The manufacturing module in Odoo is one of the fundamental components of any production management system. It serves as a formal instruction to initiate manufacturing, specifying what to produce, which materials and resources are required, and how the production process should be carried out. This is where planning ends and real production begins. Without well-structured manufacturing orders, companies risk delays, resource waste, and reduced product quality.

In modern ERP systems like Odoo 18, a manufacturing order serves as a central hub that connects inventory, procurement, work centers, and planning. It enables full traceability, automates raw material reservations, tracks production progress in real time, and ensures that production aligns with customer demand and inventory levels. By integrating structure, traceability, and automation into the heart of production, manufacturing orders serve as the operational blueprint that turns strategy into execution.

This practical Odoo manufacturing tutorial explores how manufacturing orders work, what information they contain, and how to manage them efficiently in the system. We’ll also look at how automating workflows can improve manufacturing accuracy, reduce lead times, and boost overall operational efficiency. Whether you’re setting up a new production line or refining an existing workflow, understanding the inner workings of the Odoo manufacturing module is maintained of unlocking operational excellence.

Key Components of an Odoo Manufacturing Order

Manufacturing orders are structured and dynamic elements that drive the entire production workflow in Odoo 18. To successfully manage production, companies need to understand what information each Odoo order contains and how these elements interact. By mastering the structure of Odoo ERP manufacturing orders, companies can take full control of their production workflows. Whether you’re starting with a basic setup or diving into advanced features like Odoo make to order, understanding these core elements is essential for scaling operations efficiently. Each component plays a crucial role, but it’s their seamless integration that transforms disconnected tasks into a consistent, automated Odoo manufacturing pipeline.

Odoo 18 Production Order Process

Every manufacturing order begins with the definition of the finished product. This is the item your production process will create. It must be linked to a Bill of Materials that outlines exactly what materials and quantities are required. The system automatically associates the correct Bill of Materials with the selected product, ensuring consistency and reducing manual errors. This is the first and most critical step in launching production.

Quantity to Produce

The Odoo production module specifies how many units of the product need to be manufactured. This number directly influences raw material reservations, work order duration, and even scheduling at the work centers. Whether you’re producing one unit or several thousand, the system dynamically adjusts the required quantities based on this field. This figure determines the scale and pace of the entire manufacturing workflow.

Bill

of Materials

The Bill of Materials is a crucial component that defines the structure of your product. It lists every raw material, component, and sub-assembly required to complete the manufacturing order process. This feature supports multiple Bill of Materials per product, making it easy to switch between production strategies. Once the manufacturing process is confirmed, the Bill of Materials drives material reservations and work order generation. It acts as the key to your product’s physical and operational structure.

Routing and Work

Orders

If the Bill of Materials includes routing, Odoo manufacturing automatically generates individual tasks that need to be performed at specific work centers. These work orders are scheduled based on resource availability, capacity planning, and production calendars. Each work order includes the operation name, the assigned work center, estimated duration, and real-time progress tracking, and optionally employee assignments. This helps break complex operations into manageable, trackable units.

Scheduling Odoo Production Planning

The Odoo production planning engine helps calculate start dates and deadlines for production based on lead times, work center availability, and routing paths. Whether you follow make to order Odoo or build-to-stock strategies, precise scheduling is essential to avoid bottlenecks and ensure timely delivery. For instance, if a routing includes heat treatment and assembly, each of these steps becomes independently manageable, allowing for better monitoring, accountability, and even subcontracting when needed.

Manufacturing Documentation

and Tutorials

For step-by-step guidance, the Odoo manufacturing documentation and community-contributed tutorials (including for Odoo 13 manufacturing tutorial or Odoo 14 manufacturing tutorial, and newer versions) offer in-depth explanations on configuration, automation, and optimization. Additionally, the official Odoo MRP documentation helps companies configure everything from work centers and routing to subcontracting and quality checks. These resources empower users to master the full potential of the system.

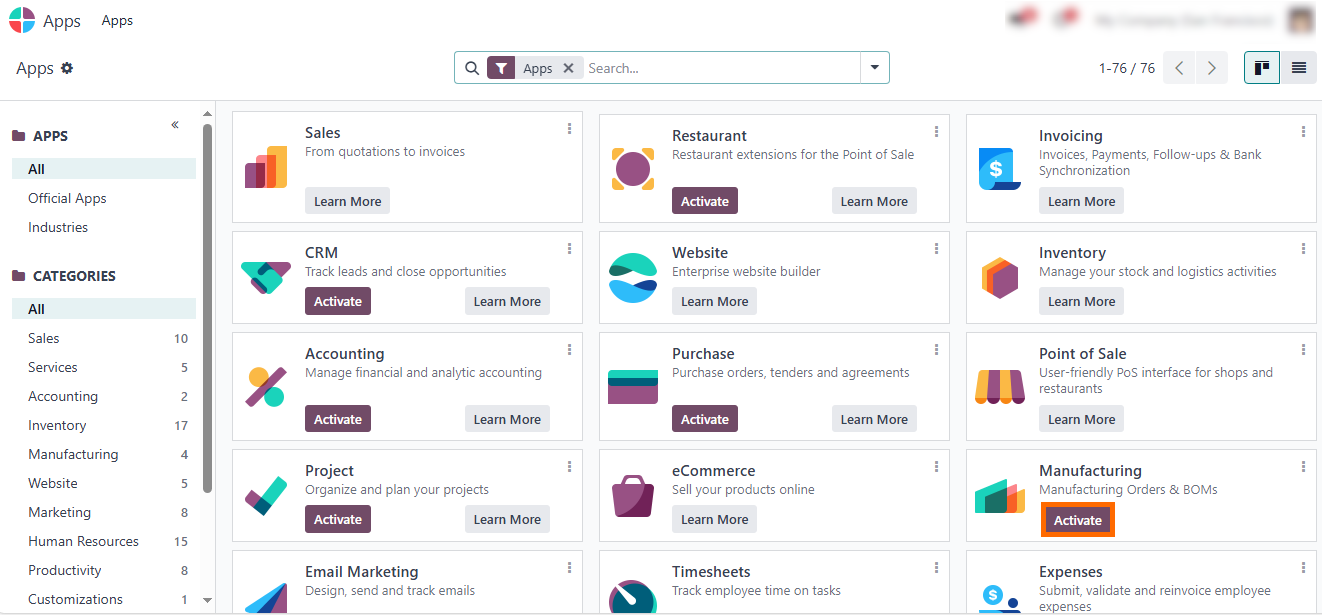

Preparing a Manufacturing Order

Before initiating manufacturing operations, the Odoo manufacturing module must be installed and configured. Companies can tailor the module to their operational model, whether they follow manufacturing for discrete assembly, Odoo food manufacturing, or hybrid production processes. Configuring the Manufacturing module sets the foundation for real-time production visibility, automated work orders, and cost-efficient operations, enabling manufacturers to stay agile in a competitive landscape. Once the module is activated, you can begin setting up your first production workflow. It’s recommended to begin with a small batch to validate your configuration, as even the most advanced production relies on a solid setup from the start.

- Go to the Apps

menu and install the Manufacturing module to unlock advanced Odoo

production management features.

