can fine-tune reorder points, safety stock, and order quantities to reflect current market conditions and operational realities. Exporting replenishment reports for sharing with purchasing teams or supply chain managers supports collaborative decision-making and continuous process improvement. This ongoing optimization ensures that the replenishment process remains aligned with business goals and adapts to changing supply chain dynamics.

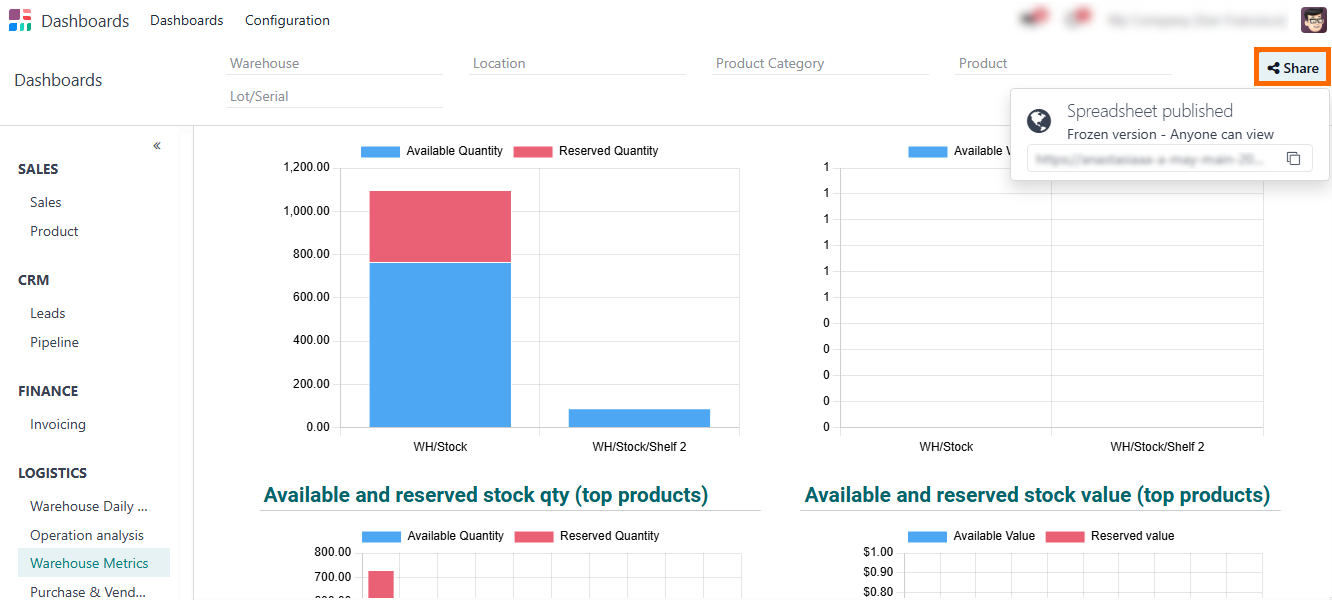

- Export Replenishment Reports to share with

purchasing teams or supply chain managers

for collaborative decision-making.

How Odoo’s Replenishment Algorithm Supports Inventory

Best Practices

Odoo

18 enables businesses to align their Make to Stock strategy with real-time

demand by integrating Odoo order

workflows directly into the replenishment process. With advanced replenishment

policies, the system automatically responds to sales, purchase, and

manufacturing orders by triggering the necessary stock actions. By linking

replenishment rules to sales forecasts, supplier lead times, and current replenish stock levels, Odoo 18 transforms

static inventory control into a dynamic, data-driven process. These

replenishment flows are fully integrated with core Odoo modules such as Sales,

Procurement, Manufacturing, and Accounting, creating a unified and seamless

inventory management system. The result is a smarter, faster, and more adaptive

supply chain that minimizes stock-outs, reduces manual intervention, and

supports long-term operational scalability.

- Users can simply click on the Reordering Rules for a product, then adjust supplier lead times via the calendar picker to reflect seasonal changes or updated delivery schedules.