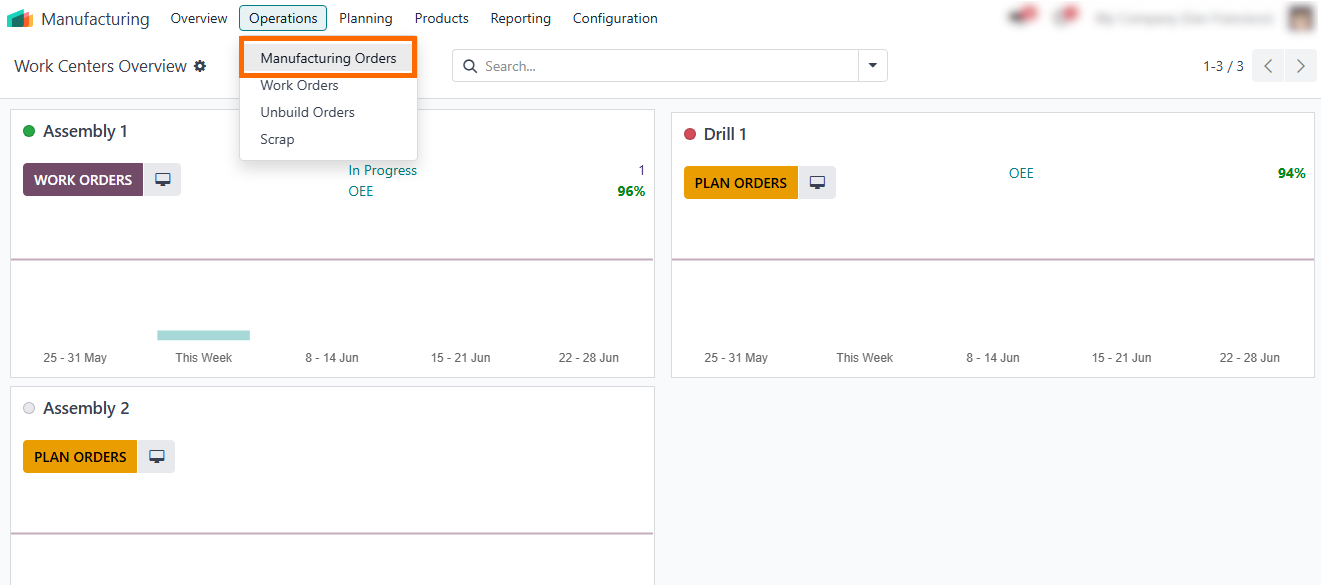

Smart Odoo Manufacturing Planning

Once the Manufacturing module is installed, the main dashboard becomes your operational control center. This intuitive interface provides direct access to all core manufacturing functionalities — manufacturing orders Odoo, Bills of Materials, Planning, Reporting, and more. From a single screen, production managers can initiate new orders, monitor up-to-date progress, identify bottlenecks, and take corrective action. The main dashboard is designed to offer full visibility and control across the entire Odoo production lifecycle, allowing companies to respond quickly to shifting demands, optimize capacity, and ensure alignment between production schedules and supply chain priorities. Odoo 18 centralizes production data to drive fast decisions and agile manufacturing.

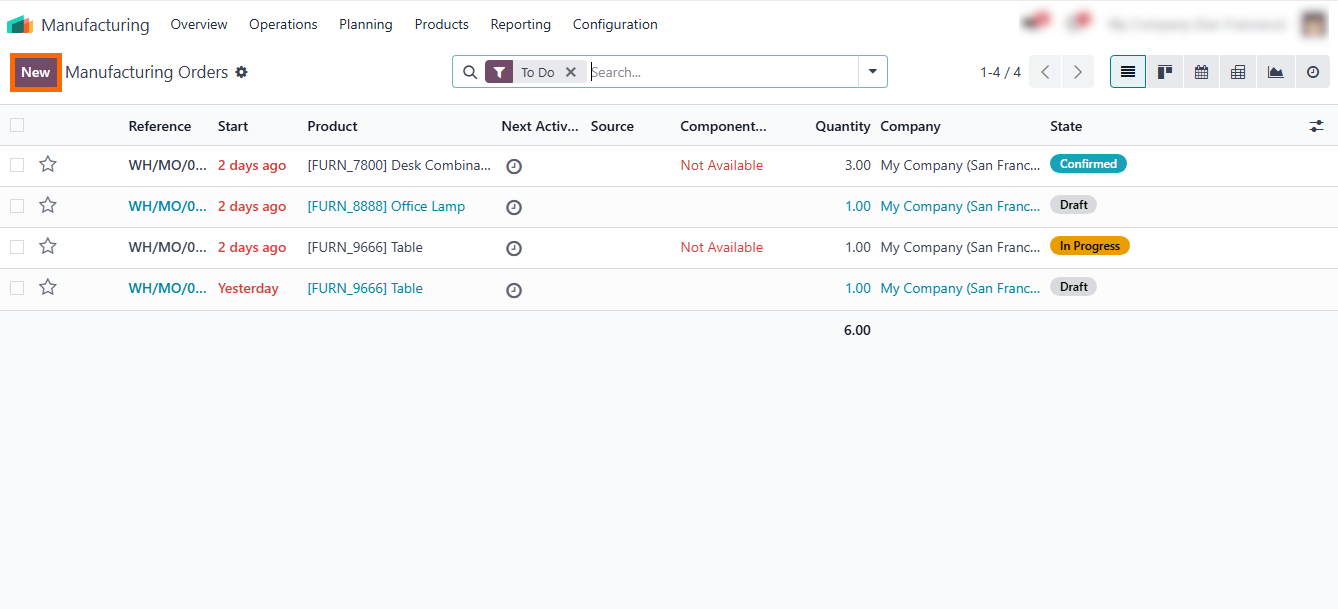

Click "Manufacturing Orders" to view existing orders, check their progress, or create a new one.

- This section allows teams to track each order’s status, access detailed production data, and launch new work orders. Click "New" to create a new manufacturing order.

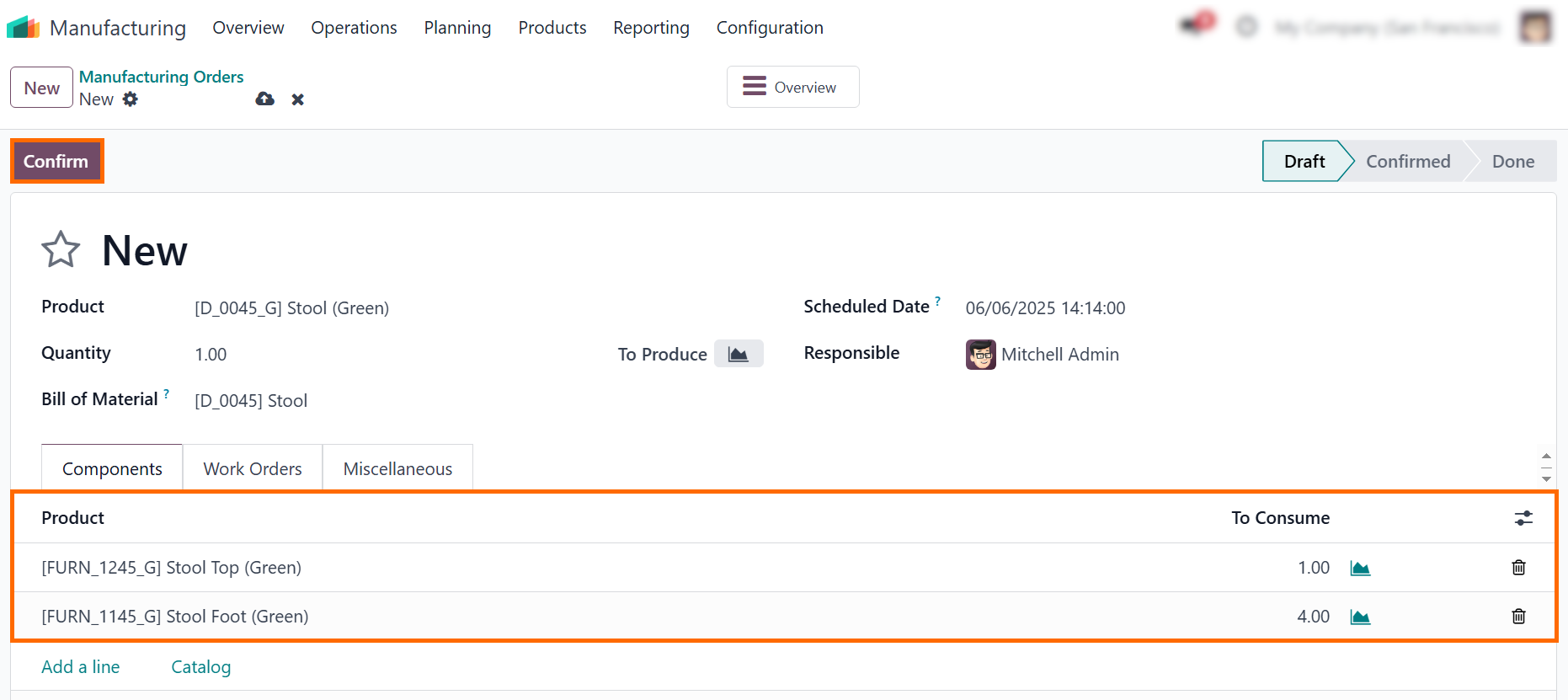

Manufacturing Order Definition in Odoo 18

Now that the system is ready and the planning dashboard is configured, let's move on to creating and managing the manufacturing process. This feature opens a clean and structured form where the product, quantity, Bill of Materials, and routing can be specified. The manufacturing order in Odoo automatically links relevant data such as available raw materials, associated operations, and work center capacity. Once the order is confirmed, the system reserves the required components, generates work orders, and schedules production according to availability and lead times. This streamlined process reduces manual input, eliminates errors, and ensures that manufacturing begins with all necessary resources aligned and ready, ensuring full control is maintained over every stage of production.

- Select the

product, quantity, scheduled date, and others. Afterward, the system will

automatically

display the required components.

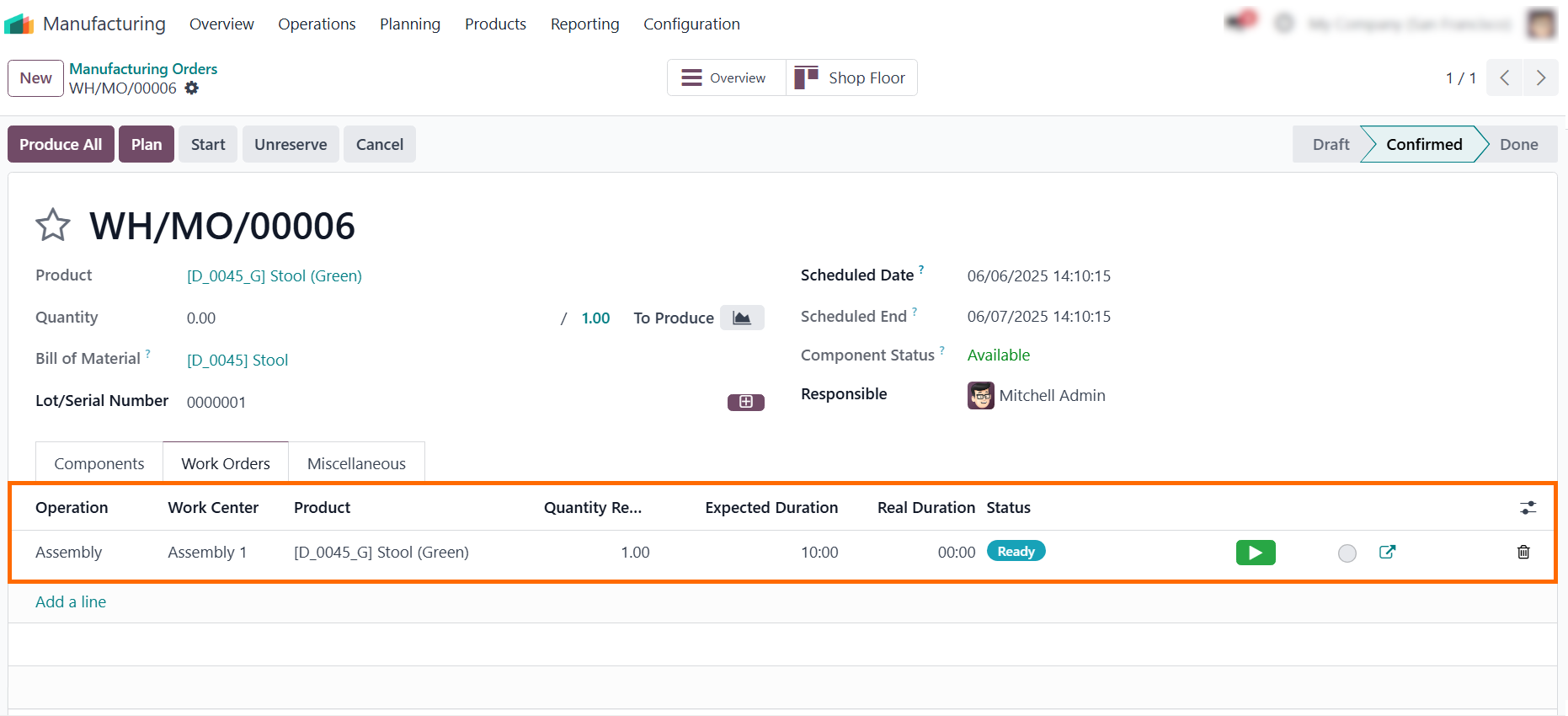

- The Work Orders field will also display all the operations required to complete the Odoo manufacturing process. This allows you to visualize the entire workflow status at every stage.