Common Mistakes in Replenishment Odoo

While

Odoo’s replenishment items features

offer powerful automation and data-driven insights, businesses often fall short

in fully leveraging them due to strategic and operational missteps. These

errors not only undermine inventory performance but also lead to financial

inefficiencies, stock discrepancies, and diminished supplier trust. Below are

some of the most common pitfalls companies face when configuring or managing

replenishment rules in Odoo 18 and how to avoid them. Addressing these issues

early can significantly improve inventory accuracy, reduce overhead costs, and

enhance the overall efficiency of your supply chain operations. These mistakes

are especially prevalent during initial Odoo, when default settings are left

not optimized for the company’s actual supply chain dynamics.

Misunderstanding Replenishes Inventory and Its

Financial Implications

One of the most frequent missteps is a narrow interpretation of the replenish inventory definition—treating it merely as a process of refilling empty shelves. In a professional setting, the replenishment meaning in accounting refers to the strategic practice of maintaining stock levels aligned with financial goals and operational needs. Poor understanding of this concept often results in excessive inventory carrying costs, tied up working capital, and imbalanced financial reporting.

Applying a Uniform Replenishment Method Across Diverse Product Categories

A common oversight in Odoo implementations is the use of a single replenishment method across all SKUs. This one-size-fits-all approach disregards product variability in demand cycles, shelf life, and supply volatility. For example, treating make to stock and make to order Odoo items identically can generate costly inefficiencies. Best practice requires classifying products and aligning each with an appropriate method.

Neglecting Replenish Records and Historical Consumption Data

Effective inventory management in Odoo depends heavily on robust data governance. Failing to maintain accurate replenish records, including lead times, reorder history, and minimum stock levels, is a critical mistake. Additionally, without documented procedures for documenting replenishment processes, operational teams lack consistency, especially in multi-location warehouses or retail outlets. This can trigger inventory discrepancies, missed sales, and compliance risks during audits.

Uncertainty Around What Is Replenishment Order

A surprisingly common problem is the lack of clarity around procedures for replenishing stock on display and its role in the procurement workflow. Users unfamiliar with this concept often create duplicate or mistimed orders, undermining warehouse and supplier coordination. In Odoo 18, a replenishment order should be a calculated, system-triggered action based on predefined thresholds and rules is not a result of manual guesswork. Without clear protocols, supply chain teams risk inefficiency and eroding supplier trust.

Over-reliance on Automation

Without Regular Calibration

Implementing an automated replenishment system can dramatically streamline operations, but it must not operate in a vacuum. Over time, supplier performance, product seasonality, and demand patterns change. If your organization relies on outdated parameters, the system that replenishes inventory might inadvertently amplify inefficiencies. Conducting periodic reviews of your replenishment algorithm, safety stock levels, and forecast accuracy ensures that automation continues to support rather than hinder business goals.

Conclusion

Implementing a smart inventory replenishment process in Odoo 18 offers significant opportunities to enhance inventory accuracy, streamline the supply chain, and improve supplier coordination. Unlocking the full potential of Odoo’s MRP replenishment tools involves more than just enabling automatic rules. It requires understanding the nuances of your replenishment policy, procurement methods, and demand variability. Whether you’re following a Odoo MTS or Odoo MTO strategy, it’s essential to grasp the auto replenishment system definition and tailor it to your workflows.

Many companies start with basic automation but soon realize that without careful planning, even the best automatic replenishment definition can lead to overstocking, missed sales, or inefficient inventory turnover. This holistic approach to inventory replenishment transforms traditional static processes into agile, intelligent systems that not only respond to current demands but also anticipate future challenges, ensuring your supply chain remains both efficient and resilient.

With the support of advanced ERP systems like Odoo 18, the replenishment report is no longer a static, rule-based feature. Instead, becomes a dynamic, data-driven capability that unifies forecasting, procurement, and logistics into a proactive, real-time responsive function that supports long-term efficiency and resilience. We help businesses define how to replenish stock effectively by aligning their order workflows with real-word operations. From analyzing the inventory replenishment process flow chart to implementing advanced Odoo demand forecasting models, we ensure that your replenishment strategy grows with your business.