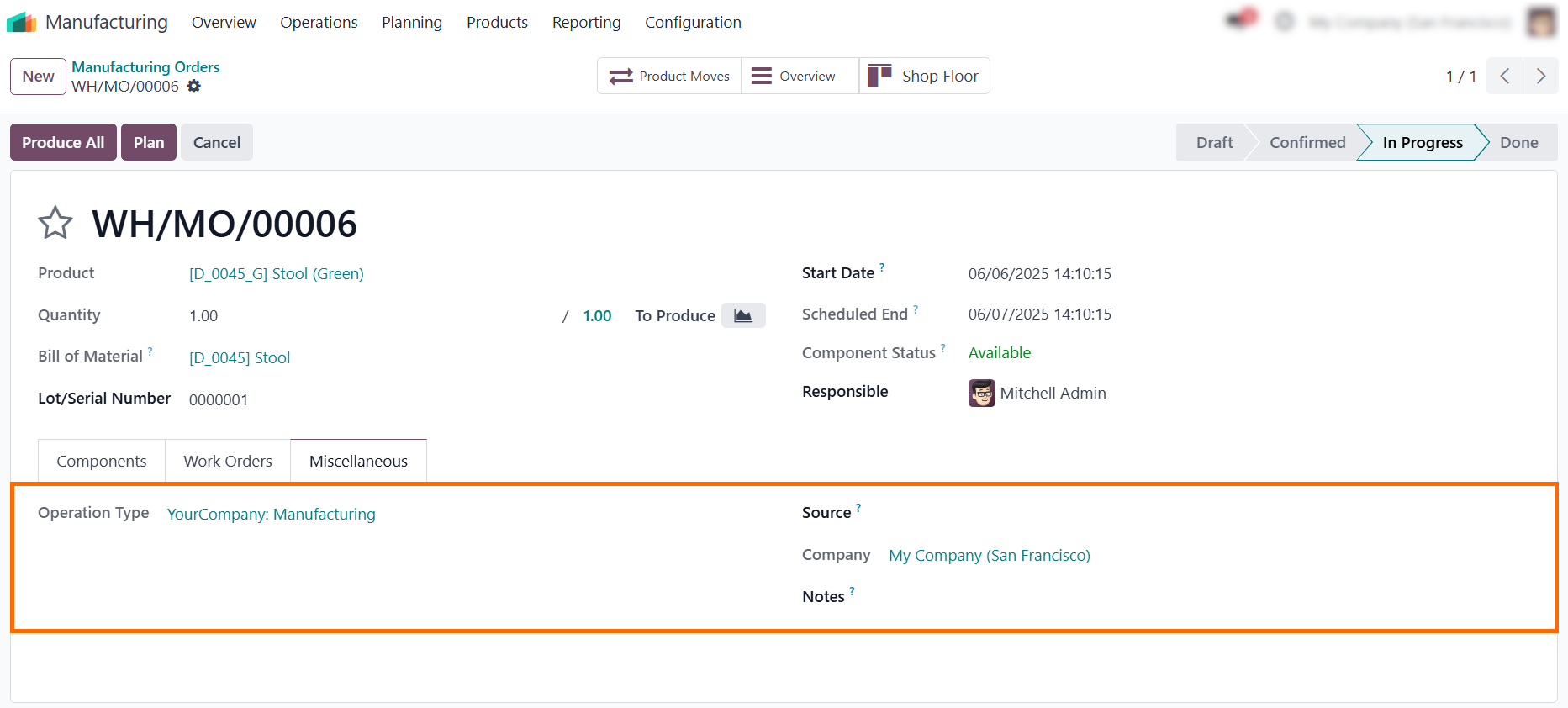

The "Miscellaneous" tab will display additional configuration options such as responsible users, tags, analytical accounts, and other custom fields.

Tracking

Odoo

Production Execution

Once a manufacturing order is confirmed, the real work process begins. That’s where Odoo production truly shines. From tracking real-time work order status to logging consumed materials and recording finished goods, Odoo 18 provides manufacturers with complete operational visibility. The system automatically updates production progress, links work center activities, and allows shop floor teams to use user-friendly interfaces for efficient task execution. Whether it’s monitoring live operations, identifying delays, or handling quality checks, the Odoo manufacturing module ensures that every step of the process is traceable, controlled, and optimized for performance. With smart automation and actionable insights, managing production becomes a streamlined, error-resistant experience.

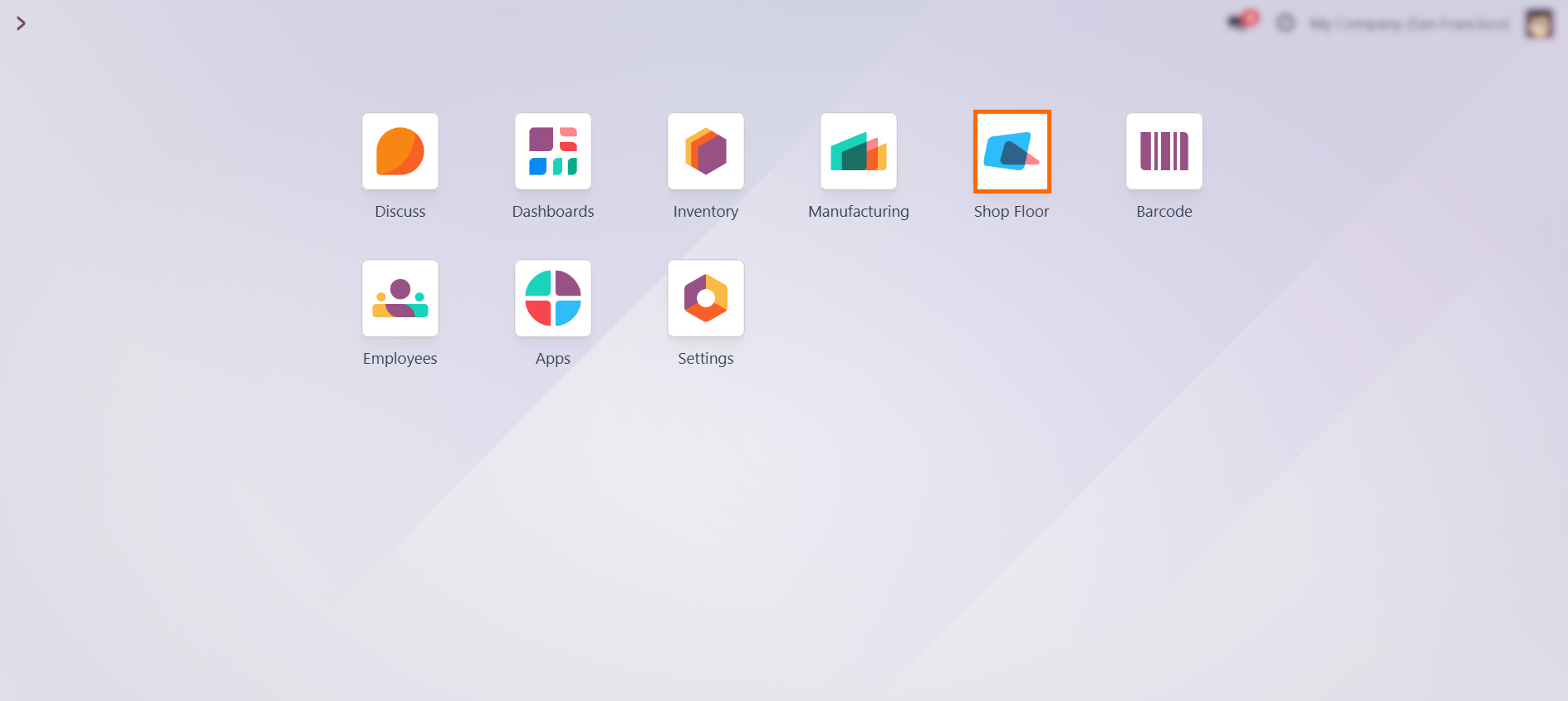

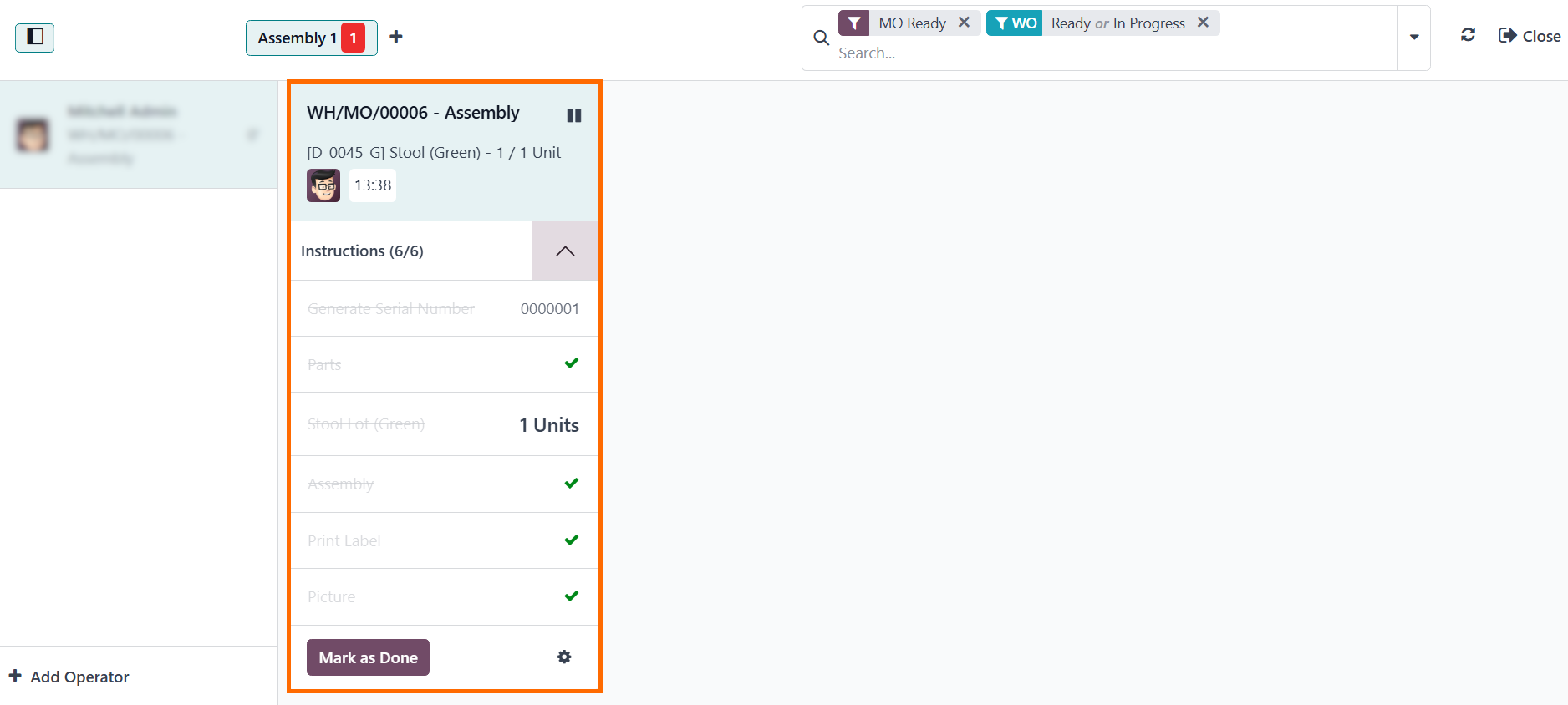

- Open the Shop Floor module to access the real-time production interface. There users can start, pause and complete work orders.

Click “Start Working” on the relevant Work Order – it appears as a card showing the

operation name, product, and scheduled quantity.

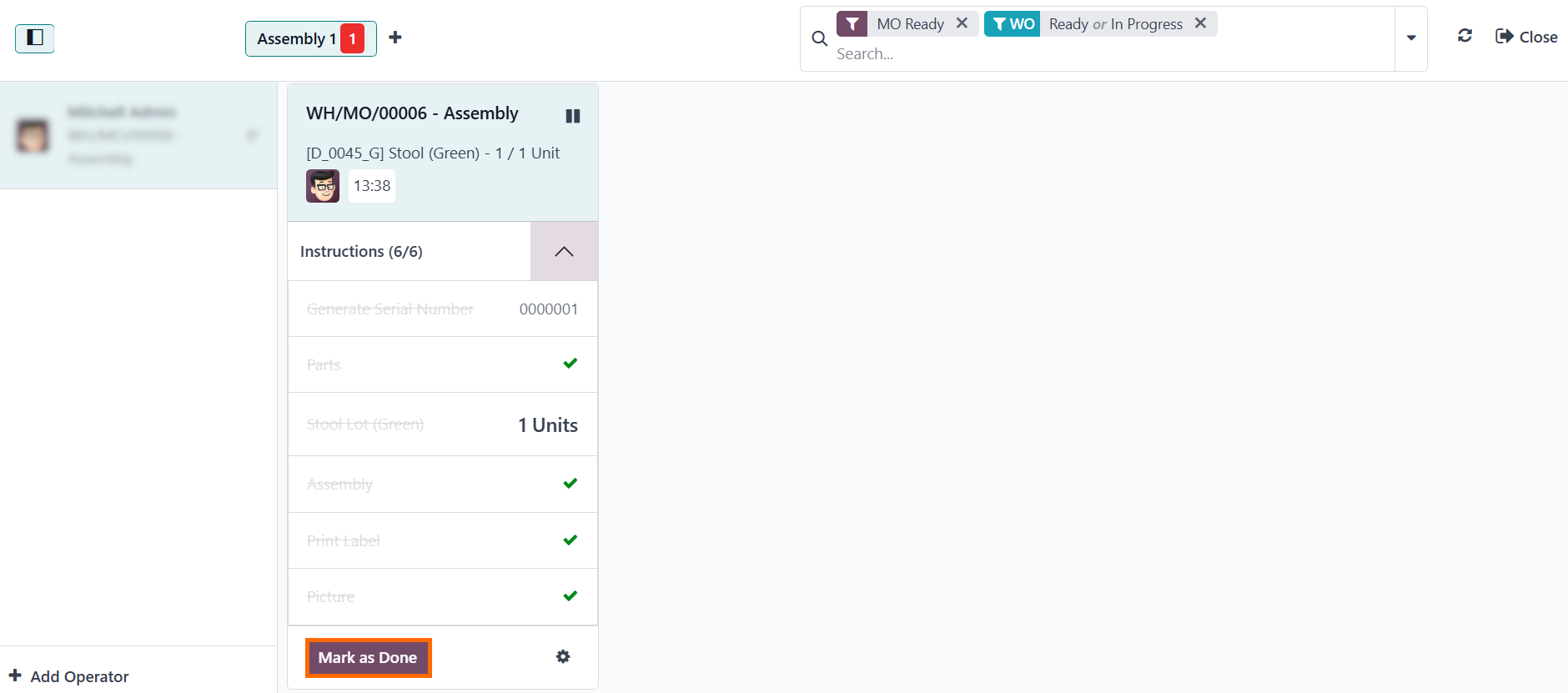

Closing a Manufacturing Order

Once all operations are completed, it’s time to finally close the manufacturing order. The Odoo manufacturing process makes this final step fast and seamless, ensuring that inventory levels are updated, finished products are recorded, and production data is stored for analysis. This step confirms that the goods are ready to be delivered or moved to stock. The system will update the status of the manufacturing order, post the finished goods to inventory, and logs all associated costs and time entries. It also generates valuable data for reporting and forecasting future forecasting demand. Accurate closure ensures that downstream processes like accounting, reporting, and reordering function without disruption. Before closing the order, it's crucial to review any discrepancies between expected and actual values, such as consumed materials, production duration, or productivity.

- Click “Mark as Done” to close

the Manufacturing Order. Once

closed, the manufacturing order

becomes a critical input for costing and performance analysis.

Costing and Valuation in

Odoo Manufacturing Order

After

a Manufacturing Order is completed, Odoo Manufacturing not only updates

inventory, but also records all relevant cost data. This includes consumed raw

materials, work center time, labor, and overhead. Accurately capturing Odoo produccion costs is essential for

maintaining profitability, evaluating performance, and supporting strategic

decision-making. By integrating analytic accounting companies can track costs

by project, department, or cost center, enabling detailed insights into

manufacturing efficiency and cost drivers. Real-time cost data allows managers to

compare planned versus actual expenses, identify variances, and optimize

resource allocation. This actionable analytics empowers better forecasting,

budgeting, and continuous improvement in manufacturing operations. With these

power insights, production teams can run what-if scenarios, evaluate

alternative routing, and even optimize supplier selection based on

cost-performance ratios.

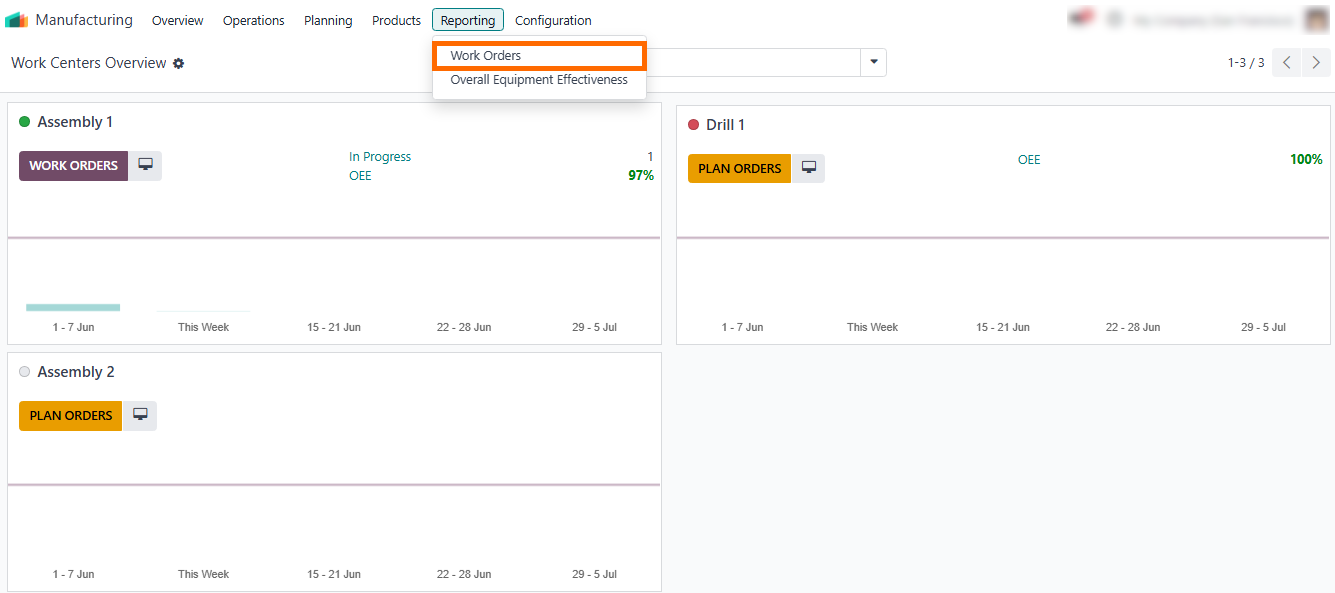

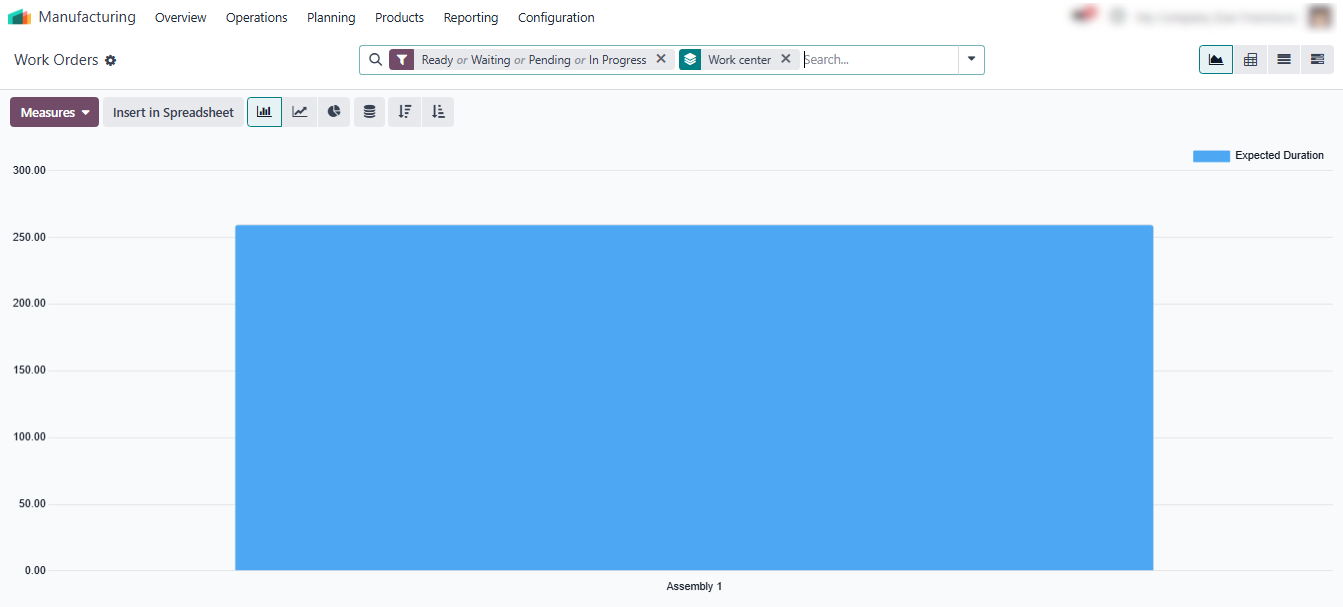

- Click "Reporting" and select "Work Orders". The selected report will be highlighted in orange, allowing you to easily identify it.

From there, you can analyze work order duration, operation efficiency, and performance metrics across your production workflow.

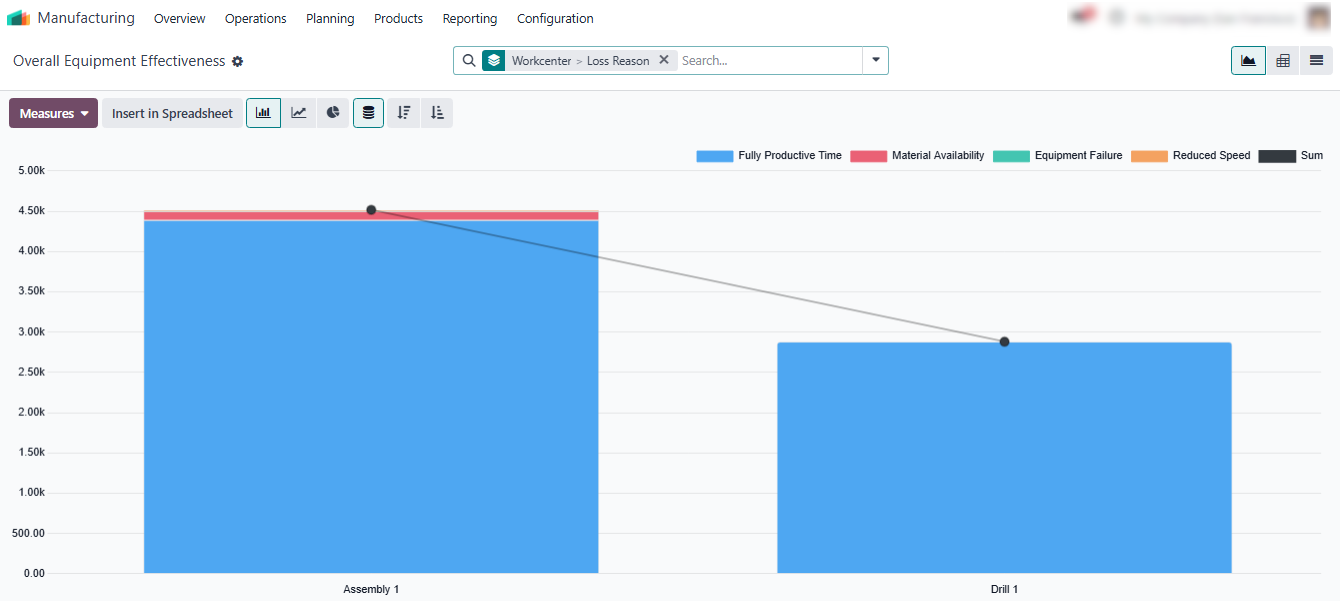

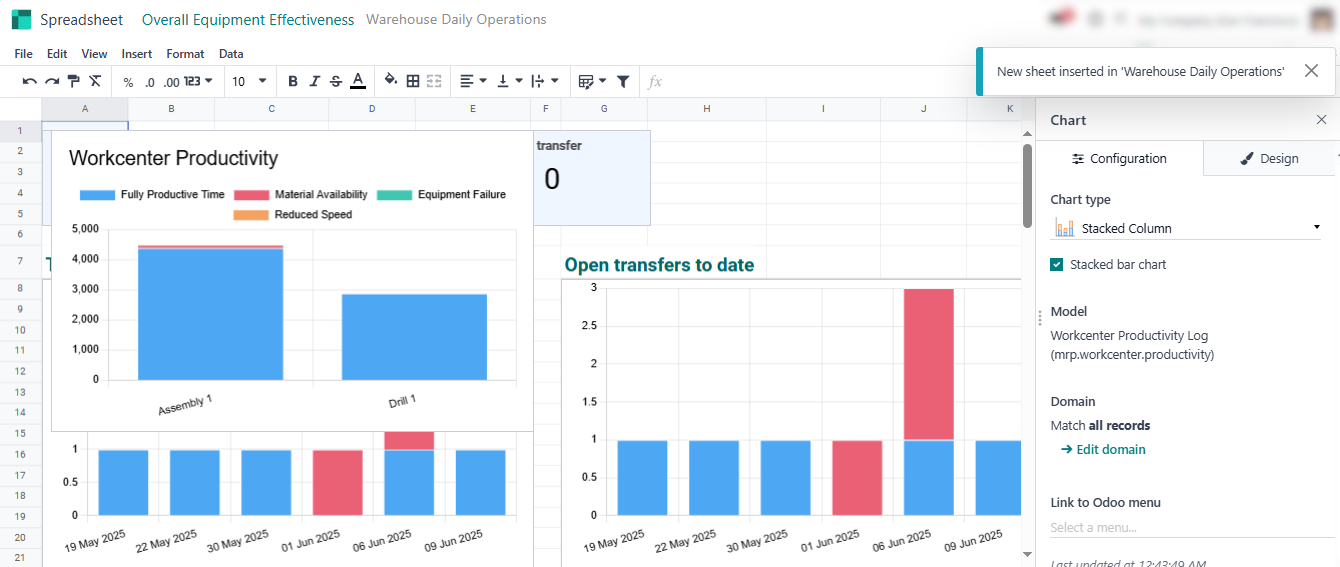

Overall Equipment Effectiveness is a high-level metric that measures production efficiency based on availability, performance, and quality.

-

Click

"Insert into Spreadsheet" in the report view to export the report

data. This allows teams to perform deeper performance reviews, visualize trends

over time.

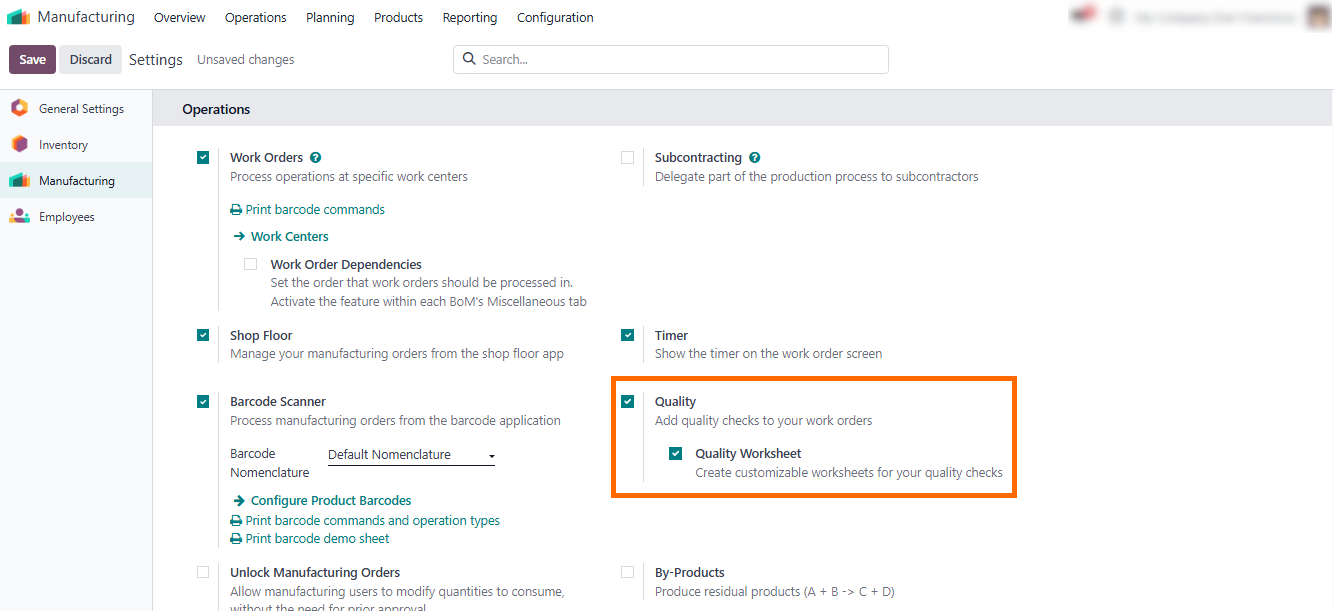

Quality Checks in Odoo Manufacturing

Maintaining production quality is critical in any manufacturing environment. Odoo manufacturing integrates robust quality management features that help ensure every product meets your standards before it reaches customers. Manufacturers can configure quality control points that trigger at specific stages of the production process. For example, during raw material intake, after a particular work order, or at final inspection. These checks can be manual or automated, and they ensure that no defective items proceed unnoticed through the workflow. By implementing quality alerts, control plans, and inspections, companies can standardize compliance procedures and reduce the risk of product recalls or customer dissatisfaction. With real-time quality monitoring and integrated reporting, manufacturers gain deeper insight into recurring defects, under-performing work centers, or problematic suppliers.

- Go to Configuration Settings

and activate the “Quality Checks” and “Work Orders” options if

they are not already enabled.

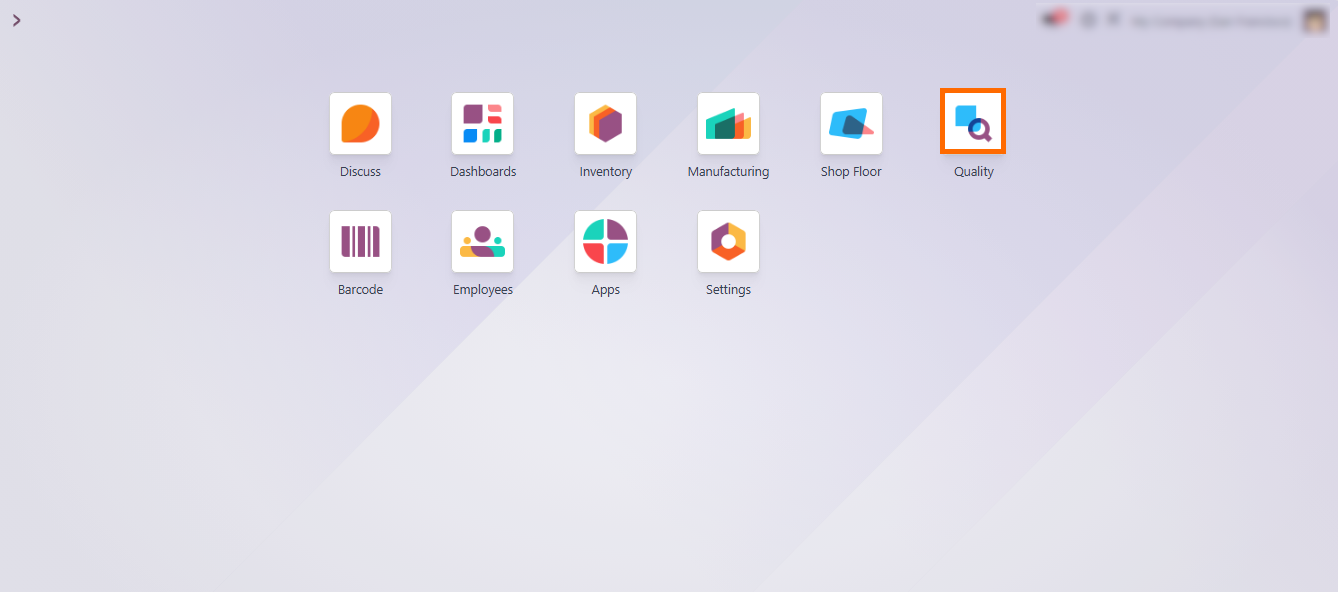

- The “Quality” module is now visible in the menu, confirming that quality control features are activated for use in manufacturing order.

Best Practices for Odoo Manufacturing Orders

These best practices are derived from real-world manufacturing use cases across industries like automotive, food production, and electronics. Success in manufacturing starts with discipline, not just data. Efficient manufacturing in Odoo depends not only on system setup but also on consistent execution. From accurate Bill of Materials to live tracking and automation, mastering everyday practices is what turns tools into results. These best practices help teams streamline operations, avoid costly errors, and maintain production accuracy at scale. They serve as a foundation for resilient, flexible manufacturing workflows that can quickly adapt to shifting demands. Whether you are managing small-batch custom jobs or large-scale process manufacturing, these habits ensure that your system implementation delivers measurable value.

Ensure Accurate Bill of Materials and Routings

Before confirming a manufacturing order, double-check the assigned Bill of Materials and Routing. Incomplete Bill of Materials or missing routing will prevent work order generation and disrupt raw material reservations. A single misconfigured component can delay production or cause quality issues across multiple orders. This is your first line of defense against production errors and waste. To strengthen control, by using approval workflows to avoid unauthorized Bill of Materials changes.

Align Scheduling with Odoo for Manufacturing

Use the Odoo production calendar to plan operations based on actual work center availability. Avoid overlapping tasks and ensure lead times are realistic. This ensures balanced workloads across resources and prevents last-minute rescheduling chaos. Smart scheduling prevents costly bottlenecks and downtime. Integrating time-off calendars and maintenance schedules into planning helps avoid unexpected capacity conflicts.

Automate Process from

Sales to Production

Enable automatic manufacturing order generation from confirmed Sales Orders, and activate replenishment rules for raw materials. This tight integration between modules reduces manual effort and ensures demand-driven production planning. It also improves traceability and makes it easier to align production with changing customer priorities. Automation eliminates delays and keeps production closely tied to real demand. Combine this with reordering rules and lead time buffers to avoid and overstocking.

Implement In-Process

Quality Checks

Quality control should not wait until the final step. Define quality checkpoints after key operations or work orders. This helps detect and fix issues early, reducing scrap rates and rework costs. Early-stage checks save time, materials, and reputation. Catch mistakes when they're small, not when they’re costly. Regular checks also build a feedback loop that improves future production runs.

Leverage Real-Time

Dashboards

Use the Shop Floor app and analytic accounting to track work order execution, time, and costs. Odoo’s live dashboards and reports “Overall Equipment Effectiveness” help identify inefficiencies and drive continuous improvement. Live data leads to faster reactions and better outcomes. These metrics help managers make proactive decisions rather than relying on end-of-month reports.

Maintain Up-To-Date Work

Center

Odoo production module capacity evolves with time. Regularly review and update your work centers, routings, and lead times to reflect real-world changes, such as equipment upgrades, maintenance schedules, or shifts in workflows. Keeping these elements current ensures accurate planning and avoids unrealistic production timelines.

Use Version Control for

Bills of Materials

For companies that frequently update product designs, enabling versioning for Bills of Materials is crucial. Odoo manufacturing allows tracking multiple Bills of Materials versions per product, helping manufacturers trace changes, ensure regulatory compliance, and avoid errors from outdated structures. Assign analytic tags to Bill of Materials versions to evaluate cost impacts or performance different across iterations.

Conclusion

A clear understanding of the manufacturing orders definition is essential for companies aiming to improve production efficiency and scalability. In Odoo 18, manufacturing orders are not just documents but the central element that coordinates raw materials, work centers, and workflows to achieve business objectives accurately and flexibly. For process manufacturing co with complex products and regulatory demands, Odoo offers a solution that captures every detail of the production cycle. The seamless integration of Odoo sales order to manufacturing order ensures a smooth transition from demand to production. This reduces manual work, shortens lead times, and aligns inventory precisely with real demand, making operations more responsive and cost-effective.

Mastering manufacturing orders in the system gives real-time visibility into material reservations, work order progress, and final product delivery. This improves operational control and helps anticipate bottlenecks, optimize scheduling, and maintain consistent quality standards. Odoo manufacturing tools also include advanced costing and analytics, providing insights into production costs and efficiency. By fully leveraging Odoo manufacturing orders, businesses can automate key processes, eliminate production delays, reduce waste, and boost overall productivity.

As Odoo 18 continues to evolve, staying up to date with its manufacturing capabilities will ensure that your operations remain agile and competitive. Start optimizing your production workflows with Odoo production planning and transform your manufacturing operations with better planning, smarter execution, and more informed data-driven decisions. Unlock the full potential of manufacturing orders to drive business growth in today’s competitive market.